Aquavar, Installation procedures, Electrical connections continued – Xylem IM043 AQUAVAR Variable Speed Pump Control User Manual

Page 18: U, v, w

17

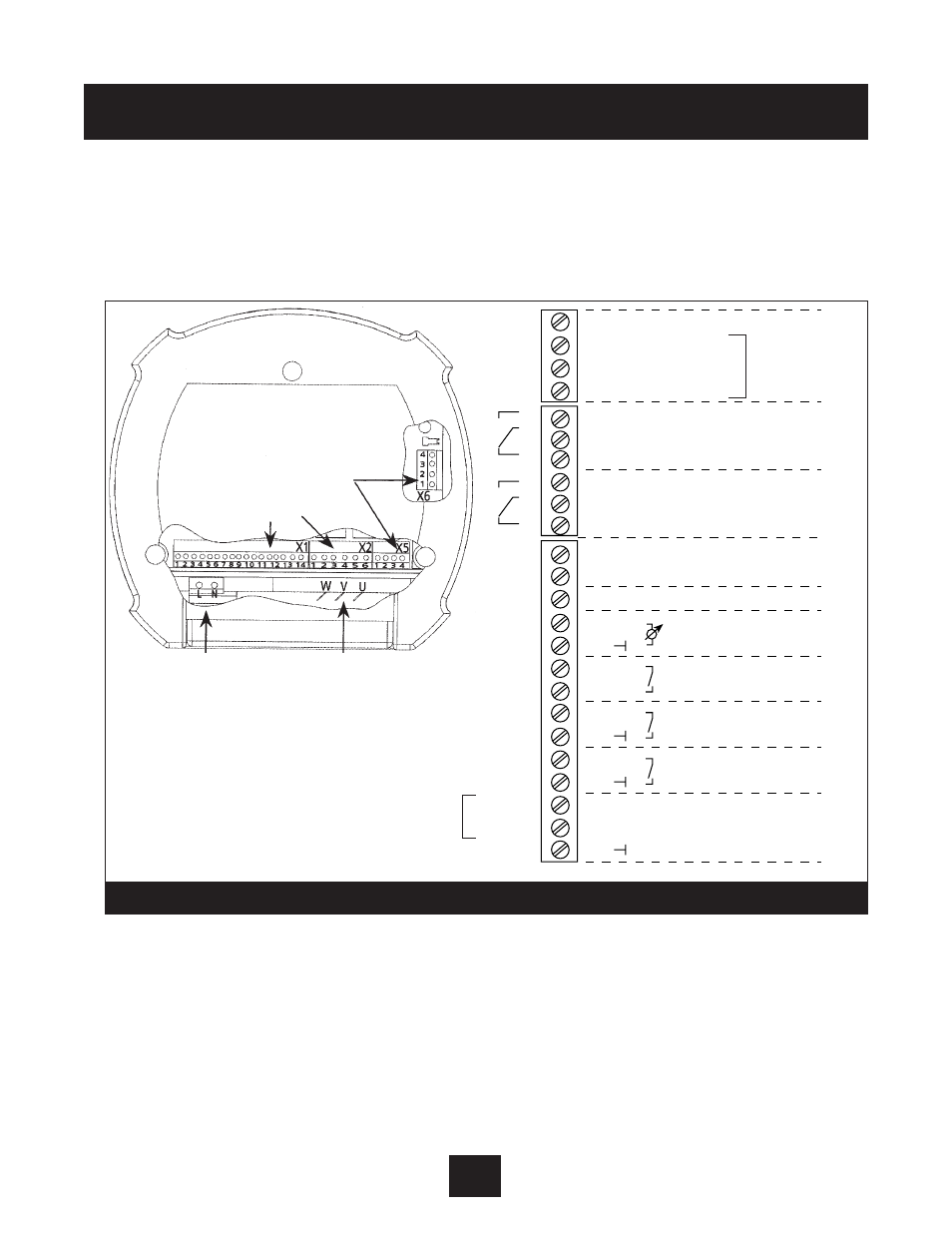

electrical Connections continued

10. Now select one of the ports in the AQUAVAR controller to route the trans-

ducer cable. Cut to length and connect to locations X1 #2 and #3 as shown in Diagram 8.

The brown wire is connected to X1 #3 and the white wire to X1 #2. Tighten strain relief.

11. Input Power Cable Installation

The main power cable is connected to the terminal block labeled L1, L2 (N) for the 230 volt

1phase input power units, and labeled L3, L2, and L1 for the 460 volt 3 phase input power

units; refer to Diagram 5.

12. Select one of the ports in the AQUAVAR controller to route the input power cable.

Installation Procedures

BROWN – 3

WHITE – 2

4

3

2

1

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

+ 5V

GND

SIO +

SIO -

15 V

IN

(4-20 mA)

RS-485

pump running signal

fault signal

Current Signal Input (4-20 mA)

Analog signal output (0-10V)

Motor thermo or PTC

low Water or jumper

external on or jumper

U

b

(max 100 mA)

actual value signal

shielding

X1

X2

Multi-

pump

Transducer

connection

Jump

Jump

X5

NO

CC

NC

NO

CC

NC

Digital Input

Voltage Signal Input (0-10Vor 2-10V)

AUBURN, NeW yORK 13021

•

PRESSURE?

•

AUTOSTART?

•

SAVE

•

START

•

STOP

or

(on) or

(off)

+

POWER

RUN

FAULT

I

D

S

S

�

S

�

�

�

S

�

�

�

�

�

�

AQUAVAR

TM

X2

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

X1

U

V W

L1

L2

SCh 60.05

MOTOR

MAIN POWER

13

14

X5

4

3

2

1

X4

4 3 2 1

PE

PE

RS485

AQUAVAR

®

RS485 Interface

Control Terminals

Power Supply

Motor Connection

1x230 VAC

3 Phase Out

L=L

1

, N=L

2

U, V, W

Diagram 8