Setup and commissioning – Bell & Gossett P2001489 Integrated Technologic with Sensorless Control User Manual

Page 31

Setup and commissioning

WARNING:

System commissioning must be performed by qualified personnel.

• Ensure that all piping connections are made before commissioning the drive.

• Follow all start-up procedures for the motor, pump, and controller as indicated in their

respective manuals.

• Refer to the Technologic controller IOM for detailed information on controller

programming and parameters.

• Some default parameters are configured specially for the Integrated Sensorless

controller. The default parameters that are listed in the Technologic controller IOM

may be different.

• The motor parameters have been configured at the factory for the motor provided

with the Integrated Technologic Controller. Do not modify the motor parameters.

Modification of the motor parameters can result in malfunction of the sensorless

control algorithm.

Sensorless operation

This product has been equipped with sensorless control capability. This feature allows

control of a process variable (pressure or flow) without the need of installing an external

transducer. Sensorless control is intended for use in closed loop systems such as hydronic

circulating pump systems. Sensorless control is not intended for open loop systems. The

sensorless control method uses the relationship between head (pressure), flow, power

and speed (frequency) to determine the appropriate speed for the pump that is required

to maintain the process variable setpoint. Since these relationships change with the use of

different pumps and motors, pump performance data for the pump used must be

programmed in to the controller. This data has been pre-programmed in to the drive at

the factory to give the most accurate control possible. The controller is pre-configured at

the factory for sensorless pressure control (Set-up 3).

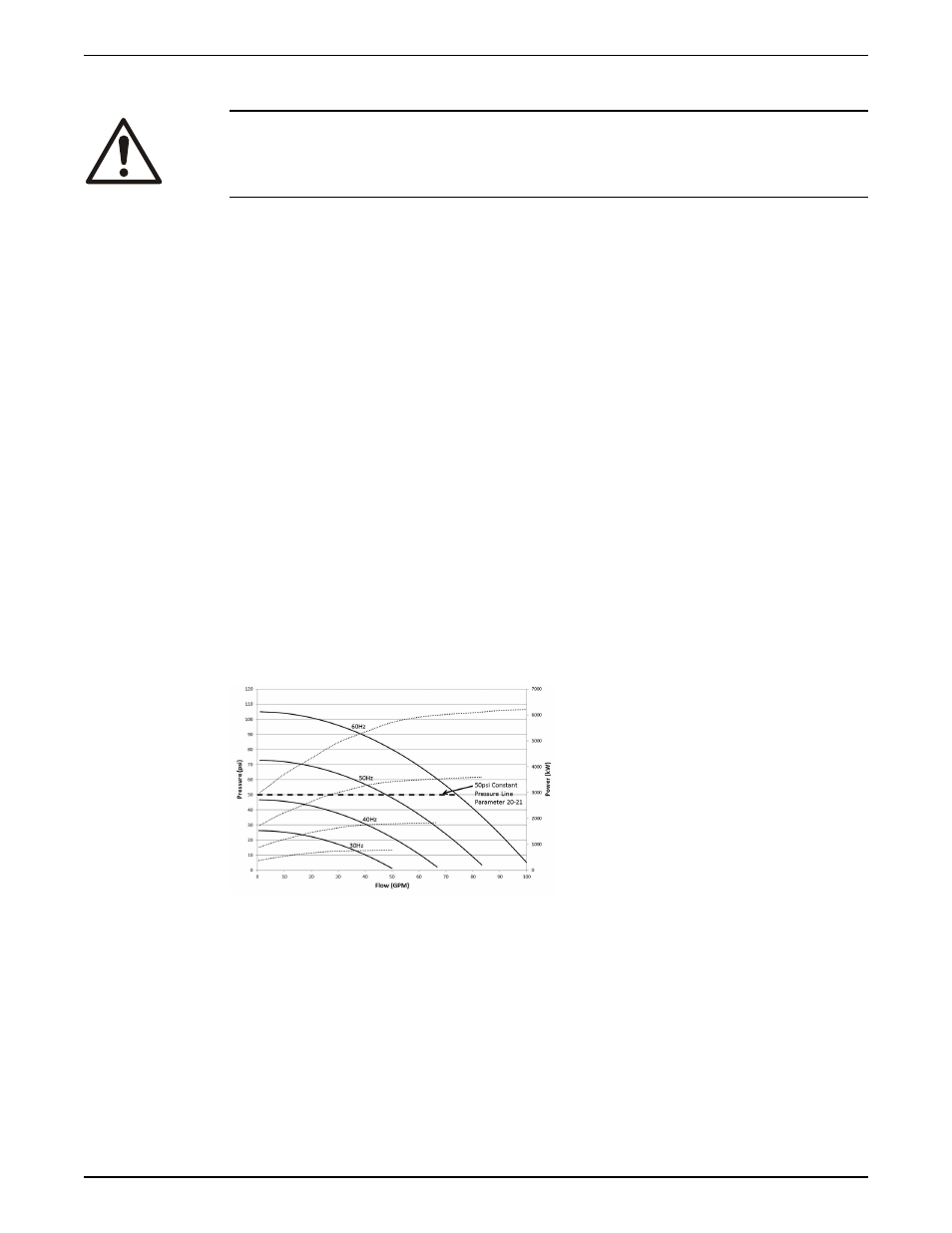

Figure 15: Pump performance and power curves

The solid lines in the diagram above show typical pump performance curves at various

speeds. The dotted lines show the pump power curve at various speeds. The dashed line

shows the setpoint of the process variable, in this case pressure. If a wired pressure

transducer was used, the transducer would provide feedback to the pressure control

loop. The pressure control loop would then calculate the speed required to maintain the

setpoint during various flow conditions. In the case of sensorless pressure control, the

drive calculates the pressure in the system based on the speed and power consumption

of the pump and sends this value to the pressure control loop. The pressure control loop

then calculates the speed command as with the wired transducer.

In either sensorless pressure or flow control mode the manipulated variable can be

monitored or displayed by accessing parameter 18-50 Sensorless Readout [Unit]. In

System Setup and Operation

Integrated Technologic

®

with Sensorless Control INSTRUCTION MANUAL

29