Car2548dc series dc-dc converters, Data sheet, Control and read accuracy – GE Industrial Solutions CAR2548DC series User Manual

Page 12: Eeprom, Leds

GE

Data Sheet

CAR2548DC series dc-dc converters

Input: -36Vdc to -75Vdc; Output: 48Vdc @ 2500W; 3.3Vdc or 5 Vdc @ 1A

December 6, 2013

©2013 General Electric Company. All rights reserved.

Page 12

Vin_UV_warn_limit (58):

This is another warning flag

indicating that the input voltage is decreasing dangerously

close to the low input voltage shutdown level.

Status_word (79):

returns two bytes of information. The upper

byte bit functionality is tabulated in the Status_word section.

The lower byte bit functionality is identical to Status_byte.

Fan_speed (D7):

This register can be used to ‘read’ the fan

speed in adjustment percent (0 – 100%) or set the fan speed in

adjustment percent (0 – 100%). The speed of the fan cannot

be reduced below what the power supply requires for its

operation. The register value is the percent number, it is not in

linear format.

Invalid commands or data:

The power supply notifies the

MASTER if a non-supported command has been sent or invalid

data has been received. Notification is implemented by setting

the appropriate STATUS and ALARM registers and setting the

SMBAlert# flag.

If a non-supported read is requested the power supply will

return all 0x00h.

Restart after a lachoff:

To restart after a latch_off either of

four restart mechanisms are available. The hardware pin

Remote ON/OFF may be turned OFF and then ON. The unit

may be commanded to restart via i2c through the Operation

command by first turning OFF then turning ON . The third way

to restart is to remove and reinsert the unit. The fourth way is

to turn OFF and then turn ON ac power to the unit. The fifth

way is by changing firmware from latch off to restart. Each of

these commands must keep the power supply in the OFF state

for at least 2 seconds, with the exception of changing to

restart.

A successful restart shall clear all alarm registers.

A power system that is comprised of a number of power

supplies could have difficulty restarting after a shutdown event

because of the non-synchronized behavior of the individual

power supplies. Implementing the latch-off mechanism

permits a synchronized restart that guarantees the

simultaneous restart of the entire system.

A synchronous restart can be implemented by;

1. Issuing a GLOBAL OFF and then ON command to all power

supplies,

2. Toggling Off and then ON the Remote ON/OFF signal

3. Removing and reapplying input commercial power to the

entire system.

It is good practice to turn OFF the power supplies for about 20

– 30 seconds in order to discharge all internal bias supplies

and reset the soft start circuitry of the individual power

supplies.

