Surface mount information, Through-hole lead-free soldering information – GE Industrial Solutions EVW020A0A Series (Eighth-Brick) User Manual

Page 12

Data Sheet

September 7, 2012

EVW020A0A Series Eighth-Brick Power Modules

36–75Vdc Input; 5.0Vdc Output; 20A Output Current

LINEAGE

POWER

12

Surface Mount Information

(continued)

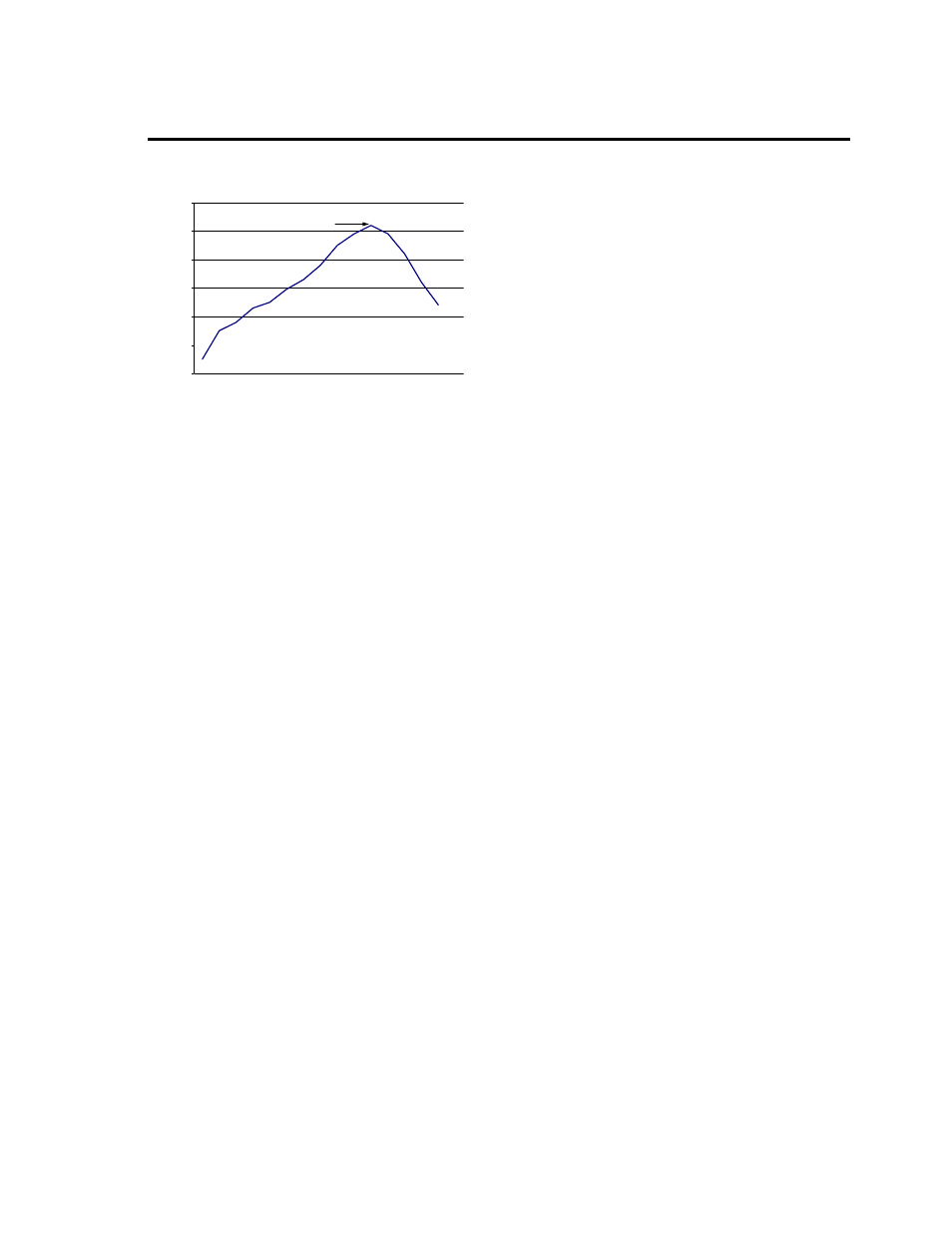

Per J-STD-020 Rev. C

0

50

100

150

200

250

300

Reflow Time (Seconds)

R

efl

o

w

T

em

p

(°

C

)

He ating Zone

1°C/Second

Peak Temp 260°C

* Min. Time Above 235°C

15 Seconds

*Time Above 217°C

60 Seconds

Cooling

Zone

Figure 24. Recommended linear reflow profile

using Sn/Ag/Cu solder.

Post Solder Cleaning and Drying

Considerations

Post solder cleaning is usually the final circuit-board

assembly process prior to electrical board testing. The

result of inadequate cleaning and drying can affect

both the reliability of a power module and the

testability of the finished circuit-board assembly. For

guidance on appropriate soldering, cleaning and

drying procedures, refer to Lineage Power Board

Mounted Power Modules: Soldering and Cleaning

Application Note (AN04-001).

Through-Hole Lead-Free Soldering

Information

The RoHS-compliant through-hole products use the

SAC (Sn/Ag/Cu) Pb-free solder and RoHS-compliant

components. They are designed to be processed

through single or dual wave soldering machines. The

pins have an RoHS-compliant finish that is compatible

with both Pb and Pb-free wave soldering processes.

A maximum preheat rate of 3

C/s is suggested. The

wave preheat process should be such that the

temperature of the power module board is kept below

210

C. For Pb solder, the recommended pot

temperature is 260

C, while the Pb-free solder pot is

270

C max. Not all RoHS-compliant through-hole

products can be processed with paste-through-hole

Pb or Pb-free reflow process. If additional information

is needed, please consult with your Lineage Power

representative for more details.