Model lm, lmn, Transport, handling, storage, Mounting / installation – Xylem LMN User Manual

Page 47: 1 transport, handling, 2 storage / conservation, 1 mounting of pump / unit

Installation, Operating and Maintenance Instruction

Model LM, LMN

LM ger/fr/eng

Page 43

Revision 06

Article No 771073101

Issue 08/2013

4. Transport, Handling, Storage

4.1 Transport, Handling

Check the pump / pump unit immediately upon

delivery / receipt of despatch for damage or

missing parts.

The pump / pump unit must be transported

carefully and by competent personnel. Avoid

serious impacts.

Keep the pump / pump unit in the same position in

which it was supplied from the factory. Take note

of the instructions on the packaging.

The suction and discharge side of the pump must

be closed with plugs during transport and storage.

Dispose of all packing materials in accordance

with local regulations.

Lifting devices (e.g. fork-lift truck, crane, crane

device, pulleys, sling ropes, etc.) must be

sufficiently strong and must only be used by

authorized persons.

The pump / pump unit may only be lifted by solid

points such as the casing, flanges or frame.

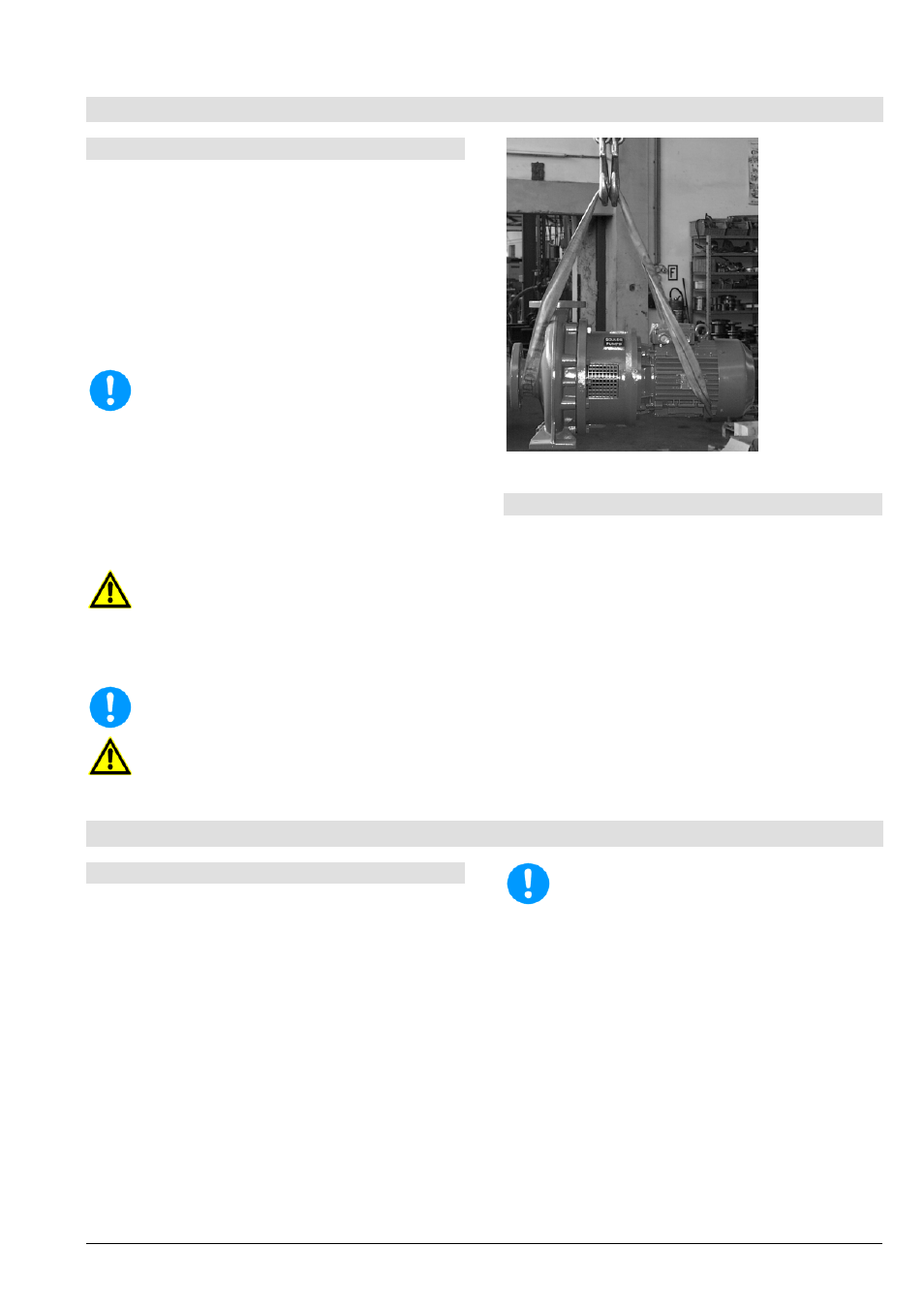

Picture 2 shows the correct method of carrying by

crane.

Do not stand underneath suspended loads.

Take note of the general regulations on

prevention of accidents.

The pump / pump unit must be secured against

tipping over and slipping until it has been fixed

in its final location.

Sling ropes must not be fixed to ends of shafts

or the ring loops of the motor.

Slipping out of the pump / unit of the transport

lifting device can cause damages to persons

and things.

pic 2

4.2 Storage / Conservation

Pumps or units, which are stored over a longer period

before start-up (max. 6 months), must be protected

from moisture, vibrations and dirt (e.g. by wrapping in

oil paper or plastic). Pumps must basically be stored in

a place where they are protected from the weather,

e.g. under dry cover. During this time, all suction and

discharge branches and all other intakes and outlets

must be closed with dummy flanges or plugs.

For longer periods of storage conservation

measurements at machined surfaces and packing with

moisture protection can be necessary!

5. Mounting / Installation

5.1 Mounting of Pump / Unit

The pumps must be bolted to a solid base (e.g.

concrete foundation, steel plate, steel bracket, etc.).

This base must withstand all loads occurring during

operation. The place, where the pump is mounted

must be prepared acc. to the dimensions of the

dimensional drawings. The concrete foundations

should have sufficient firmness acc. to DIN 1045 or

equal standard (min. BN 15), to ensure a secure,

functional mounting.

The concrete foundation must have set, before the

unit is erected. Its surface must be horizontal and

even. For the position and size of the pump feet and

the foundation screws refer to the dimensional

drawing.

Concrete expansion bolts, epoxy capsule anchor bolts

or anchor bolts grouted with the foundation (stone

screws), can be used for.

Sufficient space must be provided for

maintenance and repair work, especially for

replacing the drive motor or the complete pump

unit. The motor fan must be able to take in

enough cool air, and the intake grille must

therefore be at least 10 cm away from any wall,

etc.

When mounting the pump on the foundation it

must be adjusted at the discharge nozzle by

means of a spirit-level (at discharge nozzle). The

permitted deviation is 0,2 mm/m. Levelling shims

must be inserted next to the foundation anchors

and must lie plainly.

If vibrations are transmitted to the foundation from

adjoining components, it must be guarded through

adequate vibration damping paddings (vibrations

from outside can impair the bearing).

To prevent vibrations being transmitted to

adjoining components, the foundation should be

laid on a suitable insulating base.