Product description, Step 1 – unpack and inspect – GE Industrial Solutions Record Plus TDM, NEMA 1, 3R, 12: FC100 User Manual

Page 2

concernant les possibles modifications a apporter

a l'equipement.

Product Description

These instructions describe the installation

procedures for the rotary handle FNRH operating

mechanism accessory on

Record Plus™

circuit

breakers, as illustrated in Figure 1.

The complete kits are available in the following

catalog number variants:

• FCNRN provides the necessary parts for shallow

door mount of the handle on the breaker

mechanism through the enclosure door, with a

box depth of 5.0 inches (127 mm), as shown in

Figure 1a. Maintain the dimension “H” [4.69

inches (119.0 MM)] as shown in Figure 13.

• FCNRT is for mounting the handle and

operator in enclosures with variable depth, as

shown in Figure 1b. Maintain the dimension

“H” [Min 6.84 inches (173.7 mm) and Max 15

inches (381.0 mm)] as shown in Figure 14.

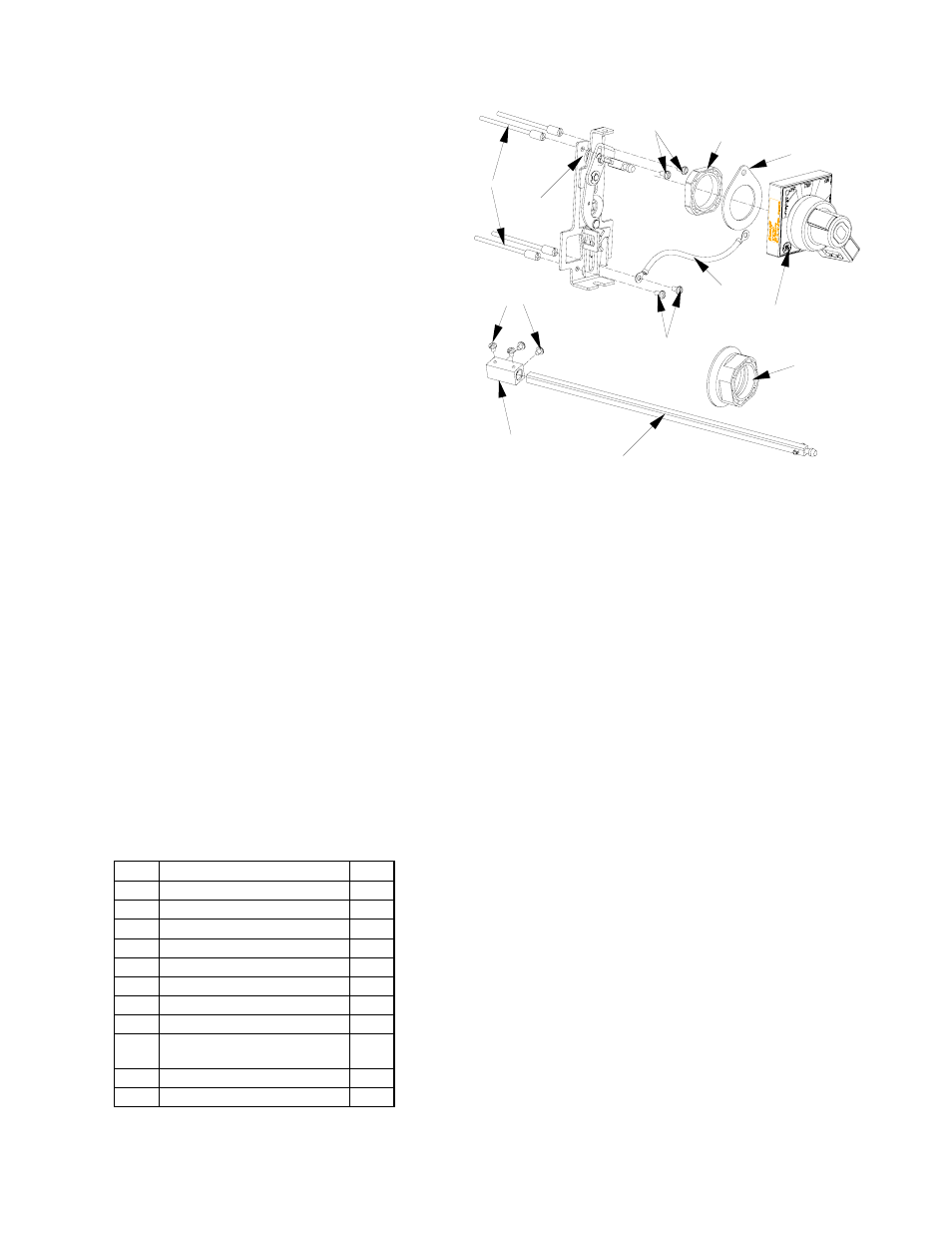

Figure 2. Parts supplied in the FNRH rotary handle kits.

[7]

[2]

[1]

[4]

[3]

[5]

[6]

[8]

[9]

[10]

[4]

[11]

In addition, the individual kit parts are available as

follows:

Step 2 – Install the Breaker and

Handle Operating Mechanism

• FCNRM1 consists of the operating mechanism

for shallow door mount of the handle to the

breaker.

1.

Move the breaker handle to the OFF position.

2.

Mount the breaker to the enclosure with the # 8-

32

• FCNRM3 consists of the operating mechanism

for extended shaft door mount of the handle.

x 2.81" screws [1], as illustrated in Figure 3.

Tighten the screws to 16 - 20 in-lb.

Complete the

installation of the circuit breaker according to

installation instructions DEH40463.

• FNRH is the handle assembly only.

Step 1 – Unpack and Inspect

3.

Place the base-crank assembly [2] on the breaker,

as illustrated in Figure 4. Insert four #8-32 x

0.312" screws [4] through the mounting holes in

the base and into the heads of the breaker

mounting screws [1], with the grounding wire [3]

attached to one of the screws. Tighten the screws

to 16 - 20 in-lb. Secure the other end of the

grounding wire to a suitable ground location.

Unpack the rotary handle operating mechanism kit

and inspect the parts for any shipping damage.

Verify that all parts are supplied, as listed in Table 1.

The parts are illustrated in Figure 2.

Note that the numbers in brackets in the following

figures and installation instructions refer to the item

numbers in

4.

For kit FCNRT variable-depth mounting only:

a.

Measure the distance from the breaker-

mounting surface to the rotary handle-

mounting surface, H, as shown in Figures 8

& 14.

Item Description

Qty.

1

Screw, #8-32 x 2.81"

4

2 Base-crank

assembly

1

b.

Cut the extension shaft [9] to the length

“L” given by

L = H – 120.5 mm (4.74 inch), as illustrated

in Figure 5.

3 Grounding

wire

1

4

Screw, #8-32 x 0.312"

4

5 Nut,

plastic

1

6

Rotary handle assembly

1

c.

Insert the shaft [9] upto 14 mm (0.55 inch)

into the coupler [8] and secure it with two

#8-32 X 0.312” screws [7], as illustrated in

Figure 6. Tighten the screws to 16 - 20 in-lb.

7

Screw, #8-32 x 0.312"

4

8 Coupler

1

9 Extension

shaft

assembly

1

d. Place the shaft [9] assembled with coupler

[8] on to the crank of the base-crank

assembly [2] and secure with two #8-32

10 Funnel,

plastic

1

11 Gasket

1

x

0.312" screws [7], as illustrated in Figure 7.

Tighten the screws to 16 - 20 in-lb.

Table 1. List of parts included in the handle operator kits.