Buyers P45AC4 User Manual

Page 3

Quality since 1946

2

3. Clean and inspect the Body for any damage,

which may not have been detected during initial

inspection.

4. Clean the snap ring groove and verify that it has

not been crushed or broken through. If the snap

ring groove is damaged the entire hook must be

replaced.

B. Jaw Kit Installation

1. Apply a liberal amount of a good grease inside

the shaft hole in the Jaw (4). Place the Jaw into po-

sition in the Body and insert the new Shaft (5). Do

not install the Snap Ring at this time.

2. Place a lunette eye of the proper size onto the

hook. With the Jaw resting on the top of the horn,

verify that the Air Chamber will be able to push

the Plunger against the eye.

3. If interference of the Jaw and Plunger will not

allow the Plunger to contact the eye, remove the

Jaw and inspect for any burrs and carefully file

or grind to allow free movement. Care should be

taken not to remove an excessive amount of

material. Reinstall the Jaw and repeat step 2.

4. With the lunette eye in place and the Plunger

held against the eye, verify that the Jaw will not

lift more than 1/2” above the horn as in inspection

step C2.

C. Lock Installation

1. Reassemble the Lock mechanism as described

below in the Lock Kit C4300 section.

D. Secure the Pivot Shaft

1. Install the Rivet by providing a back stop

against the end of the Shaft on the snap ring side

of the hook and driving the Rivet (11) into the hole

provided in the end of the Shaft (eye protection re-

quired.) DO NOT USE THE SNAP RING TO BACK-

UP THE RIVETING.

2. Install the Snap Ring (10) and inspect as shown

in Fig. 1.

LOCK KIT C4300

A. Disassembly

1. Remove the Roll Pin (9) from the Actuator (7),

loosen the Set Screw (8) and pull the Actuator out

of the assembly. This will release the Lock (3) and

the Torsion Spring (6) from the assembly.

B. Lock Installation

1. Install the new Torsion Spring (6) onto the

Actuator so that the left end will rest on the shelf

provided in Body and the right end will insert into

the small hole at the back of the Lock.

2. Take note of the location of the flat area on the

Actuator shaft. Insert the Actuator through the

Lock and the right side hole in the Body. Tighten

the Set Screw (8) against the flat area on the Ac-

tuator.

3. Install the Roll Pin (9) through the hole in the

end of the Actuator.

FULL REBUILD KIT C4400

The Rebuild Kit contains all parts required to

rebuild the P45AC4 Pintle Hook Assembly. The

rebuild procedure is to follow the instructions to:

1. Replace the Jaw and Plunger per Instructions

for Kit C4200; then

2. Replace the Lock per the instructions for

Kit C4300.

3003920 Rev. A

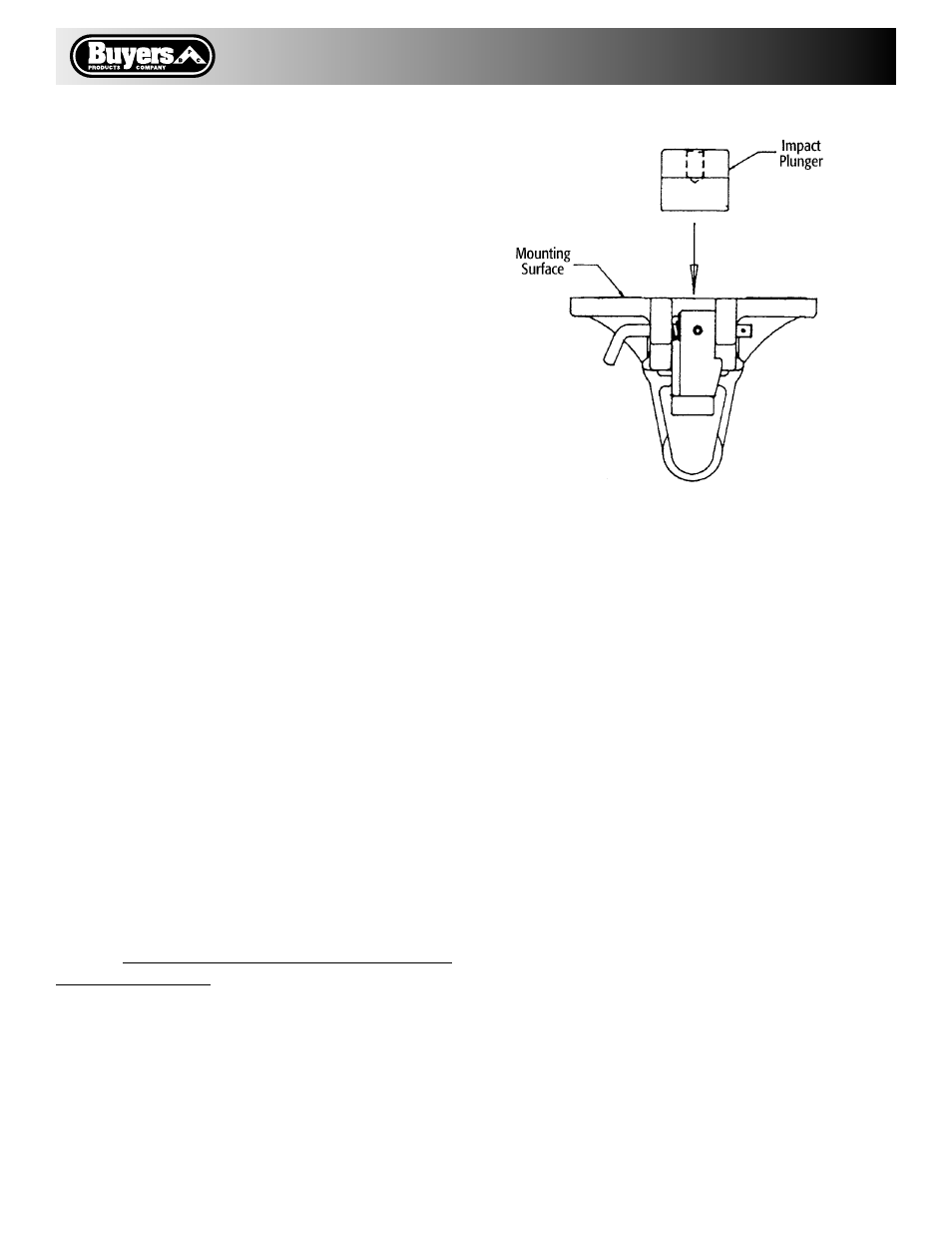

Plunger Installation