25 focus edition from gc – GC EUROPE Fujivest Super User Manual

Page 25

25

Focus Edition from GC

5

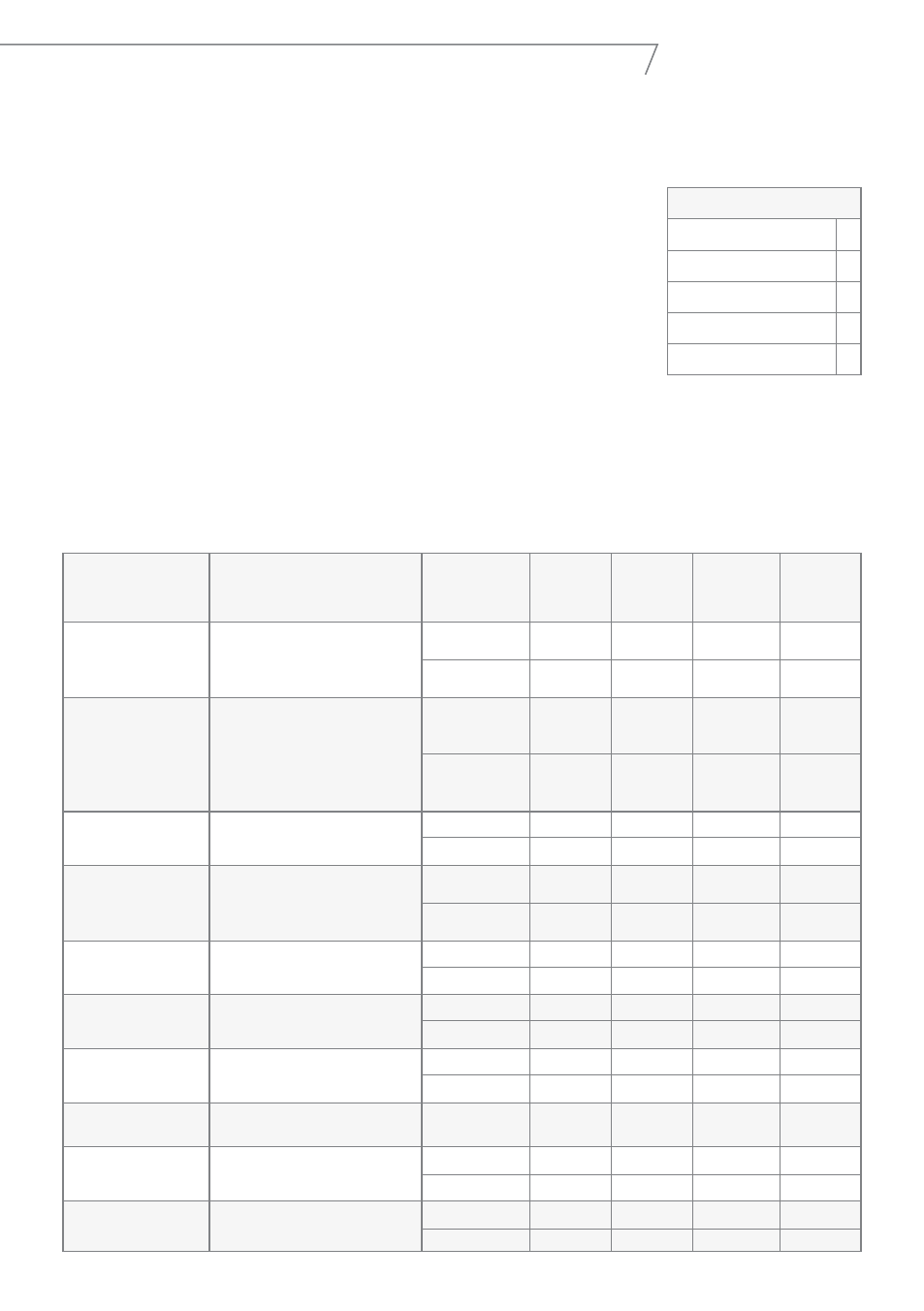

Effects of the main factors influencing the casting results

Factors influenced by

customers

Standard advise in IFU

Change

Effect on

expansion

level

Effect on

Fit

Effect on

Surface

of casting

objects

Effect on

mould

cracks/

defects

Powder Liquid ratio

Standard ratio :100 g powder /

22 ml distilled water

Higher

(=more powder)

#

#

$

&

Lower

(=more liquid)

~

–

~

–

#

&

Storage temperature

Store powder and liquid at normal

room temperature (23°C).Do not store

the powder above 35°C. If stored below

21°C, let powder and liquid adjust to

room temperature before use. Do not

store the liquid below 5°C,once frozen,

the liquid can not be used anymore

Higher

Uncontrolled

Uncontrolled

$

&

Lower

~

–

~

–

~

–

~

–

Working temperature

(=temperature of

powder and liquid)

Favourable powder & liquid

temperature is 21-23°C.

Higher

$

$

$

$

Lower

#

#

$

~

–

Dilution ratio

Dilution ratio as advised in IFU

per type of alloy

Higher

concentration

#

#

~

–

#

Lower

concentration

$

$

~

–

$

Setting time

(waiting time before

goining into furnace)

20 min

Longer

#

#

&

#

Shorter

$

$

$

#

Mixing speed of

vacuum mixer

320 - 420 Rpm

Higher

$

$

$

#

Lower

~

–

~

–

(

&

Mixing time with VAC

mixer

1 min with Vacuummixer

Longer

(

(

#

&

Shorter

~

–

~

–

(

&

Pre-Vacuum

Depends on type of investement,

consult IFU

> 15 sec

$

$

$

~

–

Ringtype

Depends on type of investement,

consult IFU

Ring

~

–

~

–

#

$

Ringless

&

&

'

#

Quality of water to

dilute

Use Distilled water

Distilled

~

–

~

–

~

–

~

–

Tap water

Uncontrolled

Uncontrolled

Uncontrolled

Uncontrolled

Key to symbols

No measurable difference

~

–

Higher

#

Lower

$

–

Slightly higher

&

Slightly lower

(