Step 1 – unpack and inspect, Step 2 – install the operating mechanism – GE Industrial Solutions Record Plus Variable Depth Operating Mechanism: FE250 User Manual

Page 2

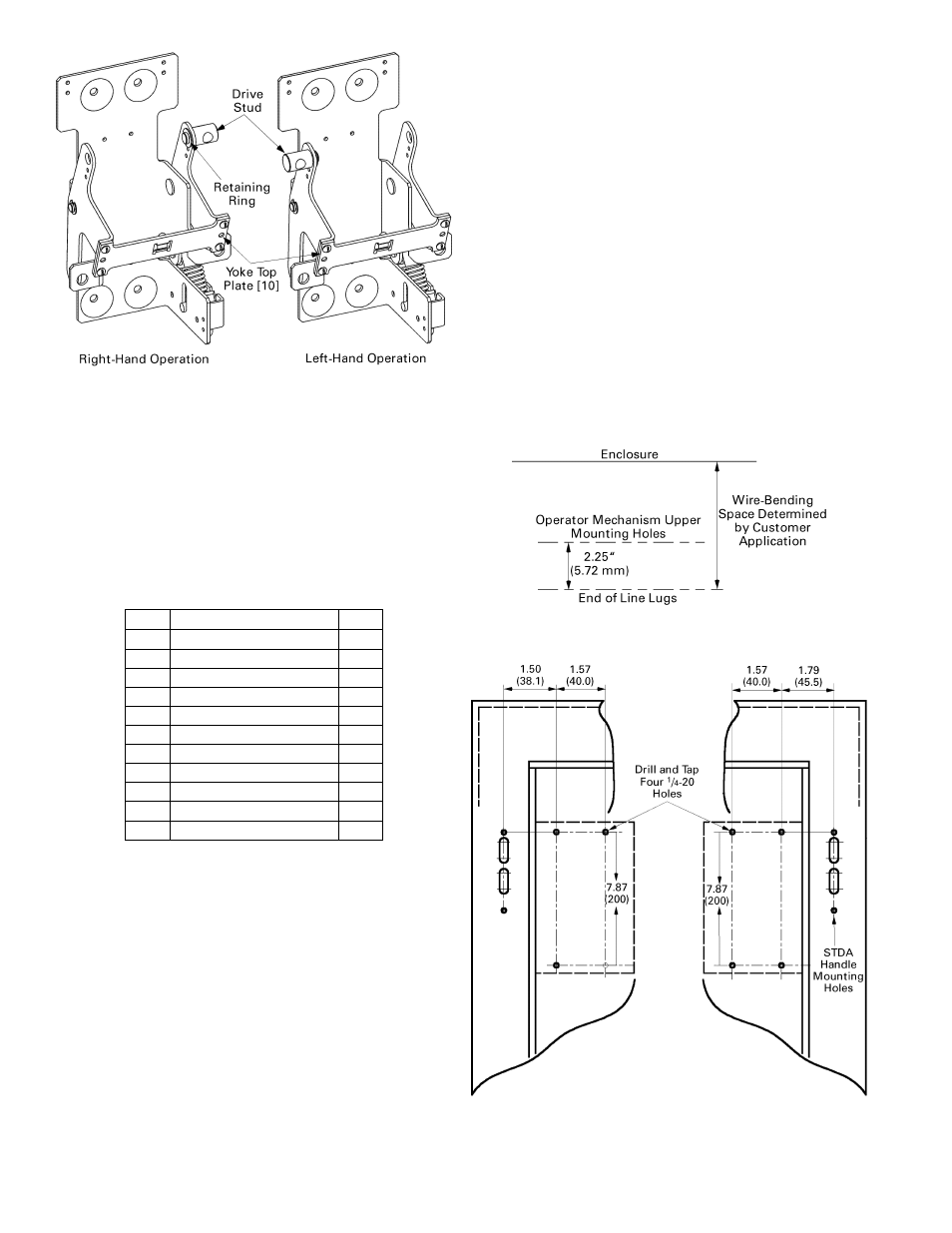

Figure 2. Variable-depth operating mechanism, as set up for right-

hand or left-hand operation.

Step 1 – Unpack and Inspect

Unpack the variable-depth operating mechanism kit and

drive rod kit(s) and inspect the parts for any shipping

damage. Verify that all parts are supplied, as listed in

Table 1.

Note that the numbers in brackets in the following figures

and installation instructions refer to the item numbers in

this table.

Item Description

Qty.

1 Operating

mechanism 1

2 Screw,

1

/

4

-20 x

7

/

16

" 4

3 Lock

washer,

1

/

4

" 4

4 Drive

rod

1

5 Drive

pin

1

6 Flat

washer

1

7 Cotter

pin

1

8

Screw, #8-32 x 2

7

/

8

" 4

9 Lock

washer,

#8

8

10 Yoke top plate

1

11 Screw,

#8-32

x

1

/

4

" 4

Table 1. Parts included in the variable-depth operating mechanism kit,

catalog number FCNFM.

Step 2 – Install the Operating

Mechanism

1. If the operating mechanism is to be installed with

right-hand operation, proceed to step 2. If it is to be

installed for left-hand operation, remove the

retaining ring and drive stud from the right-hand

yoke, as shown in Figure 2, and reinstall them on the

left-hand yoke.

2. The required wire-bending space between the

breaker line lugs and the enclosure end wall is shown

in Figure 3. Use this to determine the operating

mechanism mounting location.

3. Drill and tap four

1

/

4

-20 holes in the enclosure

subplate for mounting the operating mechanism, as

shown in Figure 4. Dimensions for mounting for

both left- and right-hand operation are also shown in

4. Install the type STDA flange-mounted handle

mechanism, as described in the instructions

accompanying the kit (GEH5314).

5. Secure the operating mechanism [1] to the tapped

holes in the enclosure subplate with the four supplied

1

/

4

-20

x

7

/

16

" screws [2] and lock washers [3].

6. As shown in Figure 5 and Figure 6, measure the

dimension D, which is the distance from the handle-

mounting surface to the operating mechanism

mounting surface. Cut the drive rod [4] overall

length 2

1

/

2

" shorter than the D dimension. The

minimum D distance is 6.5" (165 mm).

7. Screw the drive rod [4] into the drive stud on the

operating mechanism until it is flush with the

opposite side of the stud (approximately 10 full

turns), as illustrated in Figure 6.

Figure 3. Wire-bending space between the breaker line lugs and the

enclosure end wall.

Figure 4. Mounting pattern for the operating mechanism.