Trial results and conclusions – GE P&W FuelSolv - Slag Control Treatment Program at a Southeastern Utility User Manual

Page 9

Technical Paper

Page 9

The untreated opportunity fuel SO

3

baseline was

unavailable, and the SCR is expected to convert

some SO

2

to SO

3

. The testing indicated that the ap-

parent SO

3

removal was within sampling error and

that there was no observable difference in the SO

3

mitigation when MgO addition rates were varied.

Thus, the results did not indicate that the MgO

chemical treatment significantly mitigated SO

3

in

the furnace. However, it is also important to note

that there was no apparent increase in SO

3

for-

mation overall on December 11, when the copper-

based metal oxide slurry was added to the system

(Figure 7).

Trial Results and Conclusions

The magnesium-based product alone showed an

improvement in slag removal until the NAPP blend

increased above 33%. Magnesium alone could not

elevate ash fusion temperature to avoid sticky

deposits in the upper regions of the furnace, Te-

nacious, viscous deposits throughout the boiler

became firmer and were easily removed by IR and

IK sootblowers during the trial once the magnesi-

um and metal oxide products were combined.

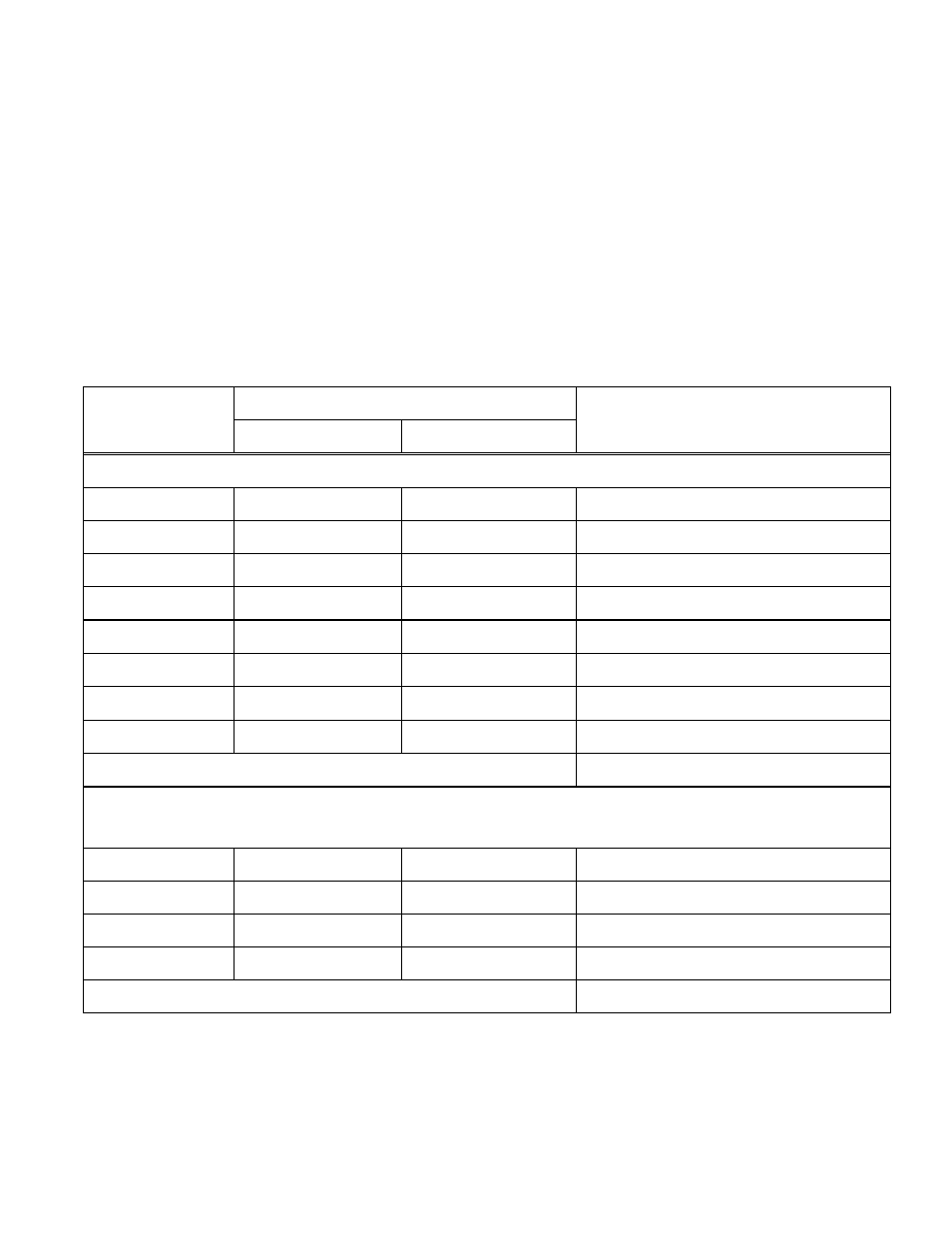

Run No.

Sample Time (EST)

SO

3

Concentration (ppm, dry basis)

Start

End

11/30 and 12/1 – 33% NAPP Coal, 2.0 lb/ton magnesium-based product

1

10:40

11:40

11.3

2

13:05

13:50

12.3

3

14:45

15:30

13.0

4 *

16:25

17:10

6.0

*

5

08:37

09:22

12.4

6

12:10

12:55

9.5

7

14:05

14:50

11.6

8

16:05

16:50

15.3

Average

12.2

12/11 – 50% NAPP Coal, 1.5 lb/ton magnesium-based product

and 0.25 lb/ton metal oxide-based product

9

08:30

09:15

13.6

10

10:05

10:50

12.1

11

11:30

12:15

9.5

12

12:45

13:30

10.4

Average

11.4

Run 4 is suspected as an outlier when compared to other runs under the same operating condition and is not included in the

calculated average.

Figure 7: SO

3

Testing Summary