Inaccurate fit of casting objects – GC EUROPE Fujivest Super User Manual

Page 37

37

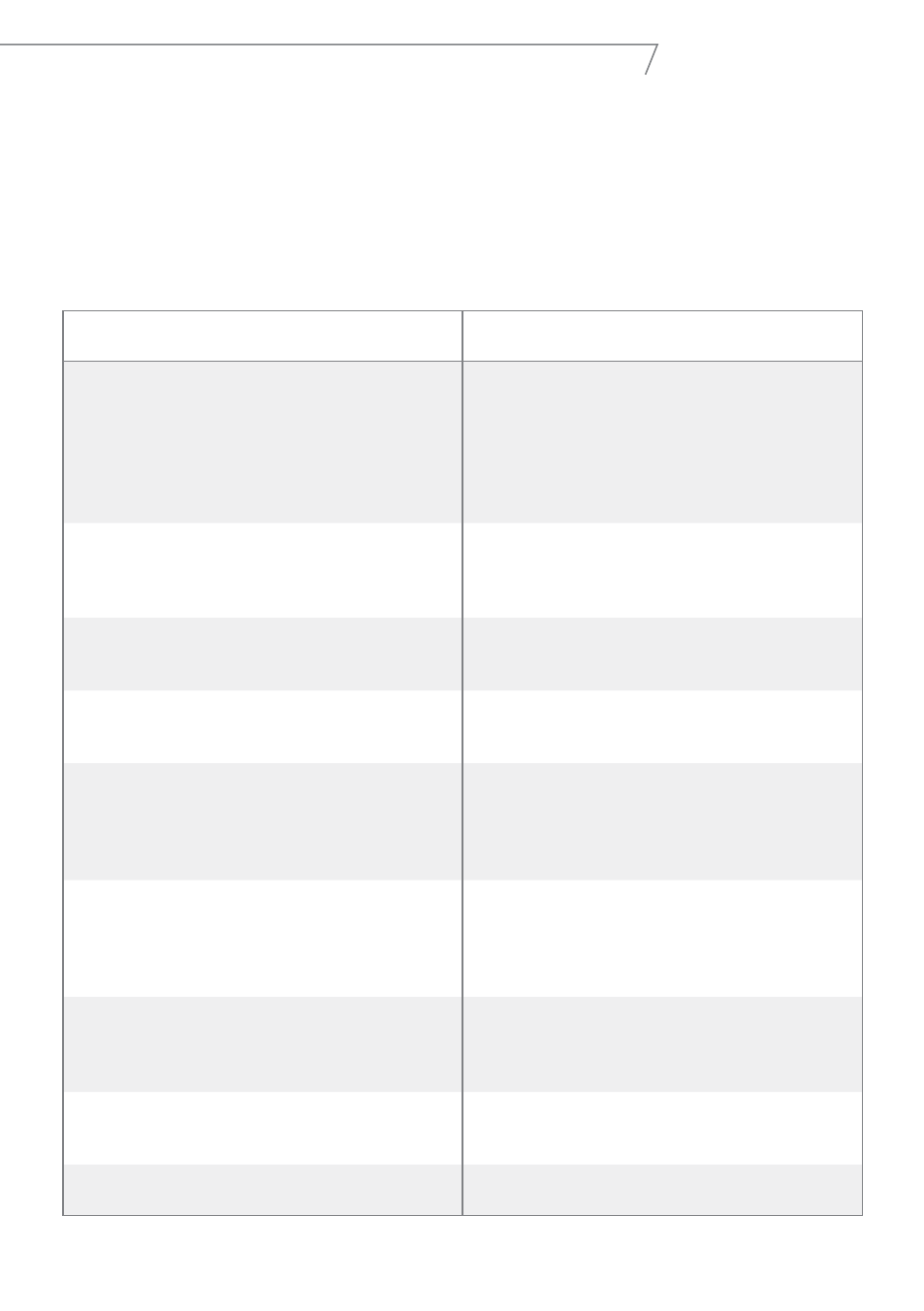

Focus Edition from GC

Cause

Remedy

- Incorrect liquid concentration

- To increase expansion, increase the liquid

concentration and to decrease expansion,

decrease liquid concentration (by diluting

with water). Do not dilute more than advised

, the use of too much water leads to

uncontrollable expansion level

- Incorrect powdrer/liquid ratio

- Check liquid/powder ratio in instructions

for use and the accuracy of your measuring

equipment

- Low temperature of mixture, low room

temperature

- Optimal working temperature of powder and

liquid is 21-23°C for most consistent results

- Incorrect liner thickness

- Use GC New Casting Liner to avoid the risk of

too little expansion

- Pattern material

- Pattern material with lower melting point

(e.g. inlay wax) can produces larger castings

whilst higher melting material (e.g. Pattern

Resin) can result in smaller castings

- Pattern deformation

- Handle wax pattern with extreme care,

wax-up under uniform temperature

conditions and allow the wax to rest to

create a stress free object

- Incorrect positioning/spruing of patterns in

the investment mould

- Ensure uniform thickness of investment

material around the objects to allow even

expansion. Review your sprueing technique

- Too fast cooling down of investment mould

- Allow a slow cooling down of investment

mould before devesting

- Improper mixing

- Check the Instructions for Use

7

Inaccurate fit of casting objects