Car2512fp series rectifier, Data sheet, Input: 90v – GE Industrial Solutions CAR2512FP Front-End User Manual

Page 8: Output: 12 v, Or 5 v, Digital feature descriptions

GE

Data Sheet

CAR2512FP series rectifier

Input: 90V

AC

to 264V

AC

; Output: 12 V

DC

@ 2500W; 3.3V

DC

or 5 V

DC

@ 1A

April 23, 2013

©2013 General Electric Company. All rights reserved.

Page 8

maximum sink current is in compliance to the I²C

specifications.

Serial Data (SDA):

This line is a bi-directional data line. . This

signal is pulled up internally to 3.3V by a 10kΩ resistor. The end

user should add additional pull up resistance as necessary to

ensure that rise and fall time timing and the maximum sink

current is in compliance to the I²C specifications.

Digital Feature Descriptions

PMBus™ compliance:

The power supply is fully compliant to

the Power Management Bus (PMBus™) rev1.2 requirements.

Manufacturer specific commands located between addresses

0xD0 to 0xEF provide instructions that either do not exist in the

general PMBus specification or make the communication

interface simpler and more efficient.

Master/Slave:

The ‘host controller’ is always the MASTER.

Power supplies are always SLAVES. SLAVES cannot initiate

communications or toggle the Clock. SLAVES also must

respond expeditiously at the command of the MASTER as

required by the clock pulses generated by the MASTER.

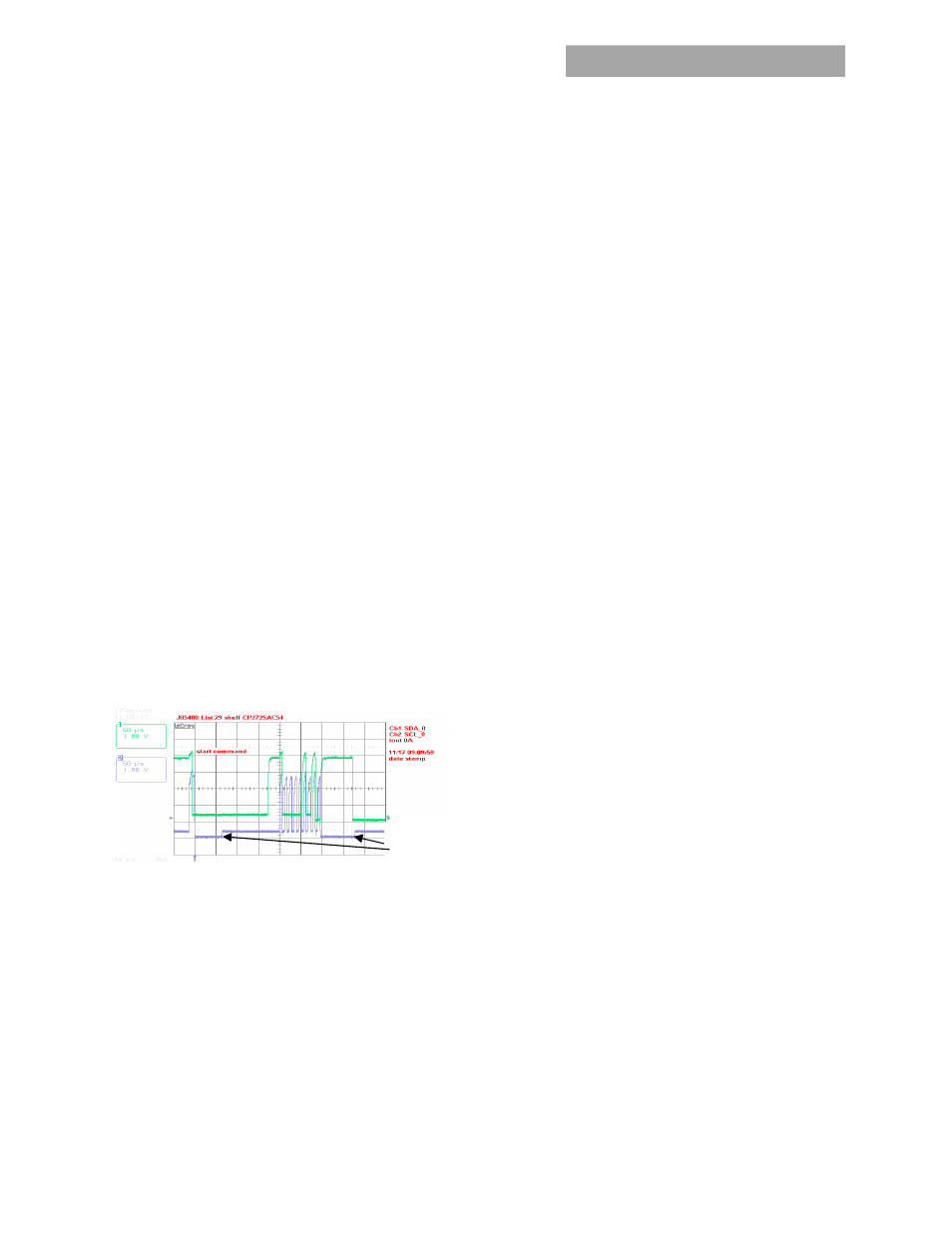

Clock stretching:

The ‘slave’ µController inside the power

supply may initiate clock stretching if it is busy and it desires to

delay the initiation of any further communications. During the

clock stretch the ‘slave’ may keep the clock LO until it is ready

to receive further instructions from the host controller. The

maximum clock stretch interval is 25ms.

The host controller needs to recognize this clock stretching,

and refrain from issuing the next clock signal, until the clock

line is released, or it needs to delay the next clock pulse

beyond the clock stretch interval of the power supply.

Note that clock stretching can only be performed after

completion of transmission of the 9

th

ACK bit, the exception

being the START command.

Figure 1. Example waveforms showing clock stretching.

I

²C Bus Lock-Up detection:

The device will abort any

transaction and drop off the bus if it detects the bus being held

low for more than 35ms.

Communications speed:

Both 100kHz and 400kHz clock rates

are supported. The power supplies default to the 100kHz clock

rate. The minimum clock speed specified by SMBus is 10 kHz.

Packet Error Checking (PEC):

Although the power supply will

respond to commands with or without the trailing PEC, it is

highly recommended that PEC be used in all communications.

The integrity of communications is compromised if packet

error correction is not employed. There are many functional

features, including turning OFF the main output, that should

require validation to ensure that the correct command is

executed.

PEC is a CRC-8 error-checking byte, based on the polynomial

C(x) = x

8

+ x

2

+ x + 1, in compliance with PMBus™

requirements. The calculation is based in all message bytes,

including the originating write address and command bytes

preceding read instructions. The PEC is appended to the

message by the device that supplied the last byte.

SMBAlert#

:

The µC driven SMBAlert# signal informs the

‘master/host’ controller that either a STATE or ALARM change

has occurred. Normally this signal is HI. The signal will change

to its LO level if the power supply has changed states and the

signal will be latched LO until the power supply either receives

a ‘clear’ instruction as outlined below or executes a READ

STATUS_WORD. If the alarm state is still present after the

STATUS registers were reset, then the signal will revert back

into its LO state again and will latch until a subsequent reset

signal is received from the host controller.

The signal will be triggered for any state change, including the

following conditions;

VIN under or over voltage

Vout under or over voltage

IOUT over current

Over Temperature warning or fault

Fan Failure

Communication error

PEC error

Invalid command

Detected internal faults

The power supply will clear the SMBusAlert# signal (release the

signal to its HI state) upon the following events:

Receiving a CLEAR_FAULTS command

The main output recycled (turned OFF and then ON) via

the ENABLE signal pin

The main output recycled (turned OFF and then ON) by the

OPERATION command

Execution of a READ of the STATUS_WORD register

Global broadcast:

This is a powerful command because it can

instruct all power supplies to respond simultaneously in one

command. But it does have a serious disadvantage. Only a

single power supply needs to pull down the ninth acknowledge

bit. To be certain that each power supply responded to the

global instruction, a READ instruction should be executed to

each power supply to verify that the command properly

executed. The GLOBAL BROADCAST command should only be

executed for write instructions to slave devices.

Read back delay:

The power supply issues the SMBAlert #

notification as soon as the first state change occurred.

During

an event a number of different states can be transitioned to

before the final event occurs. If a read back is implemented

rapidly by the host a successive SMBAlert# could be triggered

by the transitioning state of the power supply. In order to avoid

successive SMBAlert# s and read back and also to avoid

reading a transitioning state, it is prudent to wait more than 2

seconds after the receipt of an SMBAlert# before executing a

read back. This delay will ensure that only the final state of the

power supply is captured.

Successive read backs:

Successive read backs to the power

supply should not be attempted at intervals faster than every

Clock

Stretch