Section 5—operation, 1—general, 2—close spring charging – GE Industrial Solutions Power-Vac ML-20 Mechanism User Manual

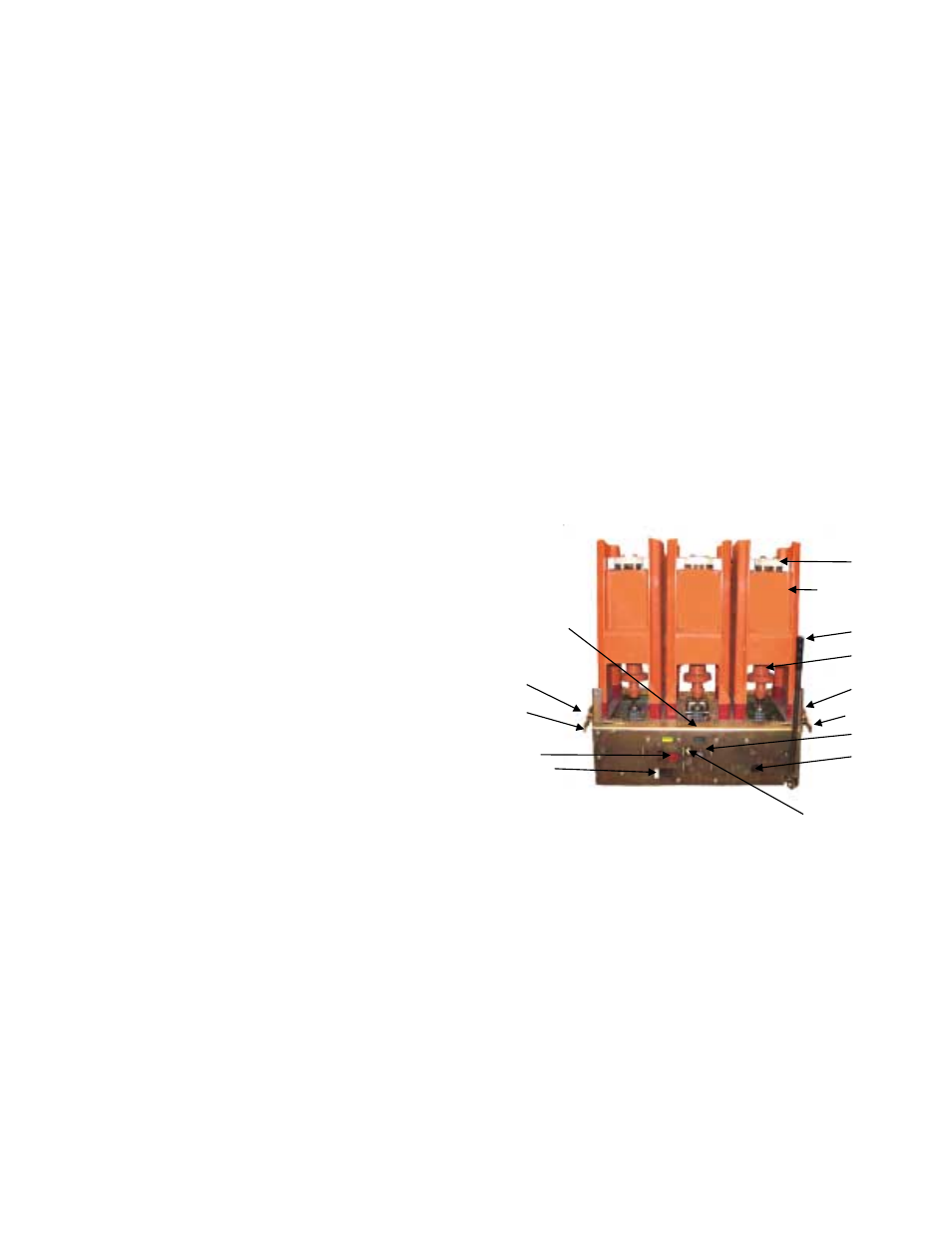

Page 8: Figure 3 front view of powervac, Breaker without front cover, 3—closing operation (refer to figure 15)

8

SECTION 5—Operation

5.1—General

The PowerVac

®

vacuum circuit breaker uses sealed vacuum

power interrupters to establish and interrupt a primary circuit.

Primary connections to the associated metalclad switchgear

are made by horizontal bars and disconnect fingers, electrically

and mechanically connected to the vacuum interrupters.

Molded interrupter supports, one per phase on a three-phase

circuit breaker, provide mountings for the primary bars,

interrupters, current transfer fingers, and heat dissipation fins

(where used). The operating mechanism provides direct

motion at each phase location in order to move the lower

contact of the vacuum interrupters from an open position to a

spring-loaded closed position and then back to the open

position on command.

The ML-20 mechanism (Figure 15) is of the stored-energy

type and uses a gearmotor to charge a closing spring. During

a closing operation, the energy stored in the closing spring is

used to close the vacuum interrupter contacts, compress the

wipe springs which load the contacts, charge the opening

spring, and overcome bearing and other friction forces, The

energy then stored in the wipe springs and opening spring will

open the contacts during an opening operation.

Closing and opening operations are controlled electrically by

the metalclad switchgear or remote relaying. Mechanical

control is provided by manual close and trip buttons on the

circuit breaker. The closing spring may be manually charged,

and a method for slow-closing the primary contacts is

available. The mechanism will operate at the ac or dc voltage

indicated on the circuit breaker nameplate.

5.2—Close Spring Charging

Figure 15 shows a front view of the ML-20 in a schematic

form. The primary contacts are open and the closing spring is

charged. The closing spring charging system consists of a

closing spring (1, view B) mounted on the left side of the

breaker and the electrical charging system mounted on the

right side of the breaker. Both components are fastened to

the cam shaft (2, view B). A manual charging system (3, view

A) is provided so that the mechanism can be slow closed and

the closing spring can be charged without electrical control

power.

Spring charging is accomplished electrically by a rotating

eccentric on the output shaft of the gear motor driving pivoted

charging arms (4, view C) which oscillate about the centerline

of a ratchet wheel (5, view C). A driving pawl (6, view C),

mounted within the charging arms, oscillates with the

charging arms. Starting from its rear-most position, as the

charging arms rotate forward, a spring forces engagement of

the driving pawl with a tooth of the ratchet wheel. The ratchet

wheel is advanced by the rotating charging arms and pawl

assembly. Advancement of one tooth spacing is provided for

each oscillation of the system. The ratchet motion is restricted

to one direction by a spring-loaded holding pawl that prevents

the ratchet wheel from going backwards as the charging arms

oscillate back to pick up the next tooth. Thirteen complete

cycles of the charging arms are needed for a full charge of the

closing spring. The efficient, compact gear motor

accomplishes this action in about three seconds. When the

charging cycle is complete, the ratchet wheel is positioned so

that three missing teeth adjacent to the driving pawl and any

motor overspin will not drive the ratchet wheel, thus

preventing damage to the system.

When the spring is completely charged, the assembly is

retained in that position by the close latch, until it is desired

to close the circuit breaker.

The closing coil cannot be electrically energized unless the

closing spring is completely charged. This action is prevented

by the 52/CHG switch in the closing circuit.

The manual charging system (3, view A) works directly on the

cam shaft where a one-way clutch (7, view A), driven by a

manual handle, provides rotation of the ratchet wheel. Manual

pumping of the handle advances the ratchet wheel and the

holding pawl prevents counter-rotation while the handle is

returning for another stroke. Approximately eight complete

strokes of the manual handle are required for one complete

spring-charging operation. When the spring charge indicator

(9, Figure 3) shows “CHARGED”, MANUAL CHARGING MUST

BE DISCONTINUED TO AVOID MECHANISM DAMAGE.

Figure 3 Front view of PowerVac

®

breaker

without front cover

1. Upper interrupt connection 8. Counter

2. Interrupter support

9. Spring charge indication

3. Operating rod

10. Manual charge lever

4. Racking arm

11. Manual close button

5. Compartment track rollers 12. Test position handle for

6. Manual trip button

secondary disconnects

7. Open/Close indicator

13. Closing spring gag access

5.3—Closing Operation

(refer to Figure 15)

By either energizing the close solenoid or depressing the

manual close button, the close latch (8, view C) is rotated,

releasing the closing spring (1, view B). This action releases

the energy in the closing spring and transmits it to the closing

cam (9, view D) and closing roller (10, view D) and causes

1

12

2

3

4

5

10

11

8

13

9

6

9

7

5

4