Incomplete castings & rounded cervical edges – GC EUROPE Fujivest Super User Manual

Page 36

36

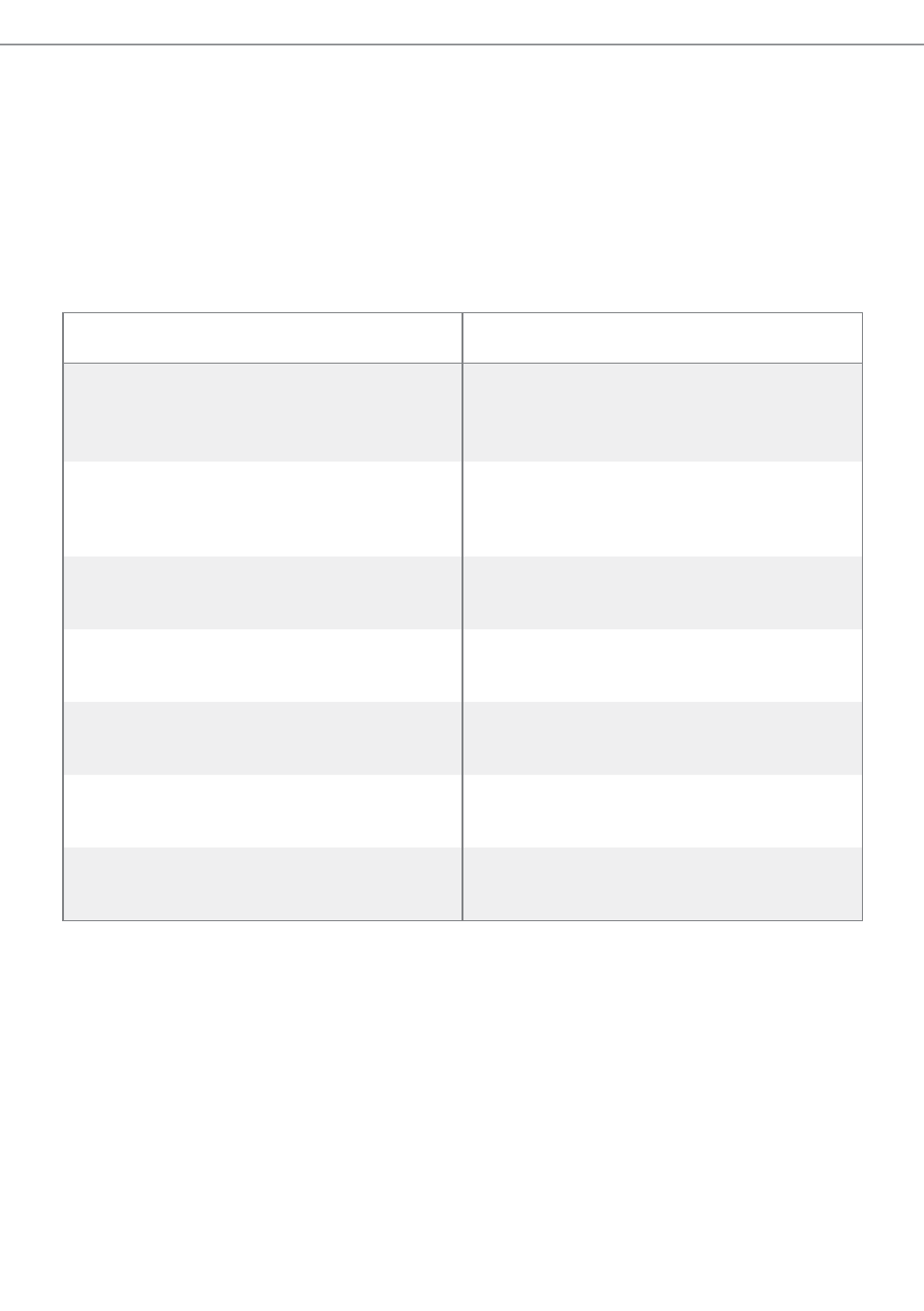

Cause

Remedy

- Incomplete elimination of pattern materials

- Heat soak longer at the recommended

temperature, ensure that the furnace is

correctly vented and calibrated

- Insufficient heating of the alloy/melt too

cold

- Increase casting temperature of alloy,

preheat the crucible, check the alloy

manufacturer’s data

- Investment mould too cold during casting

- Transfer investment mould to casting

machine and cast at once

- Casting machine operated with insufficient

pressure or too few turns

- Increase casting pressure; use more turns

- Misalignment of crucible and sprue hole

- Position investment mould with sprue hole

aligned with crucible

- Insufficient amount of alloy by weight

- Calculate the correct amount based upon

the wax weight

- Patterns improperly sprued ,Wax-up too

thin, wrong position of casting objects

- Review the pattern & sprueing system

6

Incomplete castings & rounded cervical edges