Buyers P45AC4 User Manual

Page 2

Quality since 1946

2

Fig. 1

Fig. 2

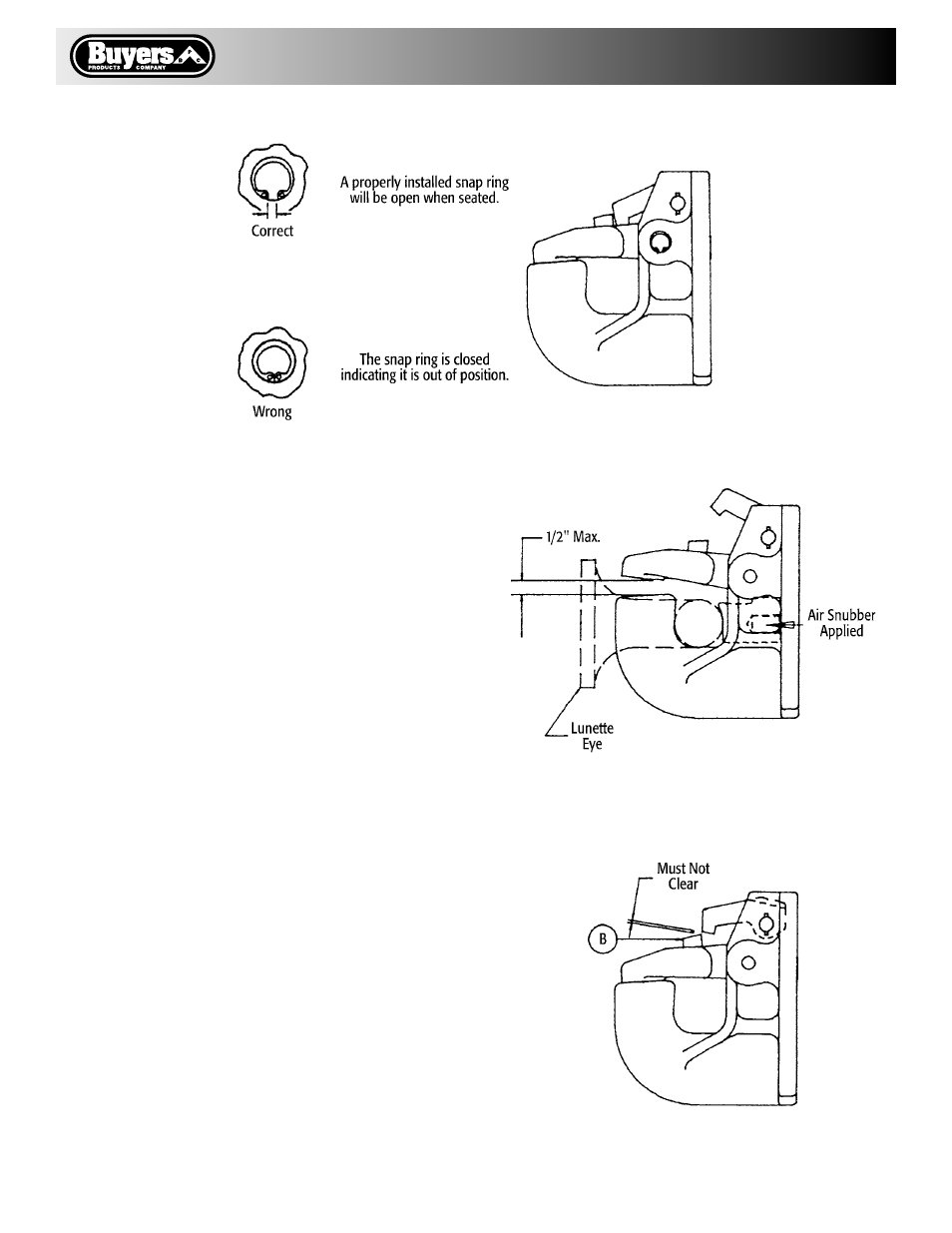

D. Lock Inspection

1. Grasp the Lock Actuator (7) and without com-

pressing the Spring (6) rotate the Actuator handle

to lift the Lock (3) until it stops against the Body

undercut (A). The “tooth” if the Lock must not

clear the stop (B) on top of the Jaw (4). If the lock

clears the stop (B) as shown in Fig. 3.

a. Inspect the undercut (A) on the Body, if the

undercut is not clean and square the entire hook

should be replaced.

b. If the under cut is in good condition, then install

a new Lock Kit C4300 or Rebuild Kit C4400.

E. Full Rebuild

If inspection steps A-D indicate that both the Lock

and Jaw mechanisms require replacement, then

the Rebuild Kit C4400 should be used.

JAW KIT C4200

A. Disassembly

1. Remove the Roll Pin (9) from the Actuator (7),

loosen the Set Screw (8) and pull the Actuator (7)

out of the assembly. This will release the Lock (3)

and the Torsion Spring (6) from the assembly.

2. To remove the Shaft (5) which secures the Jaw

(4), remove the head of the Rivet (11) using a cold

chisel or by grinding (eye protection is required.)

Then remove the Retaining Ring (10) with the

proper snap ring tool. Complete the disassembly

by inserting a pin through the rivet hole in the

Body and driving out the old Shaft.

Fig. 3