Model lm, lmn, 2 connection of piping to the pump, 3 drive – Xylem LMN User Manual

Page 48: 4 electric connection

Installation, Operating and Maintenance Instruction

Model LM, LMN

LM ger/fr/eng

Page 44

Revision 06

Article No 771073101

Issue 08/2013

The size of these insulating pads will vary,

depending on circumstances, and should

therefore be determined by an experienced

specialist.

5.2 Connection of Piping to the Pump

The pump must not be used as fixed point for

the piping. The permitted piping loads must not

be exceeded, refer to chapter 3.7.

5.2.1 Suction and discharge pipe

The pipes must be of a size and design that liquid

can flow freely into the pump and that the pump

functions without problems. Particular attention is

to be paid to ensuring that suction pipes are

airtight and that the NPSH values are observed.

Under suction lift condition lays the suction pipe in

the horizontal section towards the pump so that it

is slightly inclined upwards so that no air traps

occur. Do not install fittings or elbows right before

the suction nozzle.

If the suction supply is under vacuum and

entrained gas may be present in the liquid, it is

recommended that a vent line (min. diameter 25

mm) be considered upstream of the pump suction

with return to the suction supply, above the max

liquid level.

An additional flushed piping - discharge branch-

vent line - makes it easier to de-aerate the pump

before start-up (pic 3).

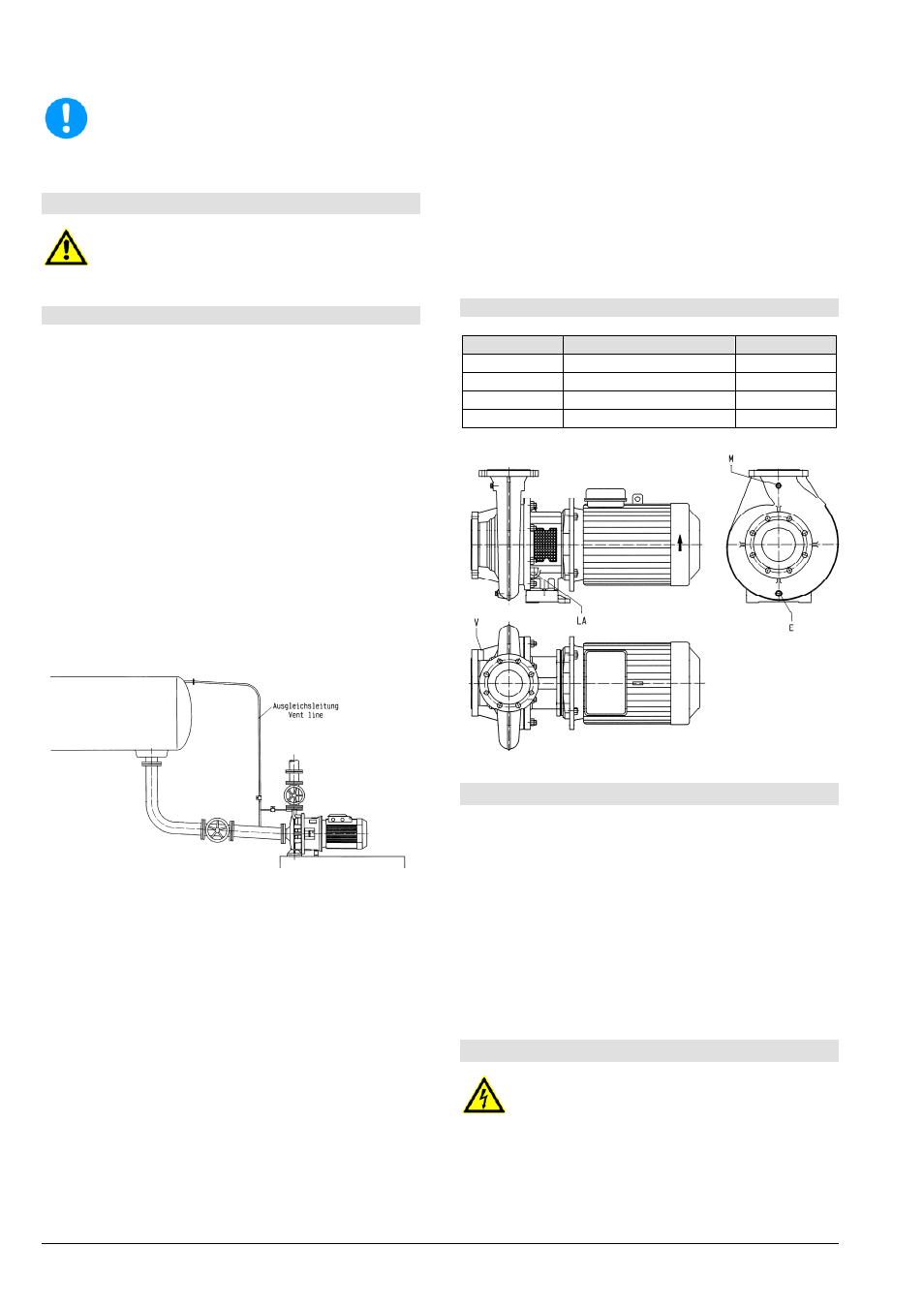

pic 3

When laying the pipes, make sure that the pump

is accessible for maintenance, installation and

disassembly.

Notice "Permitted Forces on Flanges" (chapter

3.7).

If expansion joints are used in the pipes, they

have to be supported in such a way that the pump

is not loaded unduly high because of the pressure

in the pipes.

Before connecting up to pump: remove protective

coverings from suction and discharge branches.

Before starting up, the pipe system, fittings and

equipment must be cleaned to remove weld

spatter, scale etc. Any pollutants are to be

completely removed from pump units that are

directly or indirectly connected to drinking water

systems before being installed and taken into use.

To protect the shaft sealing (especially mechanical

seals) against foreign impurities, it is

recommended that a sieve, 800 micron, is

installed in the suction / intake pipe when the

motor is being started up.

If the pipe system is tested with the pump

installed, do not exceed the maximum permitted

casing pressure of the pump and/or shaft sealing

(see data sheet).

When emptying the pipe after the pressure test,

make sure that the pump is treated properly

(danger of rust and problems when starting up).

5.2.2 Additional connections

The following additional connections are available:

Connection

Description

Dimension

E Pump

drain

R3/8"

LA leakage

R1/2"

M Pressure

gauge

R1/4"

V*) Vacuum

gauge*)

R1/4"

*) ... optional, drilled on request

5.3 Drive

The motor design of the pump is shown in the order

confirmation or on the motor name plate.

Note the Operating Instructions of the motor

manufacturer.

If in the process of repair a new motor is used, the

following has to be noticed:

The motor must comply with the requirements

stated in sheet 1130.1A608 (order from

manufacturer, on demand).

Clean motor end and motor flange of new motor

carefully (remove varnish).

5.4 Electric Connection

Electrical connection work may only be carried

out by an authorised professional. The rules

and regulations valid for electrical technology,

especially those concerned with safety

measures, must be observed. The regulations

of the national power supply companies

operating in that area must also be observed.