Applications above 250 v, C – wire terminal connections – GE Industrial Solutions Record Plus FG600 with SMR1 or SMR2 Trip Unit User Manual

Page 4

4

Applications Above 250 V

Because of safety considerations, a backplate must be attached

to the back of an FG breaker used in applications greater than

250 V. The backplate catalog number is listed in Table 6.

Table 6. Backplate used with applications above 250 V.

Mounting

Use Figure 4 as a reference to drill and tap all mounting holes

and make any necessary front panel escutcheon cut outs.

Mount the breaker using the appropriate breaker hardware kit,

listed in Table 7. Which includes four screws and lock washers.

Tighten the mounting screws to 20 lb-in.

Catalog

Number

Application Kit

Description

FGMSK1

Mounting plate with

tapped holes

Four #10-32 x 33/4

screws and lock

washers

FGMSK2

Mounting plate with

clearance holes

Four #10-32 x 41/4

screws, nuts, and lock

washers

Table 7. Breaker mounting kits.

Table 8. Lug catalog numbers and specifications

C – Wire Terminal Connections

NOTE: When using aluminum wire, use a joint compound

recommended by the wire manufacturer.

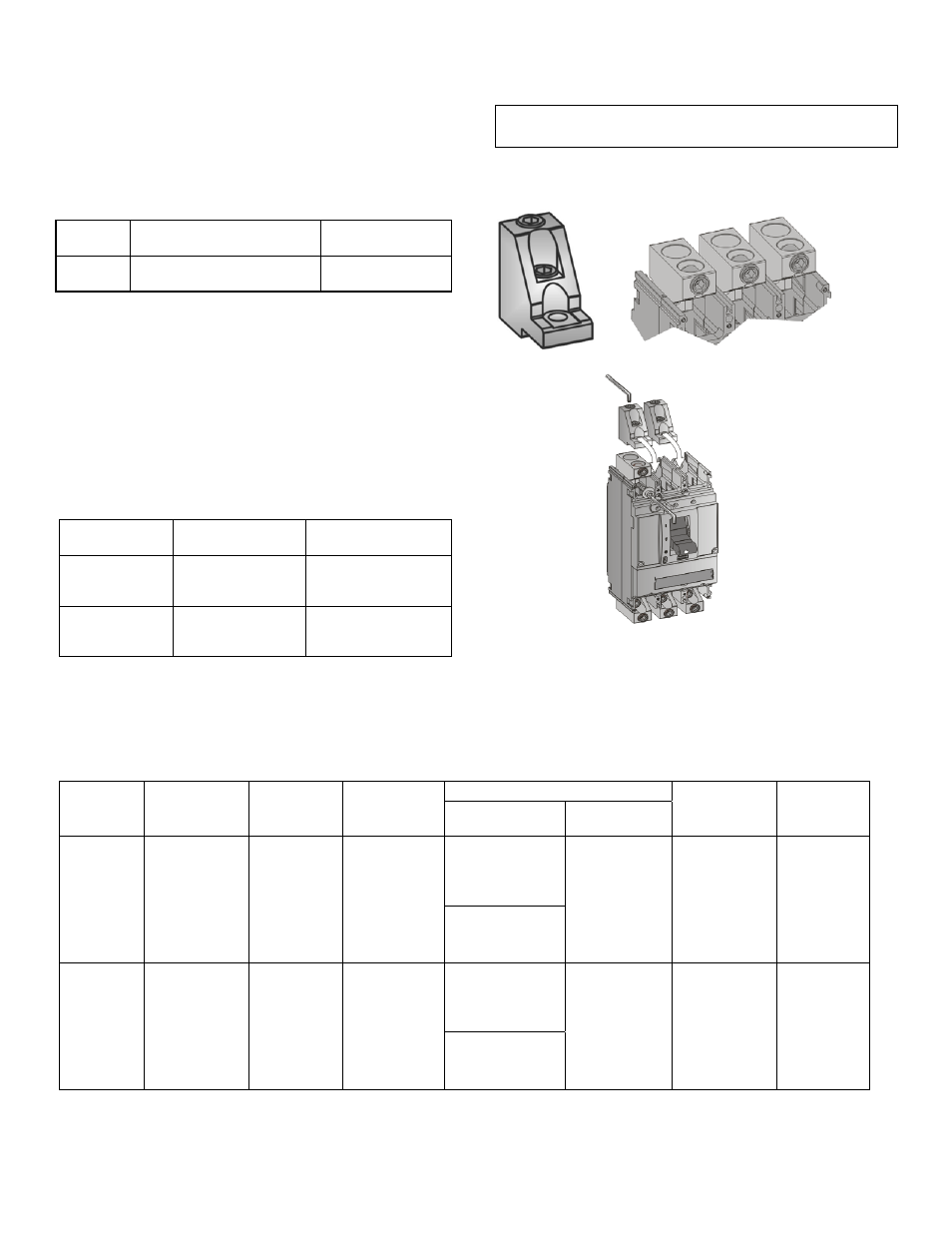

The lugs available for making wire connections to the breaker

are illustrated in Figure 3 and listed in Table 8.

Figure 3. Record Plus lug.

Catalog

Number

Application

Installation

Instructions

FGJB

Backplate for use with

applications above 250V

DEH40309

Catalog

Number

Wire Range

Dimension des

files

Wire Type

Location

Emplacement

Torque/Couple

Strip Length

Lug Material

Wire-Lug

Lug-Strap

FCALK218H

Top Hole

#8–400 kcmil

#6–500 kcmil

Bottom Hole

#2/0–600 kcmil

Copper

Aluminum

Copper or

Aluminum

2 Pole

(2 lugs)

#8–#4 AWG

AL/CU

275 in-lbs

200 in-lb

23 N-m

Top 7/8 in.

Bottom 15/8 in.

Tin-plated

aluminum

#3 AWG–600

kcmil AL/CU

375 in-lbs

FCALK318H

Top Hole

#8–400 kcmil

#6–500 kcmil

Bottom Hole

#2/0–600 kcmil

Copper

Aluminum

Copper or

Aluminum

3 Pole

(3 lugs)

#8–#4 AWG

AL/CU

275in-lbs

200 in-lb

23 N-m

Top 7/8 in.

Bottom 15/8 in.

Tin-plated

aluminum

#3 AWG–600

kcmil AL/CU

375 in-lbs