Surface mount information, Pick and place area, Lead free soldering – GE Industrial Solutions QW010-015-020 Series User Manual

Page 18: Pb-free reflow profile

Tyco Electronics Power Systems

18

Data Sheet

August 22, 2006

36 Vdc to 75 Vdc Input; 1.2 Vdc to 5.0 Vdc Output; 10 A to 20 A

QW010/015/020 Series Power Modules: dc-dc Converters;

Through-Hole Lead-Free Soldering Infor-

mation

The RoHS-compliant through-hole products use the SAC

(Sn/Ag/Cu) Pb-free solder and RoHS-compliant components.

They are designed to be processed through single or dual

wave soldering machines. The pins have an RoHS-compli-

ant finish that is compatible with both Pb and Pb-free wave

soldering processes. A maximum preheat rate of 3°C/s is

suggested. The wave preheat process should be such that

the temperature of the power module board is kept below

210°C. For Pb solder, the recommended pot temperature is

260°C, while the Pb-free solder pot is 270°C max. Not all

RoHS-compliant through-hole products can be processed

with paste-through-hole Pb or Pb-free reflow process. If addi-

tional information is needed, please consult with your Tyco

Electronics Power System representative for more details.

Surface Mount Information

Pick and Place Area

Although the module weight is minimized by using open-

frame construction, the modules have a relatively large mass

compared to conventional surface-mount components. To

optimize the pick-and-place process, automated vacuum

equipment variables such as nozzle size, tip style, vacuum

pressure, and placement speed should be considered. Sur-

face-mount versions of this family have a flat surface which

serves as a pick-and-place location for automated vacuum

equipment. The module’s pick-and-place location is identified

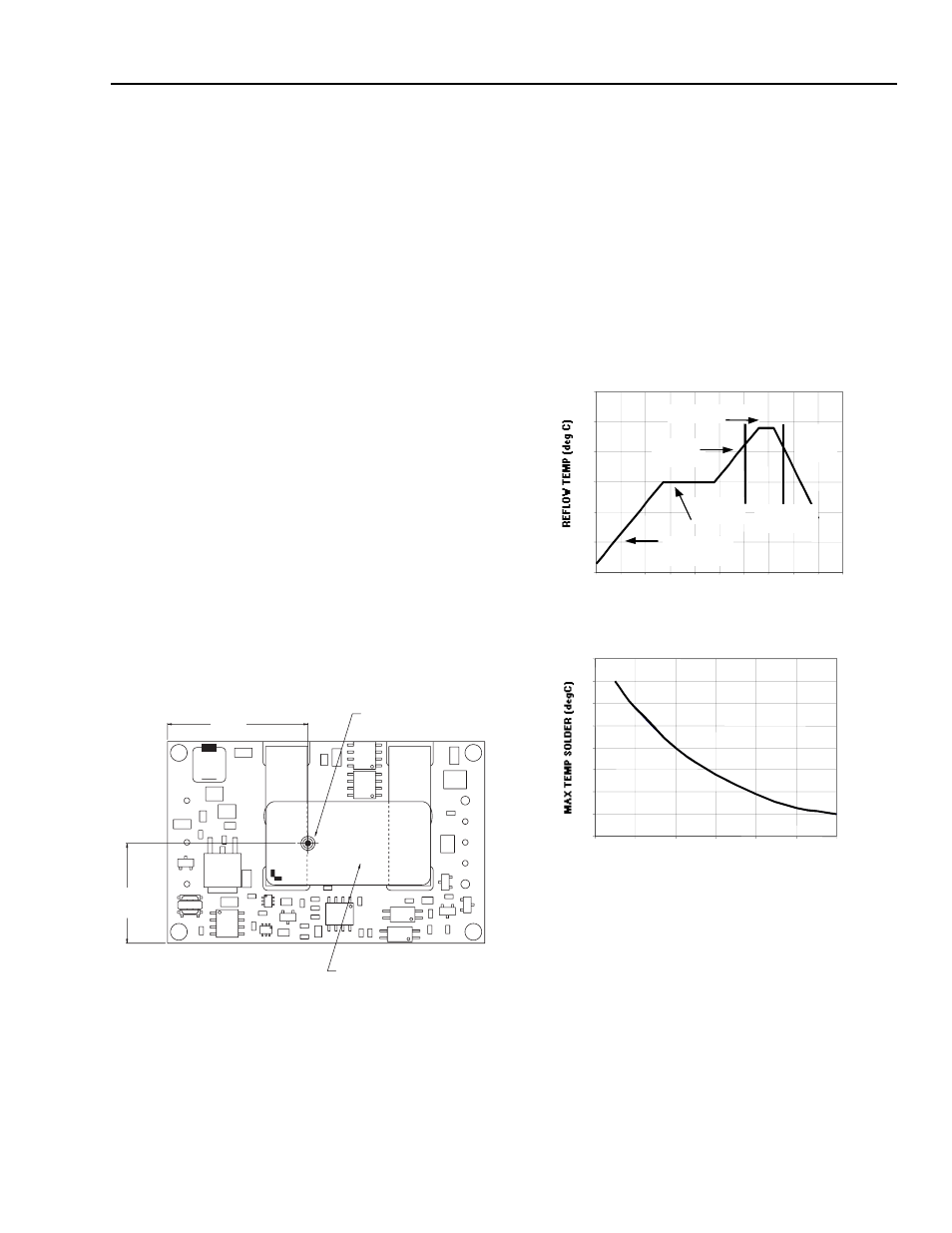

in Figure 56.

Figure 50. Pick and Place Location.

Reflow Soldering Information

The QW series of power modules is available for either

Through-Hole (TH) or Surface Mount (SMT) soldering.

These power modules are large mass, low thermal resistance

devices and typically heat up slower than other SMT compo-

