Heating up / burnout procedures – GC EUROPE Fujivest Super User Manual

Page 18

18

3

Heating up / Burnout procedures

3.1 Schedule in Instruction for Use

The majority of GC Europe investment materials can be used with either the quick or step heating

technique, however as each investment has its own heating schedule the corresponding ‘Instructions

for Use’ must be consulted. For example here is the heating schedule for GC Fujivest Premium.

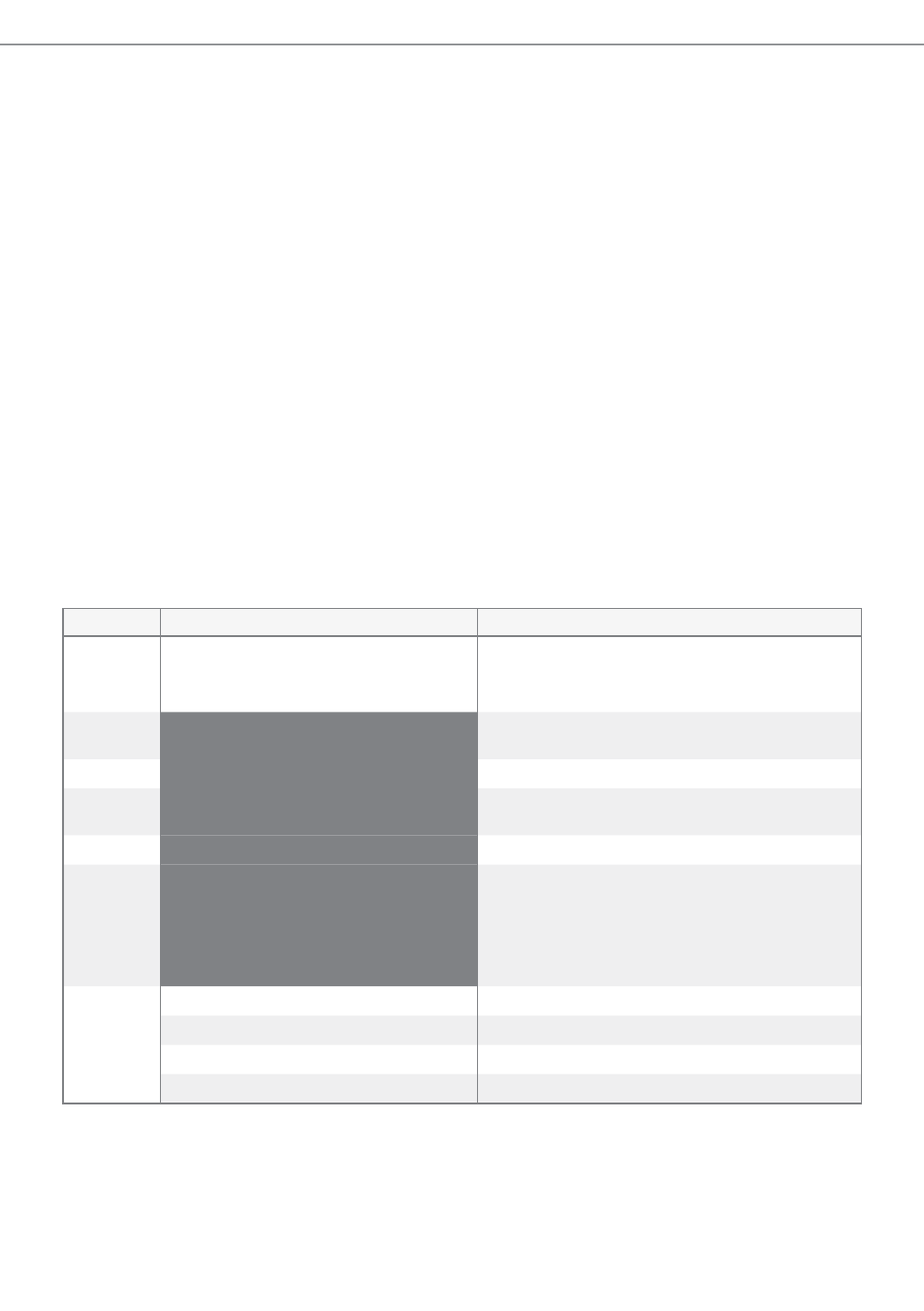

Quick heating

Conventional Step heating

Insertion

temperature

Pre-heated furnace at

700°-750°C/1290-1380°F for Au - alloys

800°-850°C/1470-1560°F for Ceramic alloys

900°C/1650°F for Non-precious alloys

Room temperature

Step 1

Room temperature (23°) to 260°C/500°F

Heat rate 3°C/37° F per min

Step 2

Holding time at 260°C/500°F 40-90 min

Step 3

Rise temperature from 260°C/500°F to 580°C/1076°F

Heat rate 6°C/43° F per min

Step 4

Holding time at 580°C/1076°F 20-50 min

Step 5

Rise temperature from 580°C/1076°F to 750°C/1380°F

for Au-Alloys

Rise temperature from 580°C/1076°F to

800-850°C/1470-1560°F for Ceramic Alloys

Rise temperature from 580°C/1076°F to 900°C/1650°F

for Non-precious Alloys

Heat rate 9°C/48°F per min

Holding time

X1 40 min at end temperature

X1 30 min at end temperature

X3 50 min at end temperature

X3 40 min at end temperature

X6 60 min at end temperature

X6 50 min at end temperature

X9 90 min at end temperature

X9 60 min at end temperature

- Due to aggressive burning out, do not open the furnace during heating-up. In case of vacuum

pressure casting, raise the end temperature by 50°C/122°F.

- When several investment rings are put into the furnace at the same time, prolong the heating period

by 10 min per investment ring.

- Best results are obtained by putting immediately into a preheated furnace after 20 min, i.e. the Quick

heating method.