Figure 7, Step 4 – install a flange stiffener – GE Industrial Solutions Record Plus Variable Depth Operating Mechanism: FE250 User Manual

Page 4

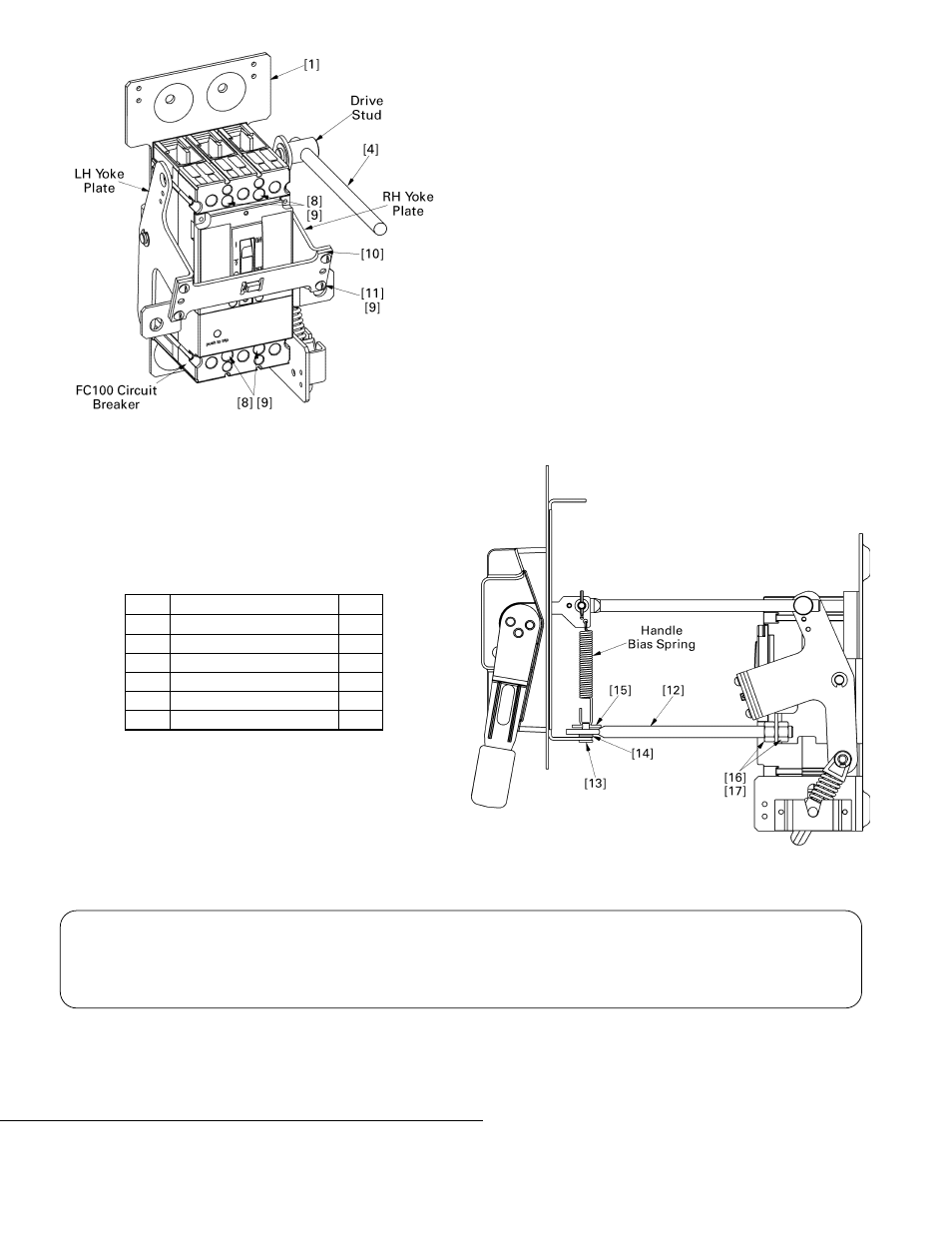

1. Cut the flange stiffener rod [12] 3

1

/

4

" shorter than

dimension D shown in Figure 5 and Figure 6.

2. Disconnect the lower end of the handle bias spring.

3. Screw a nut [16] onto the threaded end of the flange

stiffener rod [12] and place a lock washer [17]

against the nut. Slide the end of the rod through the

mounting hole on the lower part of the operating

mechanism.

4. Insert the drive pin [13] through the hole in the

lower attachment plate on the handle mechanism,

place the flat washer [14] over the end of the drive

pin, then place the hole in the flat end of the rod

[12] over the pin. Slide the cotter pin [15] and the

end of the handle bias spring through the hole in the

top of the drive pin. Bend the legs of the cotter pin

to secure the rod to the drive pin.

5. Place a lock washer [17] and nut [16] over the other

end of the drive rod. Screw the nuts against the

mounting plate on the operating mechanism so that

the flange stiffener rod will prevent the flange on

which the handle is mounted from flexing during

handle operation. Tighten the nuts to 100–150 in-lb.

Figure 7. Circuit breaker installed on the operating mechanism.

Step 4 – Install a Flange Stiffener

Use this procedure, illustrated in Figure 8, if you are

installing an additional rod to prevent flexing of the

flange on which the handle is mounted. Order the flange

stiffener kit, catalog number TDSR, which includes the

Item Description

Qty.

12 Flange stiffener rod

1

13 Drive

pin

1

14 Flat

washer

1

15 Cotter

pin

1

16 Nut,

3

/

8

" 2

17 Lock

washer

2

Table 2. List of parts included in the flange stiffener kit, catalog

number TDSR.

Figure 8. Installing a flange stiffener.

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that

may be met in connection with installation, operation, or maintenance. Should further information be desired or should

particular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the GE

Company. The circuit breaker is a sealed unit that contains no user-serviceable parts. Tampering with the seal will void the

warranty.

g

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

www.geindustrial.com

DEH41014 R02 R0625431

© 2003 General Electric Company