Data sheet, Feature descriptions (continued), Thermal considerations – GE Industrial Solutions EBDW025A0B Barracuda Series User Manual

Page 11

GE

Data Sheet

EBDW025A0B Barracuda™ Series; DC-DC Converter Power Modules

36-75Vdc Input; 12.0Vdc, 25.0A, 300W Output

April 15, 2013

©2012 General Electric Company. All rights reserved.

Page 11

Feature Descriptions (continued)

Power Good, PG

The EBDW025A0B module provides a Power Good (PG) feature,

which compares the module’s output voltage to the module’s

POWER_GOOD_ON and POWER_GOOD_OFF values. These

values are adjustable via PMBus. PG is asserted when the

module’s output voltage is above the POWER_GOOD_ON

value, and PG is de-asserted if any condition such as

overtemperature, overcurrent or loss of regulation occurs that

would result in the output voltage going below the

POWER_GOOD_OFF value.

The PG signal, provided on pin C2, is implemented with an

open-drain node, pulled up via a 10kΩ resistor to 3.3V

internally. For Positive Logic PG (default), the PG signal is HI,

when PG is asserted, and LO, when the PG is de-asserted. For

Negative Logic PG, the PG signal is LO, when PG is asserted,

and HI, when the PG is de-asserted.

The PMBus command MFR_PGOOD_POLARITY is used to set

the logic polarity of the signal.

If not using the Power Good feature, the pin may be left N/C.

