GC EUROPE Fujivest Super User Manual

Page 35

35

Focus Edition from GC

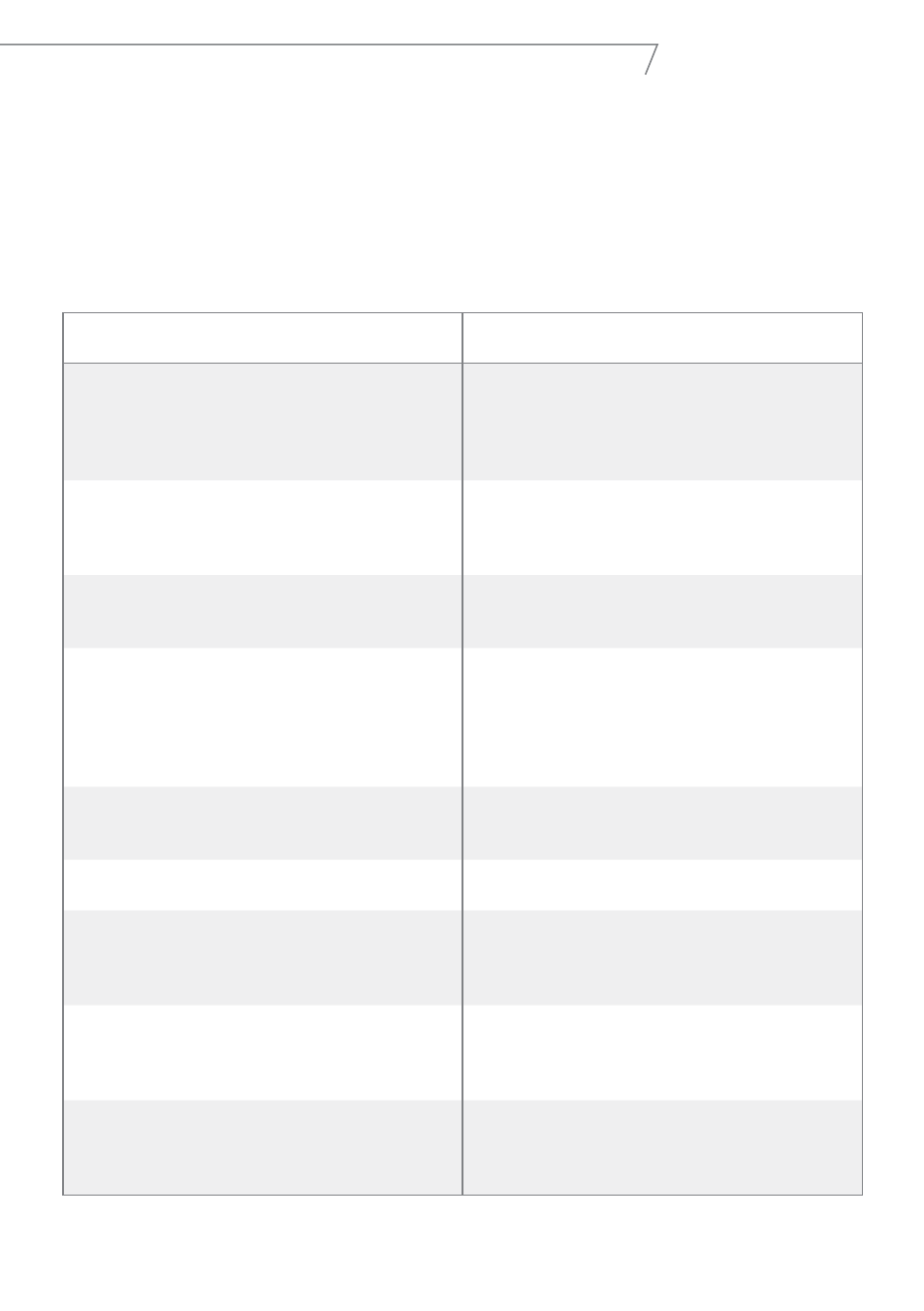

Cause

Remedy

- Use of a soft type of investment with ring

less technique and large amount of alloy

- Either use a more robust investment

material, the ring technique, calculate the

amount of alloy required according to the

wax weight

- Air bubble in set mould

- Avoid air entrapment by using a thin stream

when investing. Check the vacuum level of

the mixing devise

- Incorrect powder/liquid ratio causes a less

robust investment

- Check ratio in instructions for use the

accuracy of your measuring equipment

- The investment has been left too long after

investing

- If investment material is to be left for several

hours it is best to place it in a plastic bag or

other airtight sealed container to preserve its

humidity, prior to placing it in a burnout furnace

and heating according to the step procedure

- Crystals in liquid

- Keep investment liquid bottle tightly closed,

discard contaminated liquid

- Investing under pressure

- Not recommended

- Use of pre-heated furnace at high

temperature

- In case of a step heating schedule it is

advised that the initial temperature of the

furnace should be below 240°C

- Investment not thoroughly set

- Mix longer, use powder and liquid stored at

correct temperature (21-23°C) or allow to set

in warmer room

- Insufficient setting time

- Lengthen the time of bench setting before

mould is placed in oven. Check the

instructions for use