12v austin microlynx, 5a: non-isolated dc-dc power modules, Data sheet – GE Industrial Solutions 12V Austin MicroLynx 5A User Manual

Page 10: Test configurations, Design considerations, Input filtering, Figure 24. output ripple and noise test setup, The austin microlynx

GE

Data Sheet

12V Austin MicroLynx

TM

5A: Non-Isolated DC-DC Power Modules

10Vdc –14Vdc input; 0.75Vdc to 5.5Vdc output; 5A Output Current

May 6, 2013

©2013 General Electric Company. All rights reserved.

Page 10

Test Configurations

TO OSCILLOSCOPE

CURRENT PROBE

L

TEST

1μH

B

A

TTE

R

Y

C

S

1000μF

Electrolytic

E.S.R.<0.1

Ω

@ 20°C 100kHz

2x100μF

Tantalum

V

IN

(+)

COM

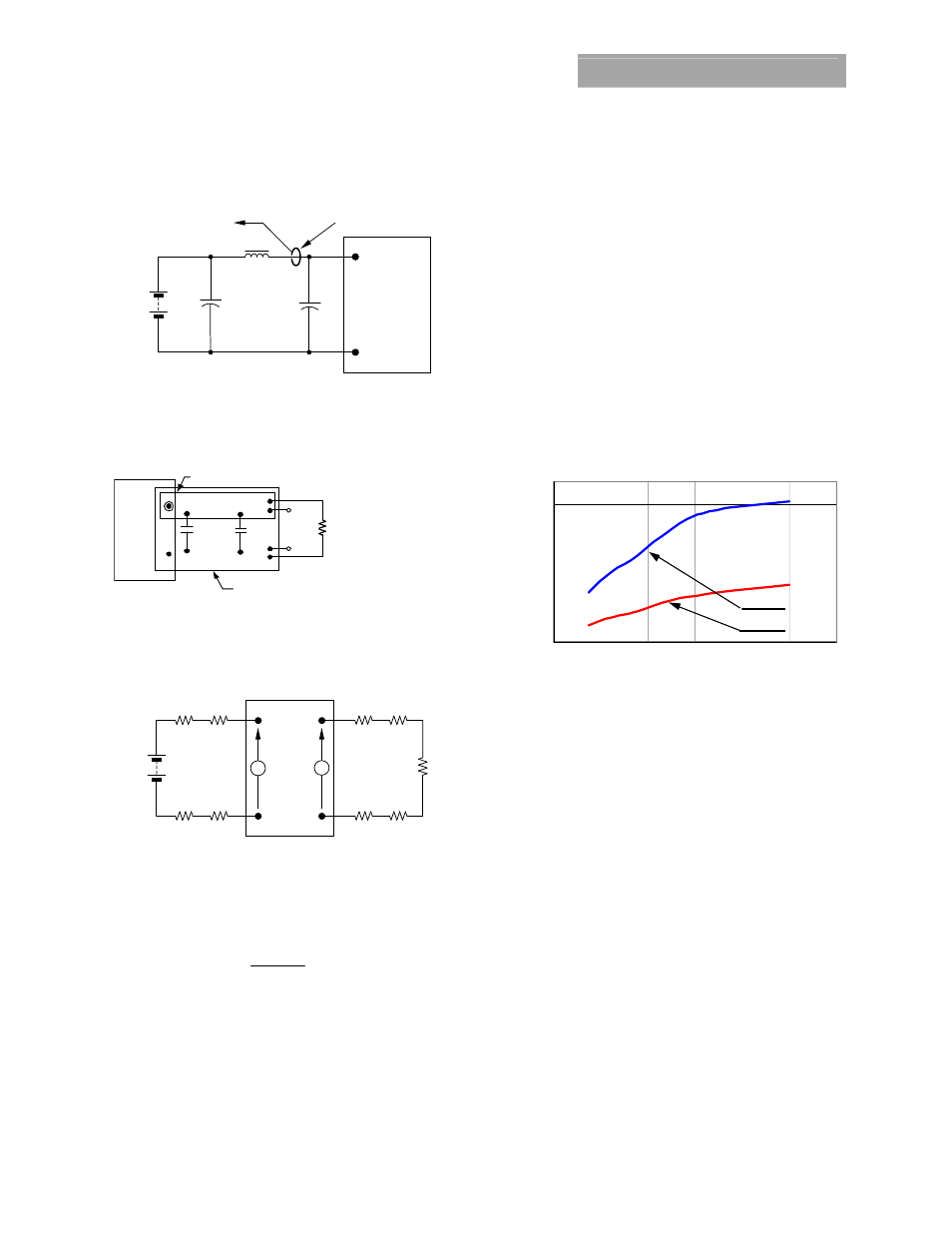

NOTE: Measure input reflected ripple current with a simulated

source inductance (L

TEST

) of 1μH. Capacitor C

S

offsets

possible battery impedance. Measure current as shown

above.

C

IN

Figure 23. Input Reflected Ripple Current Test Setup.

NOTE: All voltage measurements to be taken at the module

terminals, as shown above. If sockets are used then

Kelvin connections are required at the module terminals

to avoid measurement errors due to socket contact

resistance.

V

O

(+)

COM

1uF

.

RESISTIVE

LOAD

SCOPE

COPPER STRIP

GROUND PLANE

10uF

Figure 24. Output Ripple and Noise Test Setup.

V

O

COM

V

IN

(+)

COM

R

LOAD

R

contact

R

distribution

R

contact

R

distribution

R

contact

R

contact

R

distribution

R

distribution

V

IN

V

O

NOTE: All voltage measurements to be taken at the module

terminals, as shown above. If sockets are used then

Kelvin connections are required at the module terminals

to avoid measurement errors due to socket contact

resistance.

Figure 25. Output Voltage and Efficiency Test Setup.

η =

V

O

. I

O

V

IN

. I

IN

x

100

%

Efficiency

Design Considerations

Input Filtering

The Austin MicroLynx

TM

12V SMT module should be connected

to a low-impedance source. A highly inductive source can

affect the stability of the module. An input capacitance must

be placed directly adjacent to the input pin of the module, to

minimize input ripple voltage and ensure module stability.

In a typical application, 2x47 µF low-ESR tantalum capacitors

(AVX part #: TPSE476M025R0100, 47µF 25V 100 mΩ ESR

tantalum capacitor) will be sufficient to provide adequate ripple

voltage at the input of the module. To minimize ripple voltage

at the input, low ESR ceramic capacitors are recommended at

the input of the module. Figure 26 shows input ripple voltage

(mVp-p) for various outputs with 2x47 µF tantalum capacitors

and with 2x 22 µF ceramic capacitor (TDK part #:

C4532X5R1C226M) at full load.

Input Rippl

e Vol

tag

e

(m

Vp-

p)

0

50

100

150

200

250

300

350

0

1

2

3

4

5

6

Ceramic

Tantalum

Output

Voltage

(Vdc)

Figure 26. Input ripple voltage for various output with 2x47

µF tantalum capacitors and with 2x22 µF ceramic capacitors

at the input (80% of Io,max).