16v picotlynx, 4a: non-isolated dc-dc power modules, Data sheet – GE Industrial Solutions 16V PicoTLynx 4A User Manual

Page 19

GE

Data Sheet

16V PicoTLynx

TM

4A: Non-Isolated DC-DC Power Modules

8Vdc –16Vdc input; 0.6Vdc to 8.0Vdc output; 4A Output Current

September 10, 2013

©2013 General Electric Company. All rights reserved.

Page 19

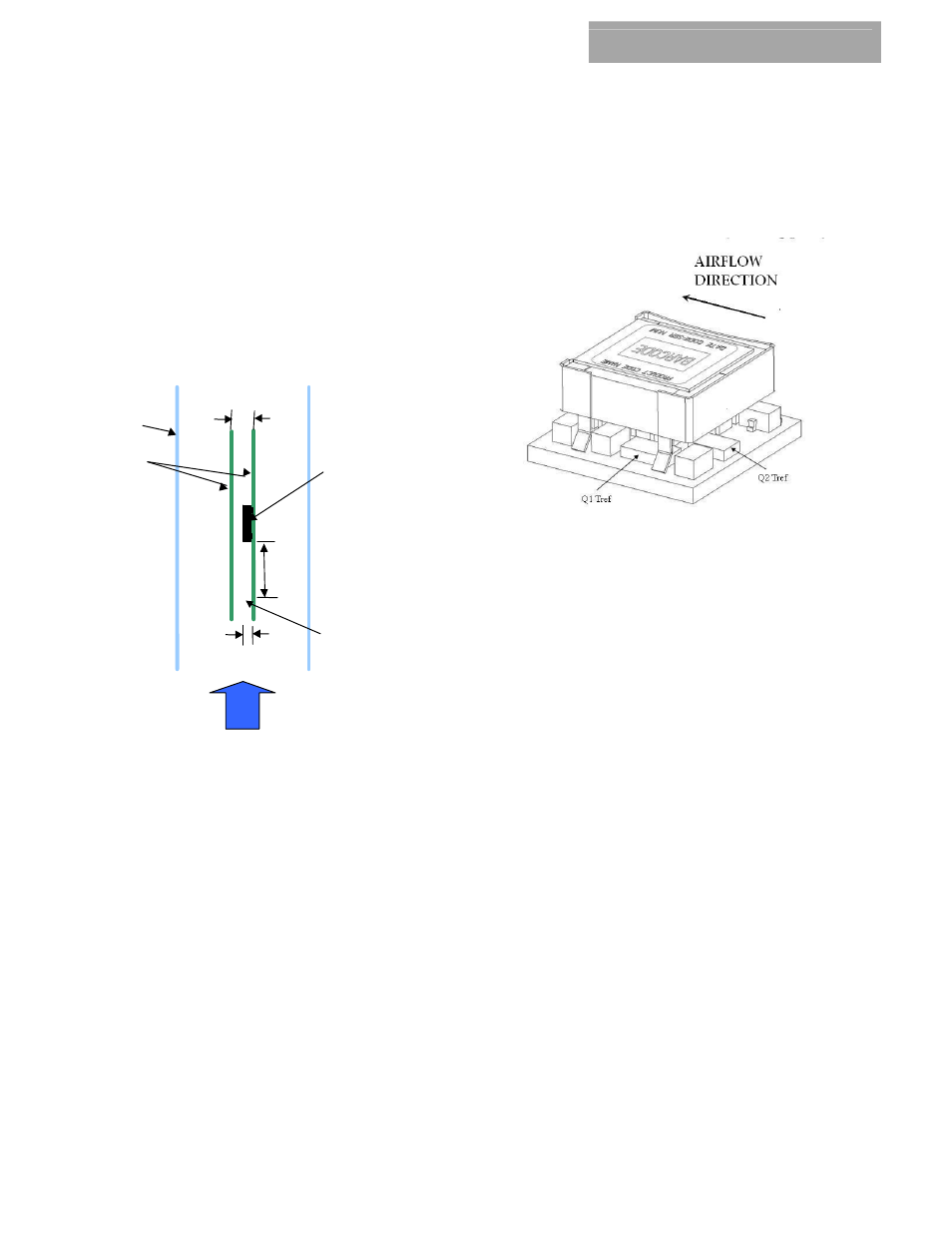

Thermal Considerations

Power modules operate in a variety of thermal environments;

however, sufficient cooling should always be provided to help

ensure reliable operation.

Considerations include ambient temperature, airflow, module

power dissipation, and the need for increased reliability. A

reduction in the operating temperature of the module will

result in an increase in reliability. The thermal data presented

here is based on physical measurements taken in a wind

tunnel. The test set-up is shown in Figure 60. The preferred

airflow direction for the module is in Figure 61.

Air

flow

x

Power Module

Wind Tunnel

PWBs

12.7_

(0.50)

76.2_

(3.0)

Probe Location

for measuring

airflow and

ambient

temperature

25.4_

(1.0)

Figure 60. Thermal Test Setup.

The thermal reference points, T

ref

used in the specifications are

also shown in Figure 60. For reliable operation the

temperatures at these points should not exceed 120

o

C. The

output power of the module should not exceed the rated

power of the module (Vo,set x Io,max).

Please refer to the Application Note “Thermal Characterization

Process For Open-Frame Board-Mounted Power Modules” for a

detailed discussion of thermal aspects including maximum

device temperatures.

Figure 61. Preferred airflow direction and location of hot-

spot of the module (Tref).