System design, Typical constant pressure systems – Xylem IM043 AQUAVAR Variable Speed Pump Control User Manual

Page 6

5

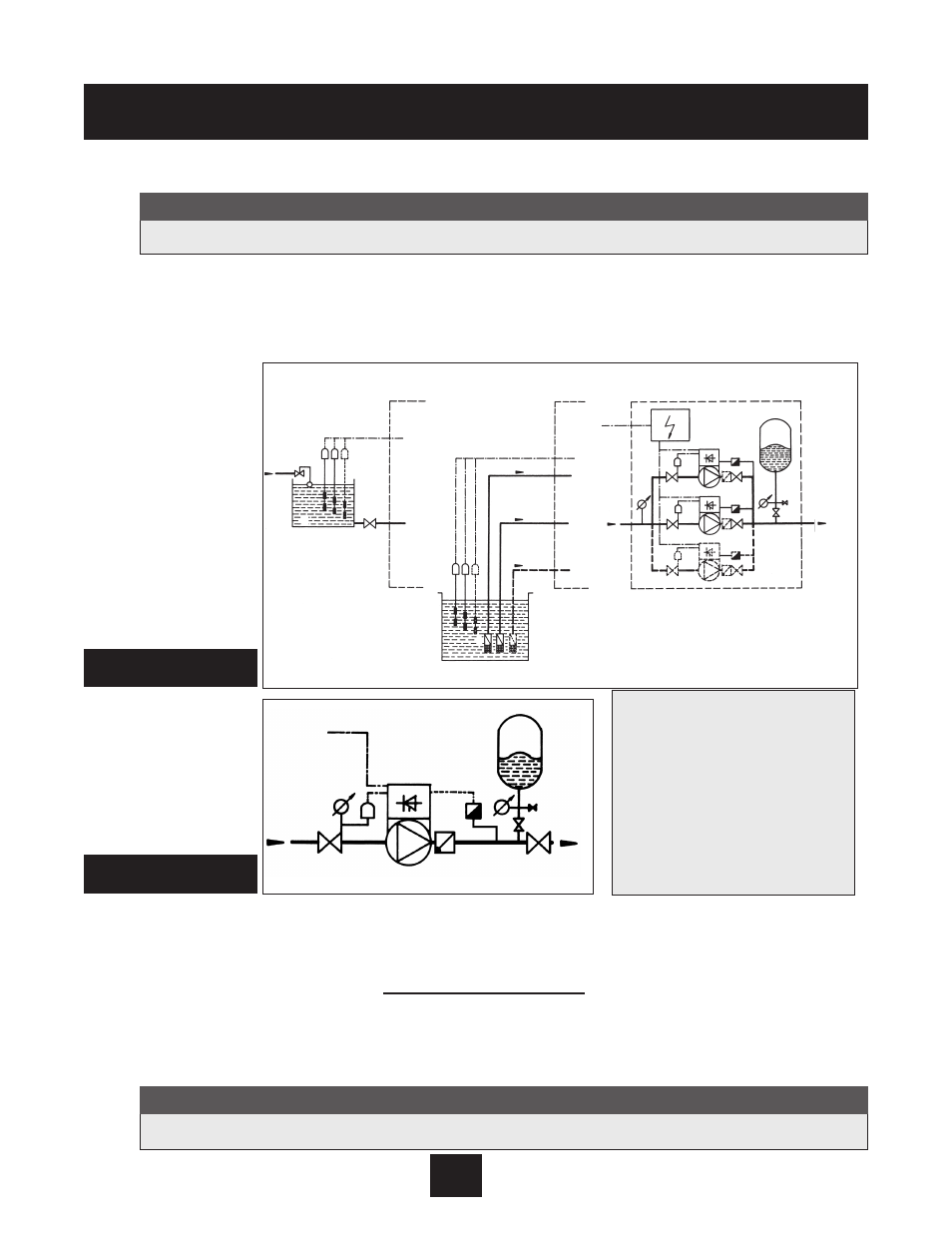

Typical Constant Pressure Systems

The following diagrams show typical single pump and multi-pump systems using the AQUAVAR con-

troller. Connection can be made directly to a water supply or water can be drawn from a supply tank

or well. In the case of supply tanks and wells, level switches, (item 10) can be used to shut down the

pumps when water is low. In the direct connection, a pressure switch on the suction side (item 8) can

be used.

A diaphragm pressure tank is used on the discharge side of the pump or pumps to maintain pres-

sure in the line when there is no demand. This will keep the pumps from continuing to run. With the

AQUAVAR controller control unit, it is not necessary to have a large tank for supply purposes. In select-

ing a tank, make sure it can withstand maximum system pressure. The tank should have a capacity of

about 10% of the maximum system flow rate in gpm. Pre-charge the tank to the following:

System Design

1 Pump with AQUAVAR controller

2 Diaphragm tank

3 Distribution panel

4 Gate valves

5 Check valves

6 Foot valves

7 Incoming pressure switch

8 Pressure gauges

9 Level switches

10 Supply tank

11 Pressure transmitter

Closed loop circulator systems may not require a pressure tank.

Note

Systems MUST be designed by qualified technicians only.

Note

PSI Set Pressure

15

30

45

60

75

90

105

120

135

150

PSI Tank Pre-charge

12

21

37

52

64

77

95

117

125

138

Diagram 2

Single Pump Layout

Diagram 1

Multiple Pump Layout

Indirect connection

via tank

Suction out or a well

Direct connection

9

10

9

6

8

7

4

3

7

4

7

4

1

1

1

11

5 4

11

5

4

11

5 4

2

8

8

4

7

1

5

4

8

11

2