Product description, Step 1 – unpack and inspect, Step 2 – installation – GE Industrial Solutions Record Plus Wire Connector Lug Kits: FE250 User Manual

Page 2

Product Description

These instructions describe the installation

procedure for the wire connector accessories on

Record Plus™

FE-frame circuit breakers. The wire

connector kits are available in five variants:

Product Catalog

Numbers

Wire Range

FCAL15/ FCALK15

#14-6/0 AWG Al

#4-3/0 AWG

FCALK15LV Control

Wire Terminal Kit

Use 250-series fully insulated

receptacle connectors

(ANSI/NEMA. DC-2-1982)

FCAL16/FCALK16

#8-1 AWG

#1/0-350Kcm

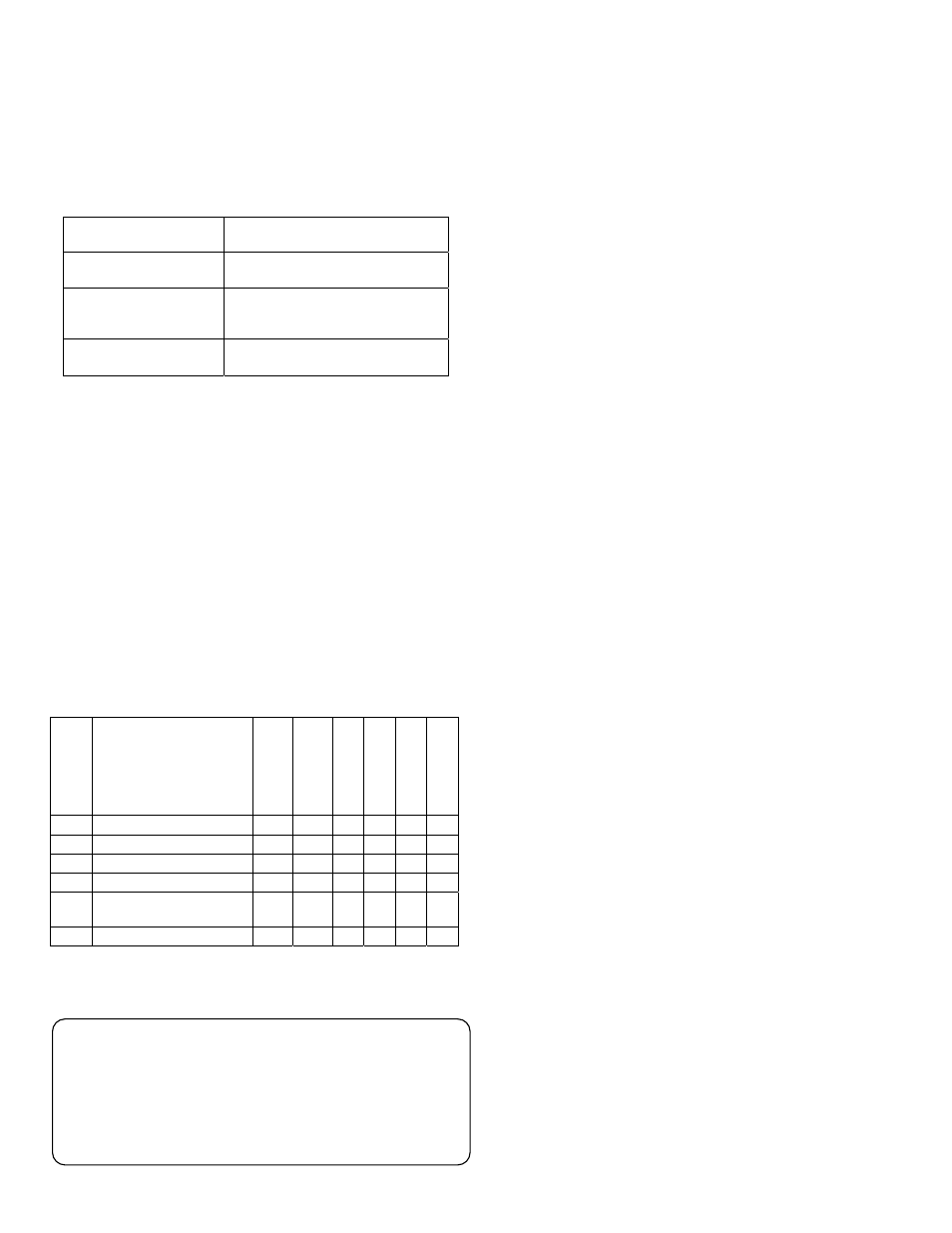

Table 1. List of accessory lug kits.

The FCALK15/FCALK16 kit is suitable for two and

three-pole applications. The FCALK15/FCALK16

kits contain 3 lug wire connectors, a lug cover, and 3

front covers. The FCAL15/FCAL16 catalog number

is a replacement lug kit that contains 1 lug wire

connector and 1 front cover for replacement use.

The FCALK15LV/FCALK16LV kits provide control

wire terminations at the lug.

Step 1 – Unpack and Inspect

Unpack the wire connector kit and inspect the parts

for any shipping damage. Verify that all parts are

supplied, as listed in Table 2 and illustrated in

Figures 1 and 2. Numbers in brackets in the text and

the figures refer to the item numbers in Table 2.

Item Description

FCAL15

FCALK

15

FCALK

15LV

FCAL16

FCALK

16

FCALK

16LV

1 Lug

Cover

1

1

1

1

2

Lug (Wire Connector)

1

3

3

1

3

3

3

Front

Cover

1 3 1 3

4

Control Wire Terminal

3

3

5

Control Wire Front

Cover

3 3

6

Adhesive Base Cover

1

1

1

1

1

1

Table 2. List of parts in the lug accessory kits.

Step 2 – Installation

1. Please review installation instructions fully

before installing lug kit. Lug kit installation

is best done before breaker is mounted.

Installation of front cover [3] (described

below) may best be done before or after

mounting, depending on application.

2. Align lug cover [1] terminal openings with

breaker terminations. Push lug cover

assembly over breaker terminations until lug

cover is seated fully in, as illustrated in Figure

2. Be sure lug [2] is pushed and fully seated

into lug cover [1]. Hex drive of lug screw, lug

cover top hole, and IP20 hole on front face of

breaker should be aligned to allow for hex

driver access to lug screw.

3. Peel off the cover on the Adhesive Base Cover

[6] and affix on the lug cover and breaker

interface on line and load sides as illustrated

in Figure 3.

4. Use joint compound recommended by the

wire manufacturer when using aluminum

wire.

5. Front Cover Installation [3] (Please refer to

Figure 2):

a. FCAL15/FCALK15/FCALK16/FCAL16

Front Cover Installation: Install front covers

[3] by inserting tab into square slot in lug

cover [1] and pushing front cover [3] to seat

on lug cover [1]. This is intended to be a

press fit. Apply pressure to front cover [3] so

that it fully sits on the lug cover [1].

b. FCALK15LV/FCALK16LV Control Wire

Terminal Kit: Place the control wire terminal

[4] on the breaker terminal strap with the lug

[2] installed. Install control wire front covers

[5] by inserting tab into lug cover [1],

guiding the control wire terminal tab [4]

through opening in the front cover [5], and

pushing front cover [5] into press fit on lug

cover [1]. USE ONLY 250-SERIES FULLY

INSULATED UL LISTED RECEPTACLE

CONNECTORS. 90° flag-style connectors are

recommended.

Note: When using aluminum wire, use of a joint

compound recommended by the wire

manufacturer.

Important: Dans les cas d'emploi de cable

aluminum, utilizez le lubricant recommende b

y

par le fabricant.