GC EUROPE Fujivest Super User Manual

Page 33

33

Focus Edition from GC

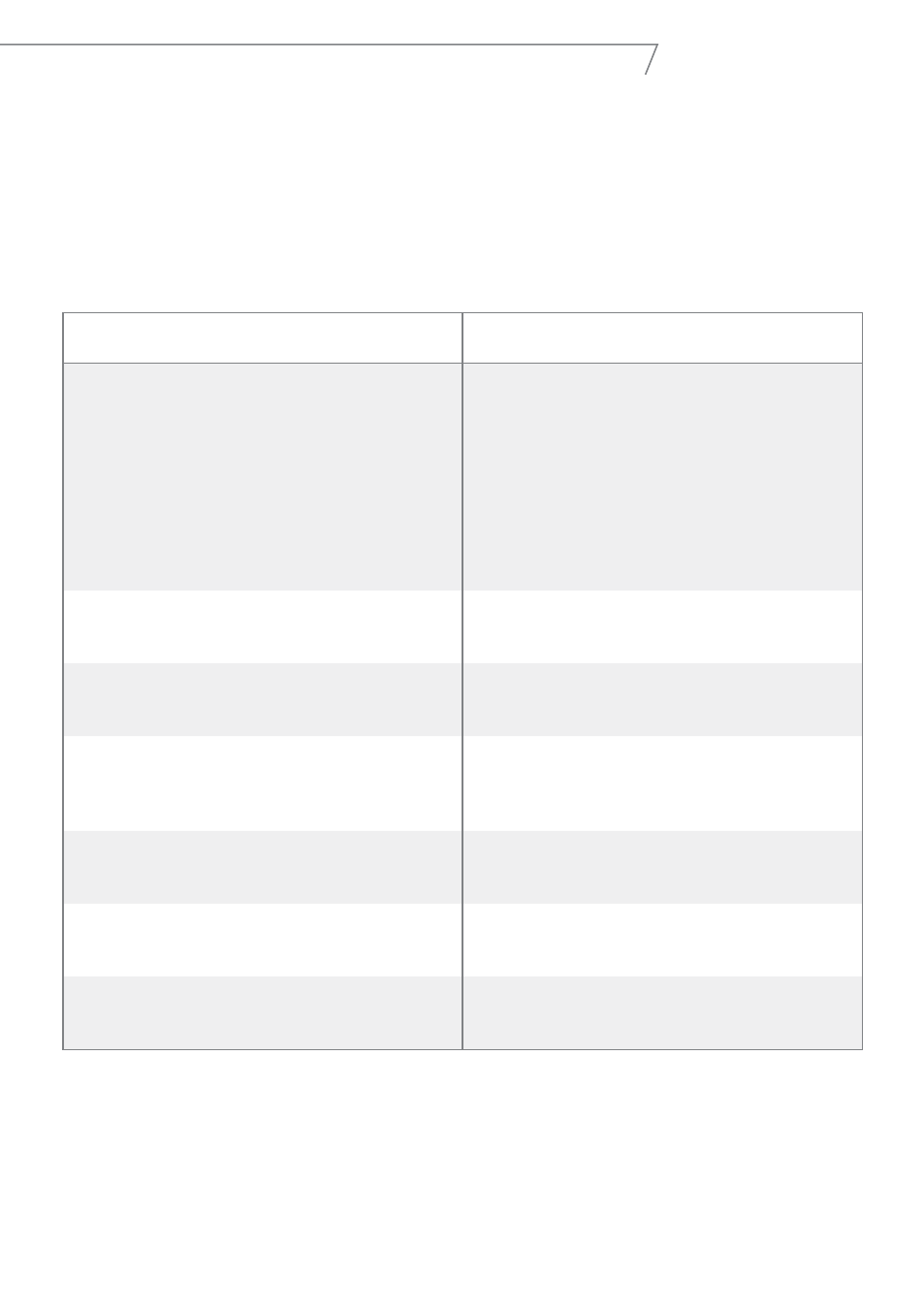

Cause

Remedy

- Entrapment of loose investment particles

- Ensure that the pattern and sprueing system

contain no sharp edges. Inspect the sprue

hole for sharp edges, trim them away and

thoroughly clean the area before placing

into the furnace.

Make sure that the junction between sprue

and wax pattern is smooth and correctly

connected. Do not re-cast alloy that has

been contaminated with investment particles

- Crystals in expansion liquid

- Keep investment liquid bottle tightly closed,

discard contaminated liquid

- Incorrect sprueing

- Review your pattern construction & sprueing

techniques

- Incomplete burnout

- Increase burnout time and/or burnout

temperature to ensure complete elimination

of the pattern material

- Absorption of gases into alloy melt during

the casting process

- Use at least 50% fresh alloy check your alloy

melting equipment and technique

- Use of carbon containing investment

material

- Use carbon-free investment material

- Water quality (contamination)

- Use distilled water to dilute the expansion

liquid