Speedhut 2-1_16 inch & 2-5_8 inch Air_Fuel Gauge User Manual

Speedhut For the car

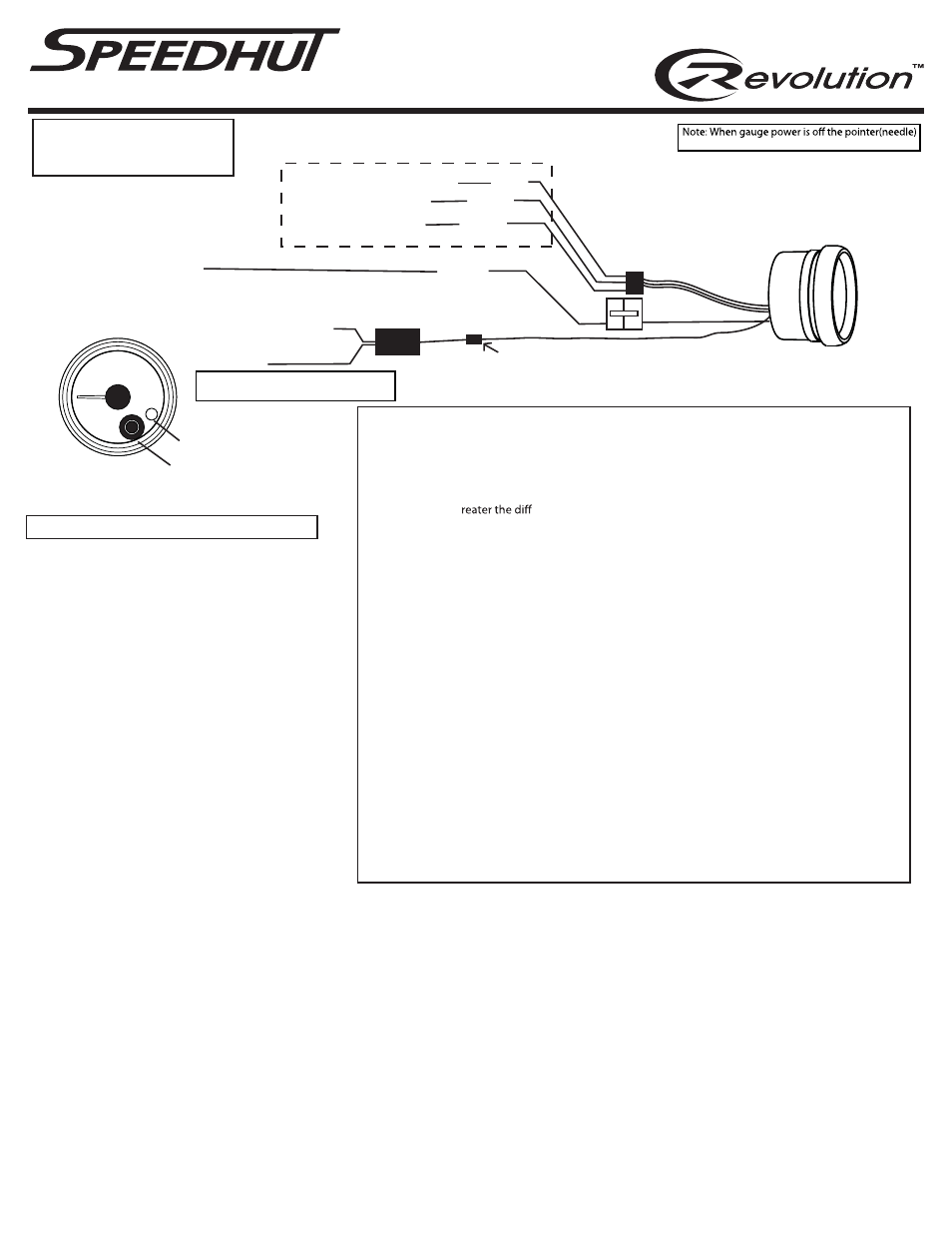

(Yellow)

signal wire

on O2 sensor

O2 theory of operation

Oxygen sensors produces a voltage signal that recognizes the amount of unburned oxygen in

the exhaust. An oxygen sensor is essentially a battery that generates its own voltage. When hot

(at least 250C), the zirconium dioxide element in the sensor's tip produces a voltage that varies

according to the amount of oxygen in the exhaust compared to the ambient oxygen level in the

outside air. The g

erence, the higher the sensor's output voltage.

Sensor output ranges from aprox 0.2 Volts (lean) to 0.8 Volts (rich). A perfectly balanced or

"stoichiometric" fuel mixture of 14.7 parts of air to 1 part of fuel gives an average reading of

around 0.45 Volts.

Since O2 sensors aren't terribly accurate when representing air/fuel ratios higher or lower than

stoichiometric (a "perfect" air/fuel ratio of 14.7 parts air to 1 part fuel), the ECM likes to see the

sensors cross over the stoichiometric mid-point (a voltage around 450mV) as often as possible.

That's a pretty good indication the engine is running near its optimal air/fuel ratio. A "lazy"

worn-out sensor crosses over the mid-point less frequently, costing power and increasing

emissions.

The Speedhut Air/fuel gauge is designed to work with factory OEM O2 sensors operating from

0-1 volts. The gauge will work with both heated and non heated O2 sensors. In normal

operation gauge pointer will slightly oscillate back and forth within the stoich range of dial

indicating a properly functioning O2 sensor and good air/fuel mixture. Under heavy

load/acceleration the pointer will move into the rich area of dial as the ECM module takes over

using pre programmed fuel delivery curves- this is normal. Under heavy deceleration the

pointer could momentarely move to lean condition. However, a pointer that tends to oscillate

back and forth in the lean or rich areas indicates improper fuel mixture.

Lean range - 0 - .249v

Stoichiometric range .250 - .749v

Installation

1.Disconnect negative (-) Battery Cable

2.Connect wiring as above.

3.Mount Gauge for easy viewing. Use spin lock

ring (included) to mount to panel. Spin ring threads

in both directions (depending on your dash panel

thickness). Snap Gauge connector to wiring

connector.

4.Reconnect negative (-) battery cable.

LED button

LED

+12 volts keyed ignition

(Red)

(Black)

Ground

(White)

+12 volts Dash lighting

(dial lighting wire)

Ground (black)

+12 volts Dash lighting (white)

snap connector

(Pointer lighting wire)

2-1/16" and 2-5/8"

Air/Fuel Gauge Instructions

INVERTER

INVERTER IS REQUIRED FOR GAUGE DIAL LIGHTING

(Main gauge power)

Note: Tie both lighting white wires together

and both black ground wires together.

Inverter Note: E18-686-5CR is single gauge inverter to light single gauge.

C01-18N-2 & C11-18A01 are multiple gauge lighting inverters that can light

up to 6 - 8 gauges depending on inverter model.

will remain in last powered position.

Power Draw = 0.2 Amp

5 Amp Inline Fuse Recommended

for +12 Keyed Ignition