Bed plate support structure method – Buyers G9003 User Manual

Page 2

Quality since 1946

2

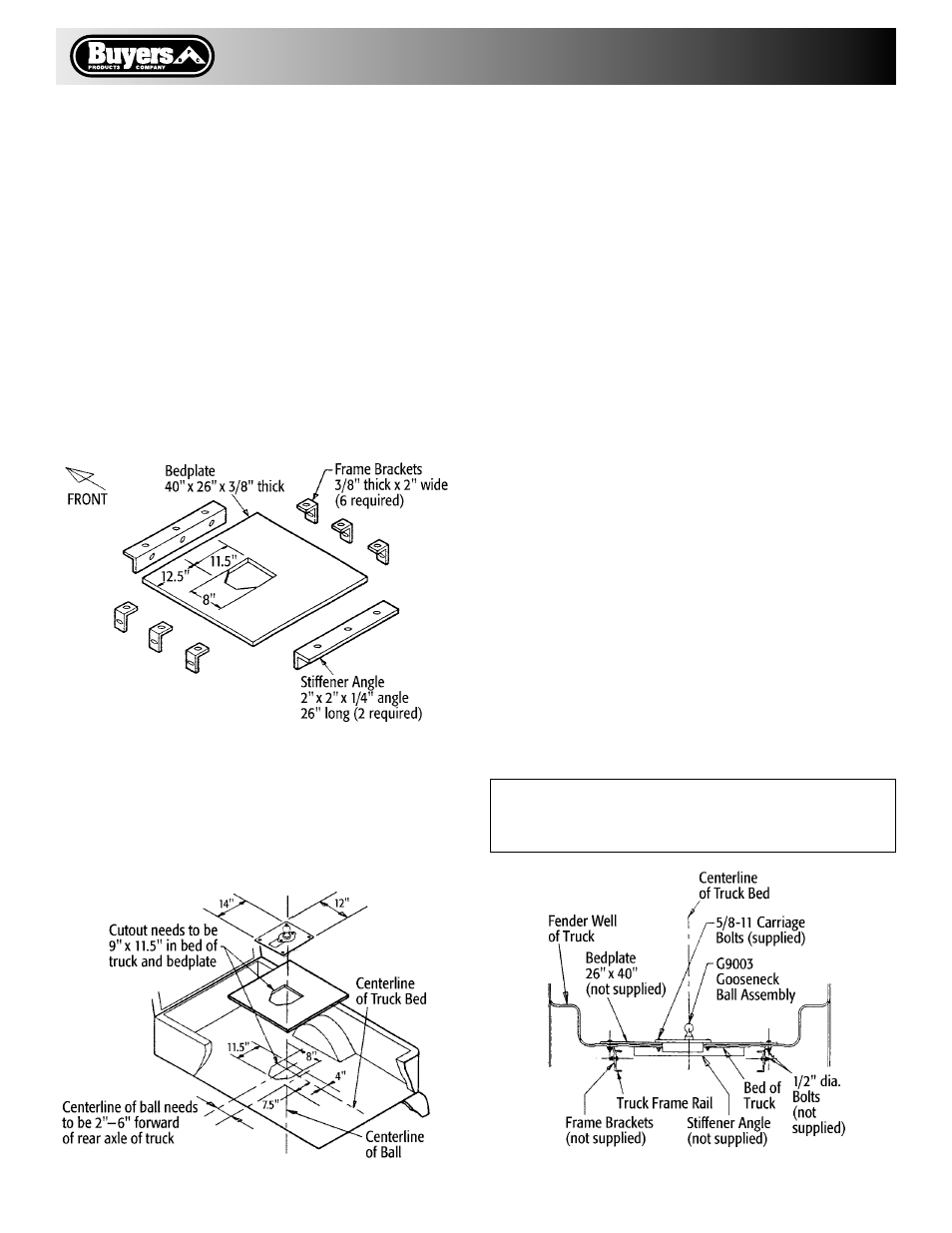

Fig. 3 Bedplate Material

Bed Plate Support Structure Method

Material to be provided by installer:

1 - 26" x 40" x 3/8" thick steel ASTM A-36 steel specifications

2 - 2" x 2" x l/4" thick steel angle iron 26" long ASTM A-36

steel specifications

6 - 3/8" thick x 2" wide steel bar (approximately 6' required:

see note*) ASTM A-36 steel specification

20 - 1/2" x (approximately 2": see note**) SAE grade 5 hex

head cap screws

20 - SAE grade 5 hex nuts

20 - 1/2" lockwashers

• Note*: As truck frames and truck beds vary, this material

must be cut and bent by the installer to fit the particular

application.

• Note**: The length of the 1/2" SAE grade 5 hex head cap

screws may vary to suit particular applications.

• Torque 1/2" SAE grade 5 fasteners to 60 ft. lbs.

• Torque 5/8" SAE grade 5 fasteners to 110 ft. lbs.

1. Place bed plate in the center of the pickup truck bed.

See Fig 4.

2. Align 8" x 11-1/2" cut-out in bed plate with corresponding

cut-out in the truck bed.

3. Place gooseneck hitch ball assembly into the hole in the

bed plate positioning as shown in figure 4.

Fig. 4 Installation of Bedplate

4. Using the four square holes in the gooseneck ball assem-

bly as guides, drill four 11/16" diameter holes through the

bed plate and the truck bed.

5. Install the four grade 5 carriage bolts through the hitch

ball assembly, bed plate and truck bed. Install the flat-

washers under the truck bed using shims to compensate

for the corrugations in the truck bed.

6. Torque the 5/8" hex nuts to 110 ft. lbs.

7. Place the two 2" x 2" x 1/4" thick stiffener angles to the

underside of the truck bed to allow the securing bolts to

pass through the truck bed and the bed plate.

8. Drill four 17/32" holes at the front end area of the bed

plate to mount the forward stiffener angle. Repeat the

operation in the rear end area of the bed plate for the rear

stiffener angle.

9. Fasten front and rear stiffener angles to the underside of

the truck bed with eight SAE grade 5 bolts, nuts and lock-

washers. Torque 1/2" grade 5 hex nuts to 60 ft./lbs.

10. Fabricate six brackets from the 3/8" x 2" bar stock. These

brackets are used to secure the bed plate to the truck frame.

Fabricate three brackets for each side of the bed plate.

11. Installed brackets must fit flush against the frame rail

and the under side of the truck bed. See Fig. 5.

12. Clamp the steel brackets along each side of the truck

frame rail. Drill 17/32" (.531) diameter holes through the

truck bed and the bed plate.

13. Use 1/2" diameter SAE grade 5 bolts, nuts and lockwash-

ers to secure the brackets to the truck bed and bed plate.

14. Drill 17/32" holes through the vertical legs of the steel

brackets and truck frame. Holes should be drilled near the

horizontal center line of the truck frame channel.

15. Use 1/2" diameter SAE grade 5 bolts, nuts and lock-

washers to secure brackets to truck frame.

16. Torque all fasteners to 60 ft./lbs.

17. Proceed with installation check on page 4.

WARNING:

Do not weld brackets to the frame of the truck.

Use SAE grade 5 fasteners properly torqued.

Fig. 5 Bedplate Cut-Away View