Data sheet, Surface mount information – GE Industrial Solutions EHHD006A0B Hammerhead Series User Manual

Page 12

GE

Data Sheet

EHHD006A0B Hammerhead Series; DC-DC Converter Power Modules

18-75Vdc Input; 12Vdc, 6.0A, 72W Output

July 12, 2013

©2012 General Electric Company. All rights reserved.

Page 12

Surface Mount Information

(continued)

MAX TEMP

SO

LDE

R

(

C)

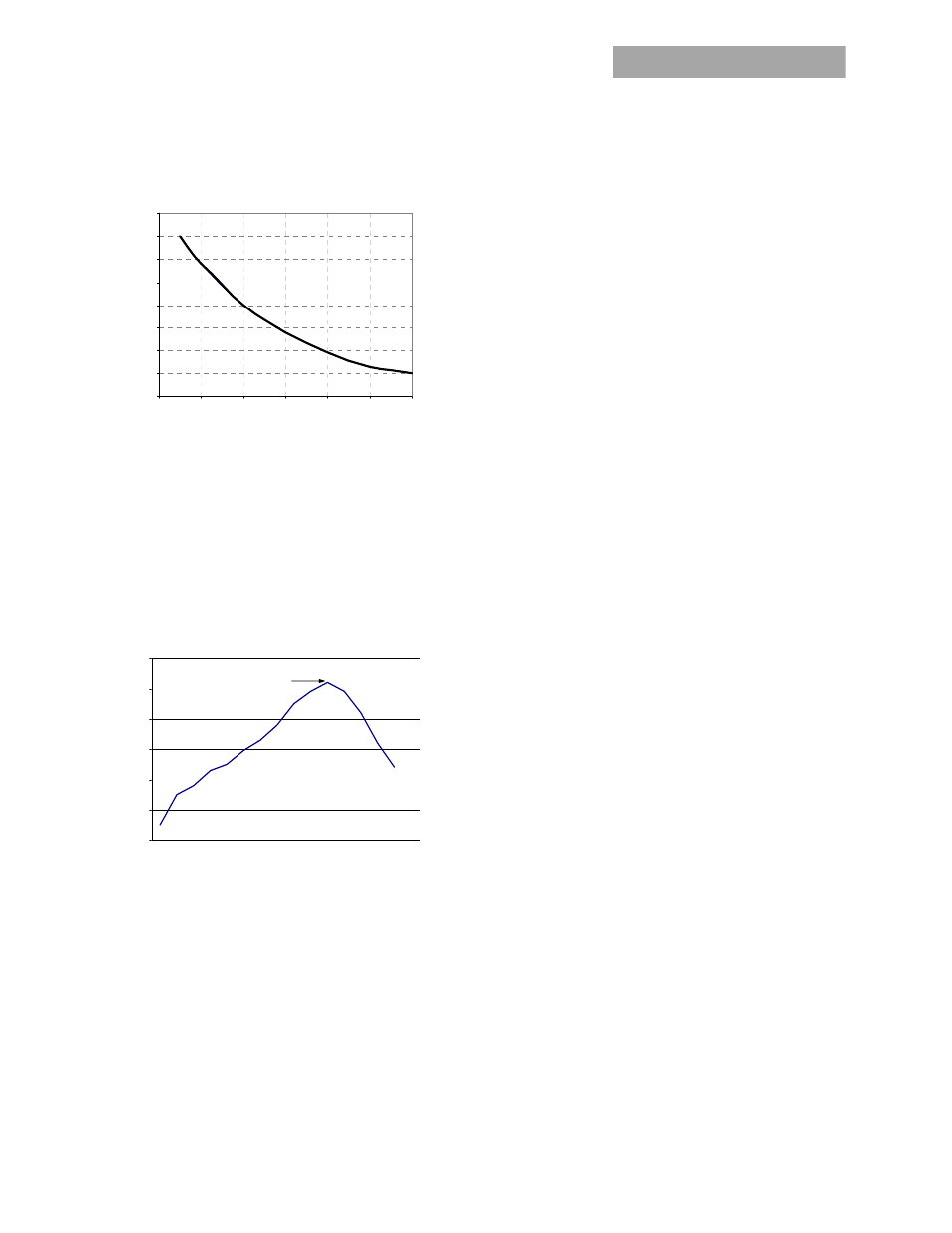

Figure 24. Time Limit Curve Above 205

o

C for Tin/Lead

(Sn/Pb) process

Pb-free Reflow Profile

Power systems will comply with J-STD-015 Rev. C

(Moisture/Reflow Sensitivity Classification for Nonhermetic

Solid State Surface Mount Devices) for both Pb-free solder

profiles and MSL classification procedures. This standard

provides a recommended forced-air-convection reflow

profile based on the volume and thickness of the package

(table 4-2). The suggested Pb-free solder paste is Sn/Ag/Cu

(SAC). The recommended linear reflow profile using

Sn/Ag/Cu solder is shown in Figure 25.

Figure 25. Recommended linear reflow profile using

Sn/Ag/Cu solder.

Post Solder Cleaning and Drying Considerations

Post solder cleaning is usually the final circuit board

assembly process prior to electrical board testing. The result

of inadequate cleaning and drying can affect both the

reliability of a power module and the testability of the

finished circuit board assembly. For guidance on

appropriate soldering, cleaning and drying procedures, refer

to GE Board

Mounted Power Modules: Soldering and Cleaning Application

Note (AN04-001).

200

205

210

215

220

225

230

235

240

0

10

20

30

40

50

60

Per J-STD-020 Rev. C

0

50

100

150

200

250

300

Reflow Time (Seconds)

R

efl

o

w

T

em

p

(°

C

)

Heating Zone

1°C/Second

Peak Temp 260°C

* Min. Time Above 235°C

15 Seconds

*Time Above 217°C

60 Seconds

Cooling

Zone