GC EUROPE Fujivest Super User Manual

Page 34

34

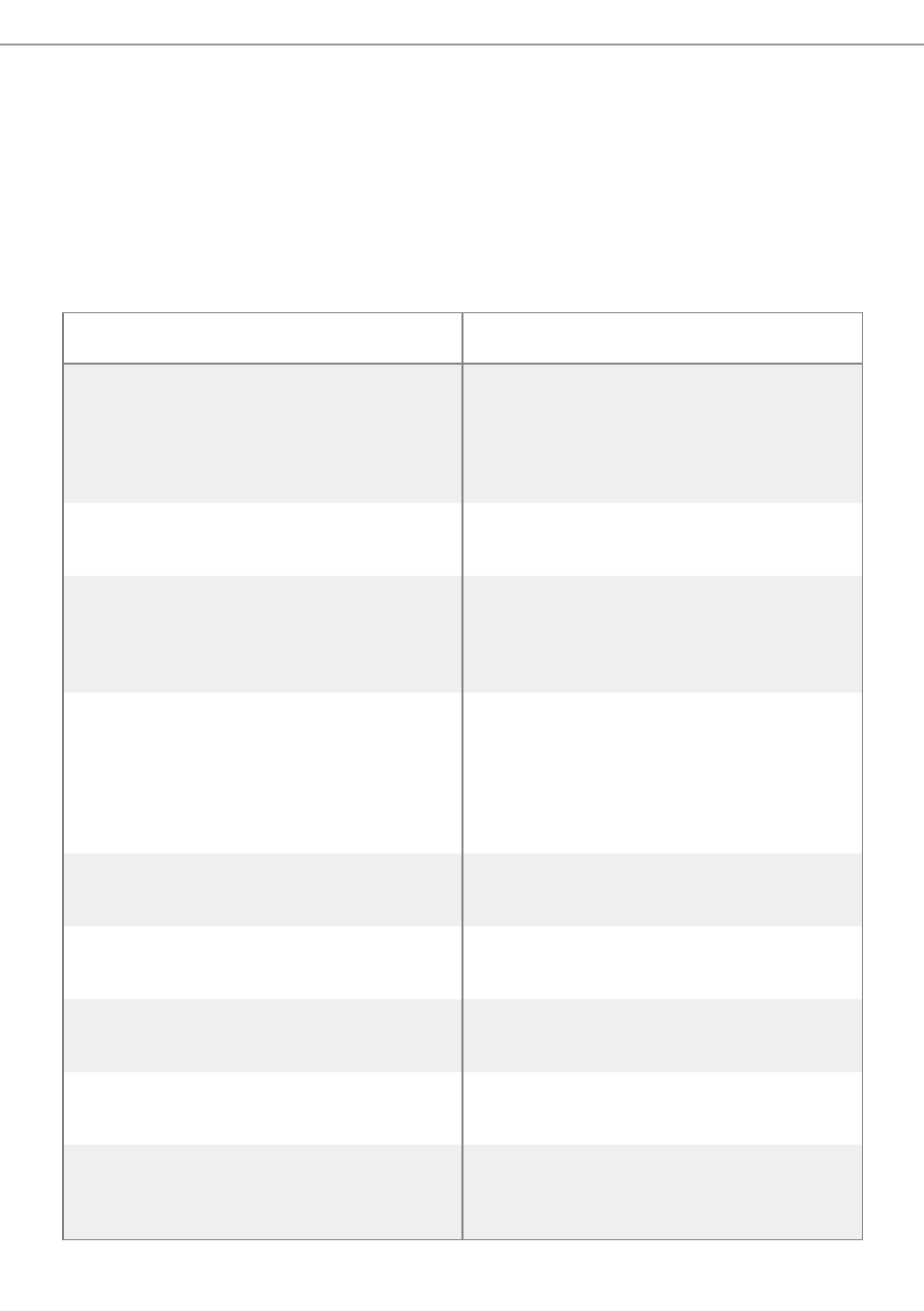

Cause

Remedy

- Too early and/or too fast burnout procedure

- Lengthen the time of bench setting before

investment mould is placed in furnace.

Consult the instruction for use for the correct

setting time, end-temperature and heating

up schedules

- Investment mould burnt out and allowed to

cool for too long prior to casting

- Cast as soon as possible after removing from

furnace

- Investing was continued when the

material had begun to set or the mould was

disturbed during setting

- Leave the mould to bench set completely

away from vibration, do not pour

investment when its consistency is not

correct or it begins to set

- Blockage of the main sprue hole during

early burnout by high melting pattern

materials, causing a build-up of pressure

within the mould

- Select pattern and sprue materials that melt

easily and burn out without difficulty; coat

plastic sprues with wax in order to allow wax

to drain away and plastic to expand for

optimal burn-out. It is preferable to use

hollow sprue systems

- Too many patterns

- Avoid placing too many patterns, use a

larger sized investment ring

- Patterns placed too close to ring wall or near

to the top of the ring

- Space patterns 5 mm from investment

mould wall and top of mould

- Mould is not porous enough for gases to

escape

- Scrape the top of the investment mould

before burnout

- Use of excessive pressure/force during

casting procedure

- Reduce pressure (number of turns/pressure)

- Invested with metal ring without liner

- It is advised to use the GC New Casting

Liner when using a metal ring (consult the

instruction for use)

5

Investment cracking

(fins on the castings, miscasting ….)