Boiler and trial design – GE P&W FuelSolv - Slag Control Treatment Program at a Southeastern Utility User Manual

Page 2

Page 2

Technical Paper

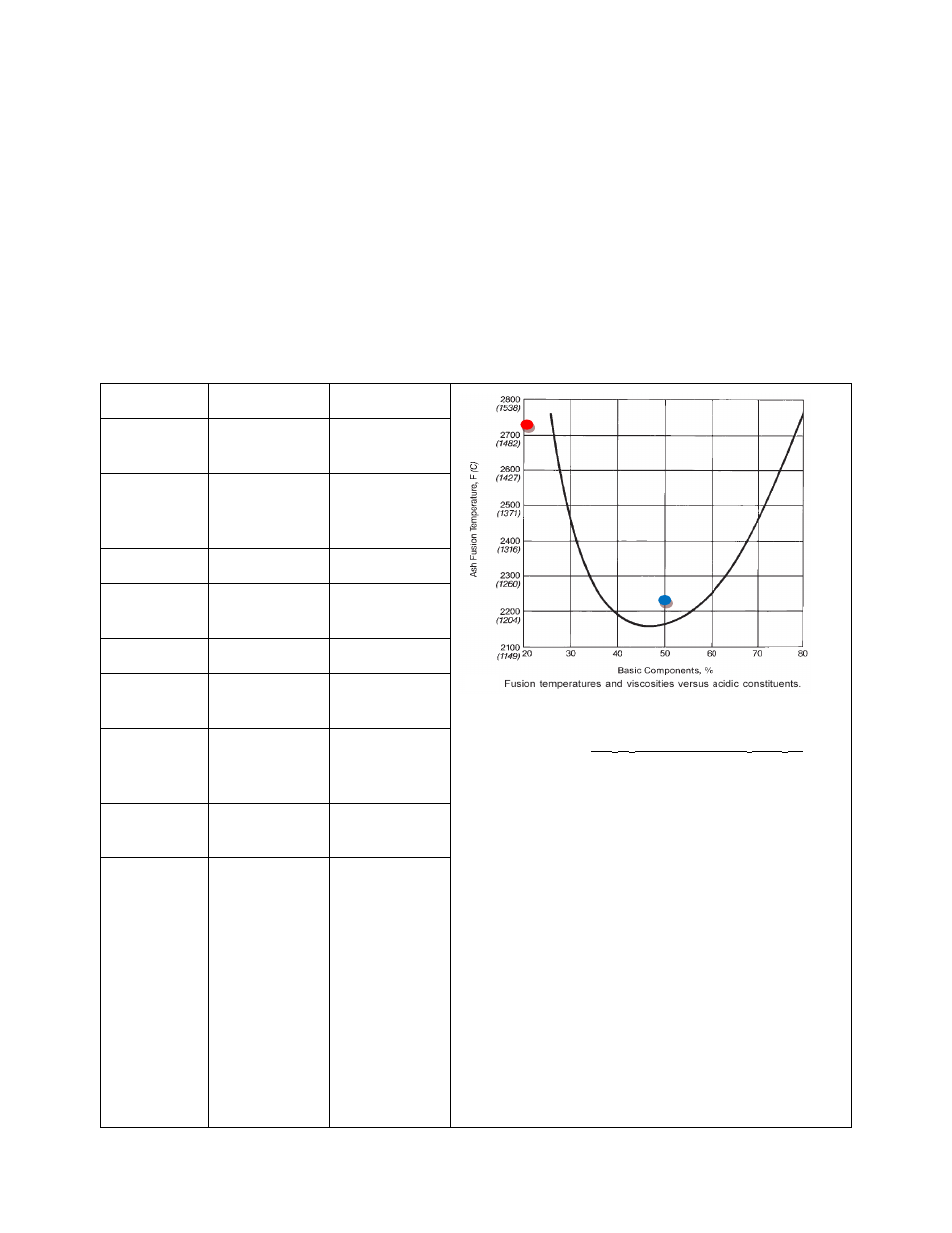

Figure 1: Fuel Comparison and Basicity Ratio (Babcock & Wilcox, 1978)

temperature. Slag deposits are expected to be in

liquid state at furnace temperatures with noncom-

bustible mineral content present. Sootblower clean-

ing alone is not effective when the slag is a liquid or

pseudo-plastic state which deforms under pressure.

Fouling, which is closely related to slagging, usually

occurs in the boiler’s cooler convective back-pass

section as gaseous ash components (such as sodi-

um and potassium) condense. It typically occurs in

the vertical and horizontal reheaters and primary

superheater. Fouling deposits can “bridge” across

tubes and restrict gas flow.

That increases induced fan horsepower, which

raises the plant heat rate and, therefore, lowers

plant efficiency. Slagging and fouling can result in

derating (shedding load) and costly unscheduled

outages and repairs from damaging slag falls. But

these problems can be eased by combining chem-

ical additives for fireside applications with me-

chanical removal (sootblowers).

Boiler and Trial Design

The 745-MW pulverized coal-fired boiler is a Riley

Stoker Corporation front-wall fired boiler with

2,500,000 lbs/hr steam production at 2610 psig

and 1,005 deg F at superheater terminal outlet.

Fuel Type

Typical

Opportunity

** Basicity Ratio = (Fe

2

O

3

+CaO+MgO+Na

2

O+K

2

O)

(SiO

2

+Al

2

O

3

+TiO

2

)

Source

Central

Appalachian

Northern

Appalachian

Cost per

ton, $US

(2010)

$70 – $75

$58 – $70

HHV, Btu/lb

~12,000

~13,000

SO2,

lb/MMBtu

1.1 – 1.5

4.5 – 5.0

Ash, wt%

11 – 12

7 – 8

Moisture,

wt%

6.7 – 7.0

6.0 – 7.0

Ash Soften-

ing Temp,

deg F

2,700

2,250

Basicity

Ratio **

0.12 – 0.14

0.45 – 0.55

Ash, wt%

SiO

2

Al

2

O

3

Fe

2

O

3

K

2

O

TiO

2

MgO

CaO

Na

2

O

53 – 56

28 – 30

5 – 6

3.3 – 3.6

1.3 – 1.5

0.9 – 1.0

0.7 – 1.3

0.2 – 0.3

39 – 40

20 – 21

22 – 24

1.3 – 1.4

0.85 – 0.95

1.05 – 1.15

5 – 6

0.95 – 1.05