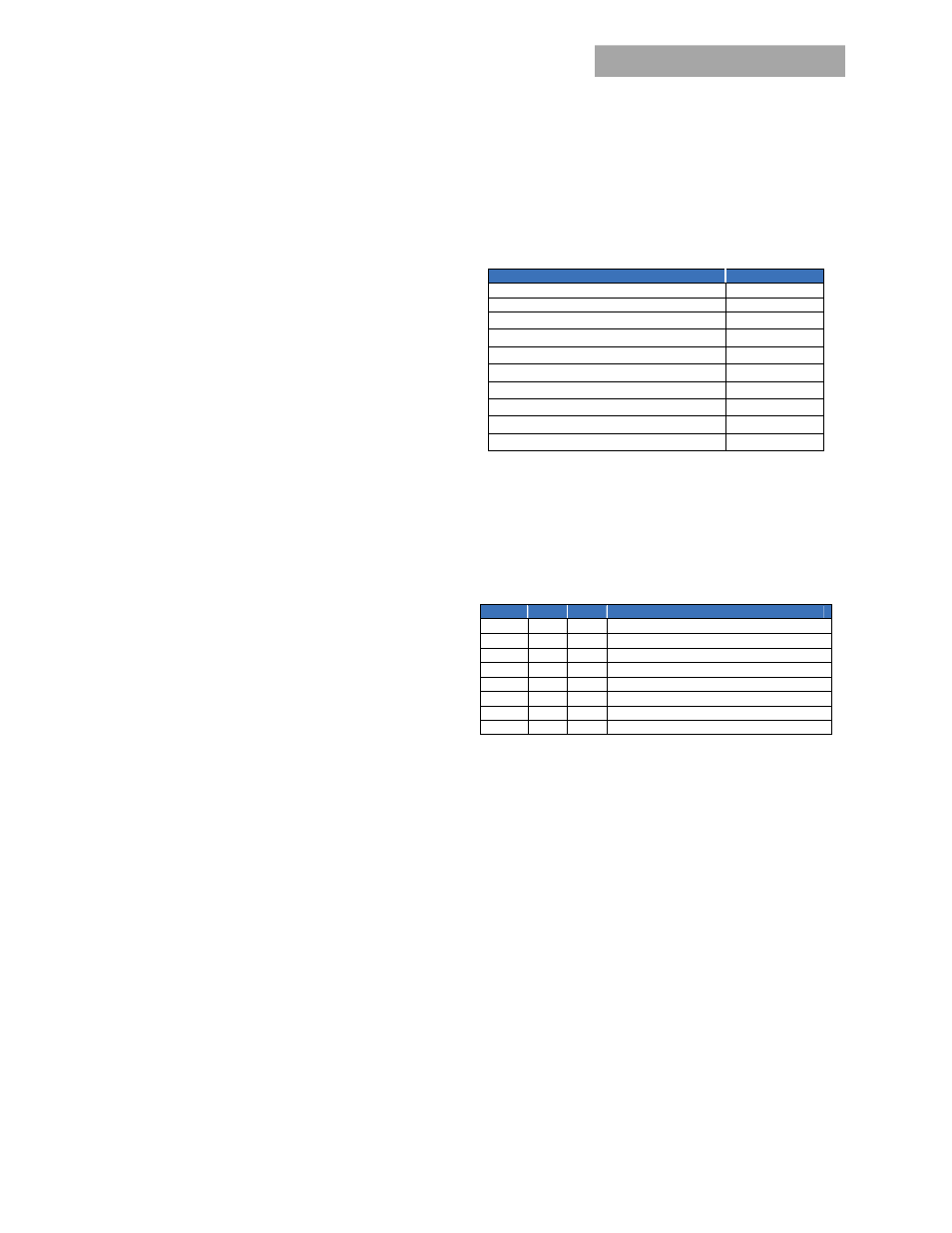

Control and Read accuracy:

The estimates below are believed to be reasonable under most

operating conditions. However, these are typical numbers and

not hard bound values that cannot be exceeded. In most

nominal operating conditions the returned values are

significantly better than these estimates.

FUNCTION

ACCURACY

Vout_command ±

2%

Vout_OV_fault_limit ±

3%

Iout_OC_warn_limit

± 4% of FL

OT_warn_limit

± 5C

Vin_UV_warn_limit

± 3%

Vin_UV_fault_limit

± 3%

Read_Vout

± 2%

Read_Iout

± 4% of FL

Read_temperature

± 5C

Read_Pout

±5%

EEPROM

The microcontroller has 96 bytes of EEPROM memory available

for the system host.

A separate EEPROM IC, with write protect features, provides

another 128 bytes of memory. This EEPROM contains the

following FRU_ID information:

EEPROM: model number, revision, date code, serial number etc.

Offset Length Value

Description

00 7 Serial

number

07 1 20

ASCII

space

08

4

Date code [YY,WW], ASCII numeric value

0C 1 20

ASCII

space

0D

17

Model#, ASCII alphanumeric value

1E 1 20

ASCII

space

1F 1 Revision,

ASCII

value

20-FF 224 FF

LEDs

Three LEDs are located on the front faceplate. When the LEDs

are ON GREEN then input and output are normal.

When the FAULT_LED is RED then a fault condition exists and

the power supply may not provide output power. The table

below further defines these states: