H-frame support structure method – Buyers G9003 User Manual

Page 3

Quality since 1946

3

—continued on back

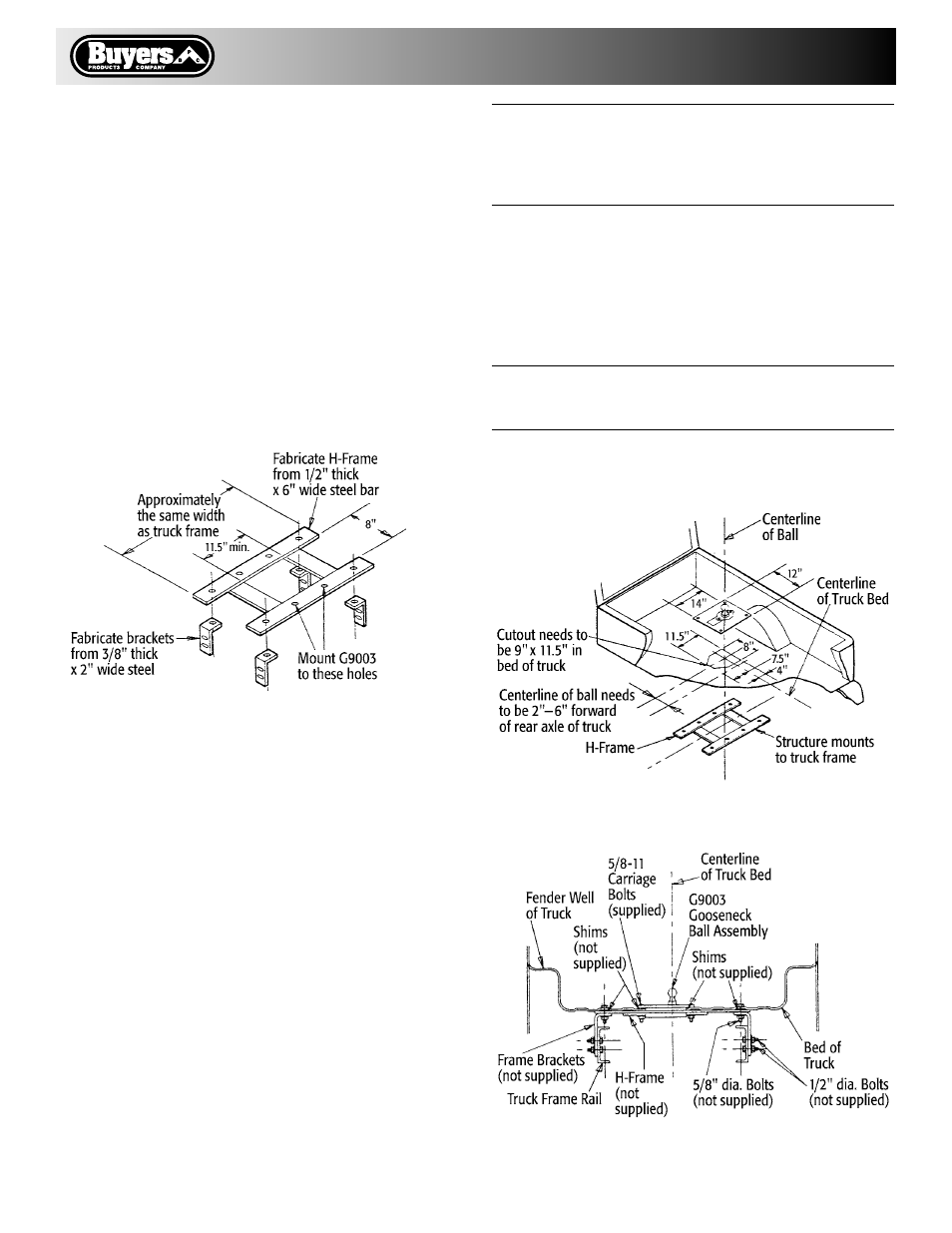

Fig. 6 Components of H-Frame

H-Frame Support Structure Method

A steel bar frame is fabricated as shown in Fig. 6.

1. Install gooseneck ball assembly in truck bed cut-out.

Insure raised ball is centered between truck bed side rails.

2. Mark and drill four 11/16" diameter holes in truck bed

using square holes in gooseneck ball assembly as a guide

for location. See Fig. 7.

3. Position H-frame assembly under floor of truck bed and

above truck frame rails. Line up with bed floor cut-out.

Wedge or clamp in place flush with bottom of truck bed.

4. Drill four 11/16" holes in H-frame using holes drilled in

step 2 as guides.

5. Install the four SAE grade 5, 5/8" diameter carriage bolts

through the gooseneck ball assembly, truck bed, and

H-frame. Install flat washers, lockwashers, and SAE grade 5

nuts. Shim, as required to level corrugations in truck bed.

6. Torque nuts to 60 ft./lbs.

WARNING:

Secure H-frame to truck frame with four 2" wide x 3/8"

thick steel angle brackets, using two per side as shown

in Fig. 6 and Fig. 8. These must be fabricated to fit a

particular truck.

7. Attach brackets to truck bed and H-frame as shown in

Fig. 8. Use SAE grade 5 hex bolts, nuts, and Iockwashers.

Torque to 110 ft/lbs.

8. Drill two 17/32" holes through bracket vertical legs and

truck frame rails.

9. Secure brackets to frame rails with SAE grade 5

1/2" dia. bolts, nuts, and lockwashers. Torque to 60 ft./lbs.

WARNING:

Do not weld brackets to the truck frame.

Use only SAE grade 5 fasteners properly torqued.

10. Proceed with installation check described on page 4.

Fig. 7 Installation of H-Frame

Fig. 8 H-Frame Cut-Away View