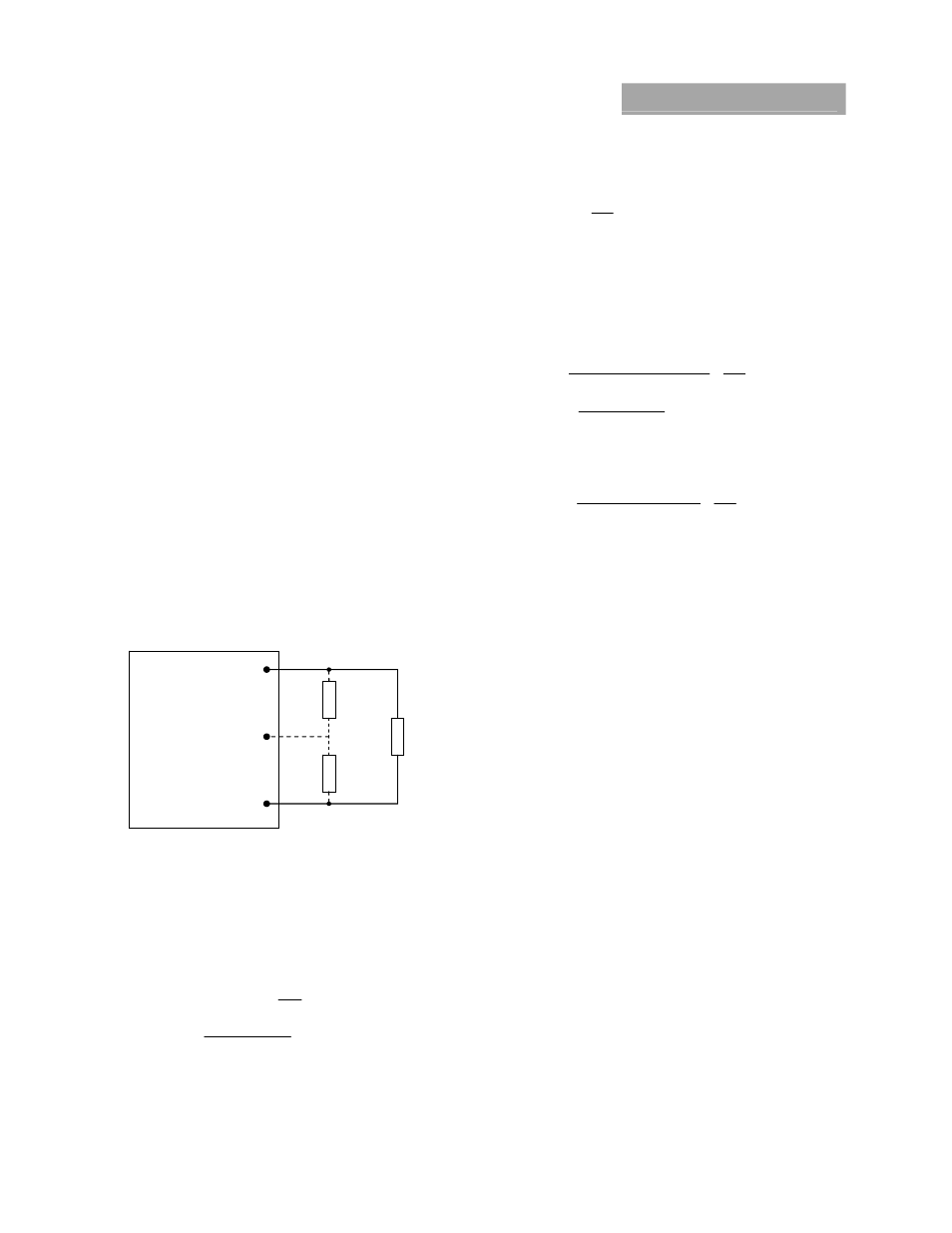

Trim, Output Voltage Programming

Trimming allows the output voltage set point to be increased

or decreased; this is accomplished by connecting an external

resistor between the TRIM pin and either the V

O

(+) pin or the

V

O

(-) pin.

V

O

(+)

T/C1

V

O

(-)

R

trim-down

LOAD

EBDW025A0B

R

trim-up

Figure 17. Circuit Configuration to Trim Output Voltage.

Connecting an external resistor (R

trim-down

) between the T/C1

pin and the Vo(-) (or Sense(-)) pin decreases the output voltage

set point. To maintain set point accuracy, the trim resistor

tolerance should be ±1.0%.

The following equation determines the required external

resistor value to obtain a percentage output voltage change of

∆%.

22

.

10

%

511

down

trim

R

Where

100

0

.

12

0

.

12

%

V

V

V

desired

For example, to trim-down the output voltage of the module

by 20% to 9.6V, Rtrim-down is calculated as follows:

20

%

22

.

10

20

511

down

trim

R

k

R

down

trim

3

.

15

Connecting an external resistor (R

trim-up

) between the T/C1 pin

and the V

O

(+) (or Sense (+)) pin increases the output voltage set

point. The following equations determine the required external

resistor value to obtain a percentage output voltage change of

∆%:

22

.

10

%

511

%

225

.

1

%)

100

(

0

.

12

11

.

5

V

R

up

trim

Where

100

0

.

12

0

.

12

%

V

V

V

desired

For example, to trim-up the output voltage of the module by

5% to 12.6V, R

trim-up

is calculated is as follows:

5

%

22

.

10

5

511

5

225

.

1

)

5

100

(

0

.

12

11

.

5

up

trim

R

8

.

938

up

trim

R

The voltage between the Vo(+) and Vo(–) terminals must not

exceed the minimum output overvoltage protection value

shown in the Feature Specifications table. This limit includes

any increase in voltage due to remote-sense compensation

and output voltage set-point adjustment trim.

Although the output voltage can be increased by both the

remote sense and by the trim, the maximum increase for the

output voltage is not the sum of both. The maximum increase

is the larger of either the remote sense or the trim. The amount

of power delivered by the module is defined as the voltage at

the output terminals multiplied by the output current. When

using remote sense and trim, the output voltage of the module

can be increased, which at the same output current would

increase the power output of the module. Care should be

taken to ensure that the maximum output power of the

module remains at or below the maximum rated power

(Maximum rated power = V

O,set

x I

O,max

).

Thermal Considerations

The power modules operate in a variety of thermal

environments and sufficient cooling should be provided to help

ensure reliable operation.

Thermal considerations include ambient temperature, airflow,

module power dissipation, and the need for increased

reliability. A reduction in the operating temperature of the

module will result in an increase in reliability.

The thermal data presented here is based on physical

measurements taken in a wind tunnel, using automated

thermo-couple instrumentation to monitor key component

temperatures: FETs, diodes, control ICs, magnetic cores,

ceramic capacitors, opto-isolators, and module pwb

conductors, while controlling the ambient airflow rate and

temperature. For a given airflow and ambient temperature, the

module output power is increased, until one (or more) of the

components reaches its maximum derated operating