Troubleshooting – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1895 User Manual

Page 54

7. Troubleshooting

54

PNEG-1895 V2 Electronic Distributor Control

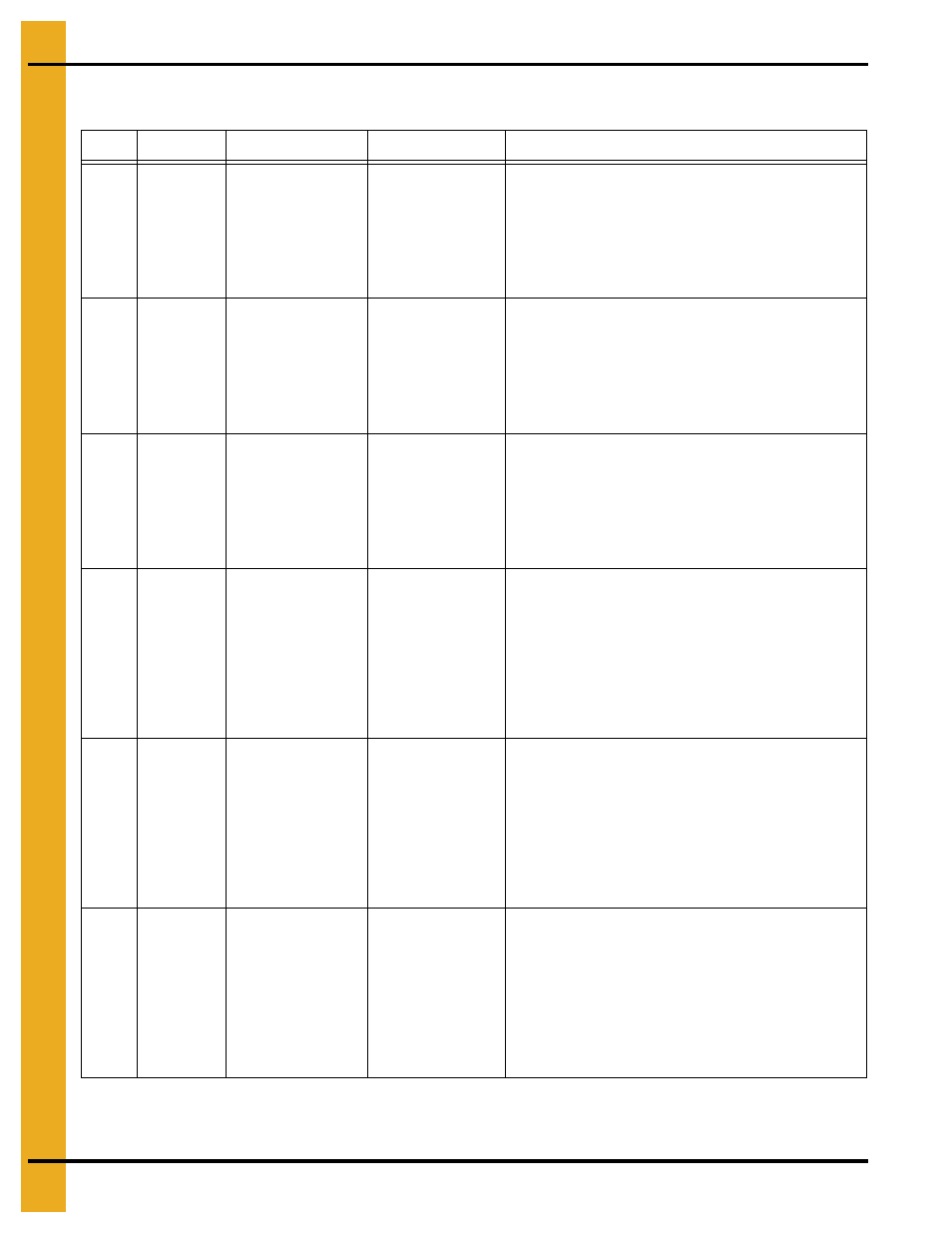

Fault Code Descriptions, Possible Causes and Solutions

Code

Fault Type

Description

Cause

Solution

101

Direction

Motor Direction

Forward, Encoder

Reading Reverse

Motor wiring or

encoder signal

wiring is reversed.

Using manual key switch, verify that forward command

produces counter-clockwise (as observed from above)

distributor rotation. If distributor rotates clockwise (as

observed from above), swap any two (2) motor leads to

reverse motor rotation direction. If motor direction is

correct, check blue terminals 3 and 4 for correct wiring

both at junction box and control panel.

102

Direction

Motor Direction

Reverse, Encoder

Reading Forward

Motor wiring or

encoder signal

wiring is reversed.

Using manual key switch, verify that forward command

produces counter-clockwise (as observed from above)

distributor rotation. If distributor rotates clockwise (as

observed from above), swap any two (2) motor leads to

reverse motor rotation direction. If motor direction is

correct, check blue terminals 3 and 4 for correct wiring

both at junction box and control panel.

201

Encoder

Encoder Channel A

is OFF, Encoder

Channel B is OFF

Controller is

detecting no signal

from encoder

channel A or

encoder channel B.

Verify encoder wiring per instructions in this manual.

Encoder connections are blue terminal blocks. Blue

terminal block #1 should be connected to red encoder

wire. Blue terminal block #2 should be connected to

blue encoder wire. Blue terminal block #3 should be

connected to pink encoder wire. Blue terminal block #4

should be connected to white encoder wire.

202

Encoder

Encoder Channel A

is OFF, Encoder

Channel B is ON

Controller is

detecting no signal

from encoder

channel A,

channel B is always

ON.

Controller is receiving no signal from channel A (blue

terminal block #3) and a constant signal from channel B

(blue terminal block #4). Verify encoder wiring as

referenced above and ensure all terminal blocks are

secure with proper electrical continuity. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.

203

Encoder

Encoder Channel A

is ON, Encoder

Channel B is OFF

Controller is

detecting encoder

channel A always

ON, channel B no

signal.

Controller is receiving a constant signal from channel A

(blue terminal block #3) and no signal from channel B

(blue terminal block #4). Verify encoder wiring as

referenced above and ensure all terminal blocks are

secure with proper electrical continuity. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.

204

Encoder

Encoder Channel A

is ON, Encoder

Channel B is ON

Controller is

detecting encoder

channel A and

channel B always

ON.

Controller is receiving a constant signal from channel A

(blue terminal block #3) and a constant signal from

channel b (blue terminal block #4). Verify that encoder

ground (blue terminal block #2) is secure with proper

electrical continuity at all terminations. If wiring is

correct and all terminals have continuity, check for 24V

across terminals 1 and 2. If encoder has 24V power

and problem persists the encoder has likely failed.

Replace encoder.