GC EUROPE Fujivest Super User Manual

Page 46

46

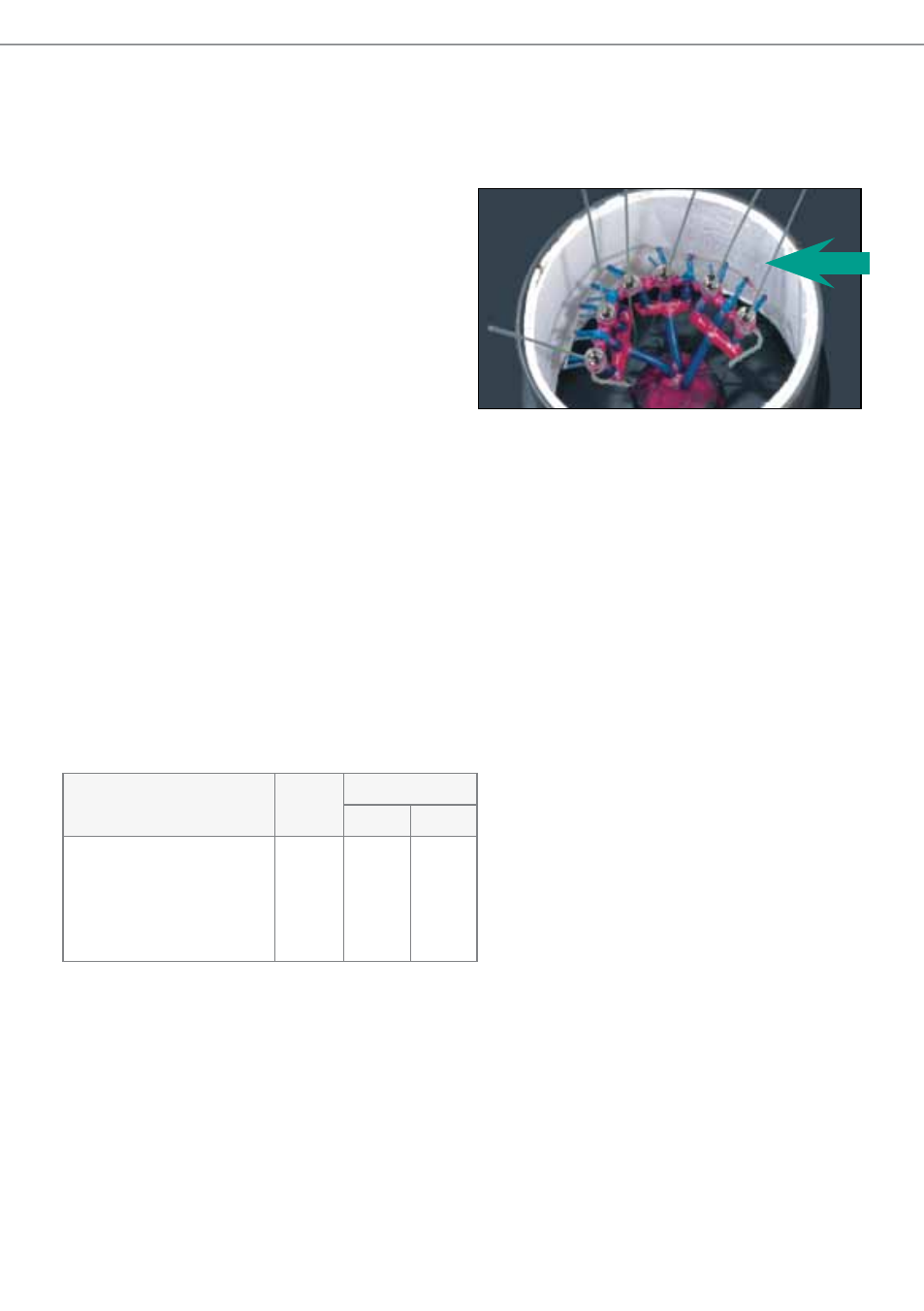

11.2 A thin 0.7-0.8 mm wax wire is put into all

abutments before investing. Immediately

after investing these wax wires are pulled

out. This pulling out creates a vacuum,

which avoids/eliminates air-bubbles in the

abutments.

11.3 Invest under low vibration.

12. Setting time

12.1 Leave to set for 20 min from start of mixing.

12.2 Scrape the top surface of the investment

ring with a sharp knife.

12.3 Put into a cold furnace, immediately after the

20 min. setting period and start the

heating-up cycle.

13. Setting time

13.1

Note:

- If more than 1 ring is placed in the furnace

at the same time, each holding time(phase)

should be extended by 10 min.

-

If vacuum pressure casting is being used raise

the end temperature by 50°C.

13.2 When pre-heating is done over night,

proceed with pt. 1 and 2. of the step heating

cycle (13.1) immediately after the 20 min

setting period. Shut off the furnace and

re-start from pt. 1 during the night. Leave

the casting ring in the furnace.

Step heating

Heat

rate

Time

x 6

x 9

1. Room temp. (23°C)

"

260°C

2. Holding time at 260°C

3. 260°C

"

580°C

4. Holding time at 580°C

5. 580°C

"

750°C Au-alloy

850°C Ceramic alloy

6. Holding time at end temp.

2°C/min

3°C/min

5°C/min

70 min

40 min

70 min

90 min

50 min

60 min