nents. It is recommended that the customer review data

sheets in order to customize the solder reflow profile for each

application board assembly.

The following instructions must be observed when SMT sol-

dering these units. Failure to observe these instructions may

result in the failure of or cause damage to the modules, and

can adversely affect long-term reliability.

Typically, the eutectic solder melts at 183

o

C, wets the land,

and subsequently wicks the device connection. Sufficient

time must be allowed to fuse the plating on the connection to

ensure a reliable solder joint. There are several types of

SMT reflow technologies currently used in the industry.

These surface mount power modules can be reliably sol-

dered using natural forced convection, IR (radiant infrared),

or a combination of convection/IR.

Figure 51. Recommended Reflow profile.

Figure 52. Time Limit curve above 205

0

C.

Lead Free Soldering

The -Z version SMT modules of the QW series are lead-free

(Pb-free) and RoHS compliant and are compatible in a Pb-

free soldering process. Failure to observe the instructions

below may result in the failure of or cause damage to the

modules and can adversely affect long-term reliability.

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. C (Moisture/

Reflow Sensitivity Classification for Nonhermetic Solid State

Surface Mount Devices) for both Pb-free solder profiles and

MSL classification procedures. This standard provides a rec-

ommended forced-air-convection reflow profile based on the

volume and thickness of the package (table 4-2). The sug-

gested Pb-free solder paste is Sn/Ag/Cu (SAC). The recom-

mended linear reflow profile using Sn/Ag/Cu solder is shown

in Figure. 59.

Pick and Place Target

Symbol on Label

Product Label

PIN 1

PIN 2

PIN 3

PIN 8

PIN 7

PIN 6

P

IN 5

PIN 4

25.654

(1.01)

18.288

(0.72)

0

50

100

150

200

250

300

REFLOW TIME (S)

Preheat zone

max 4

o

Cs

-1

Soak zone

30-240s

Heat zone

max 4

o

Cs

-1

Peak Temp 235

o

C

Cooling

zone

1-4

o

Cs

-1

T

lim

above

205

o

C

200

205

210

215

220

225

230

235

240

0

10

20

30

40

50

60

TIME (S)