Start-up checklist, Operation procedures – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1895 User Manual

Page 20

4. Operation Procedures

20

PNEG-1895 V2 Electronic Distributor Control

Start-Up Checklist

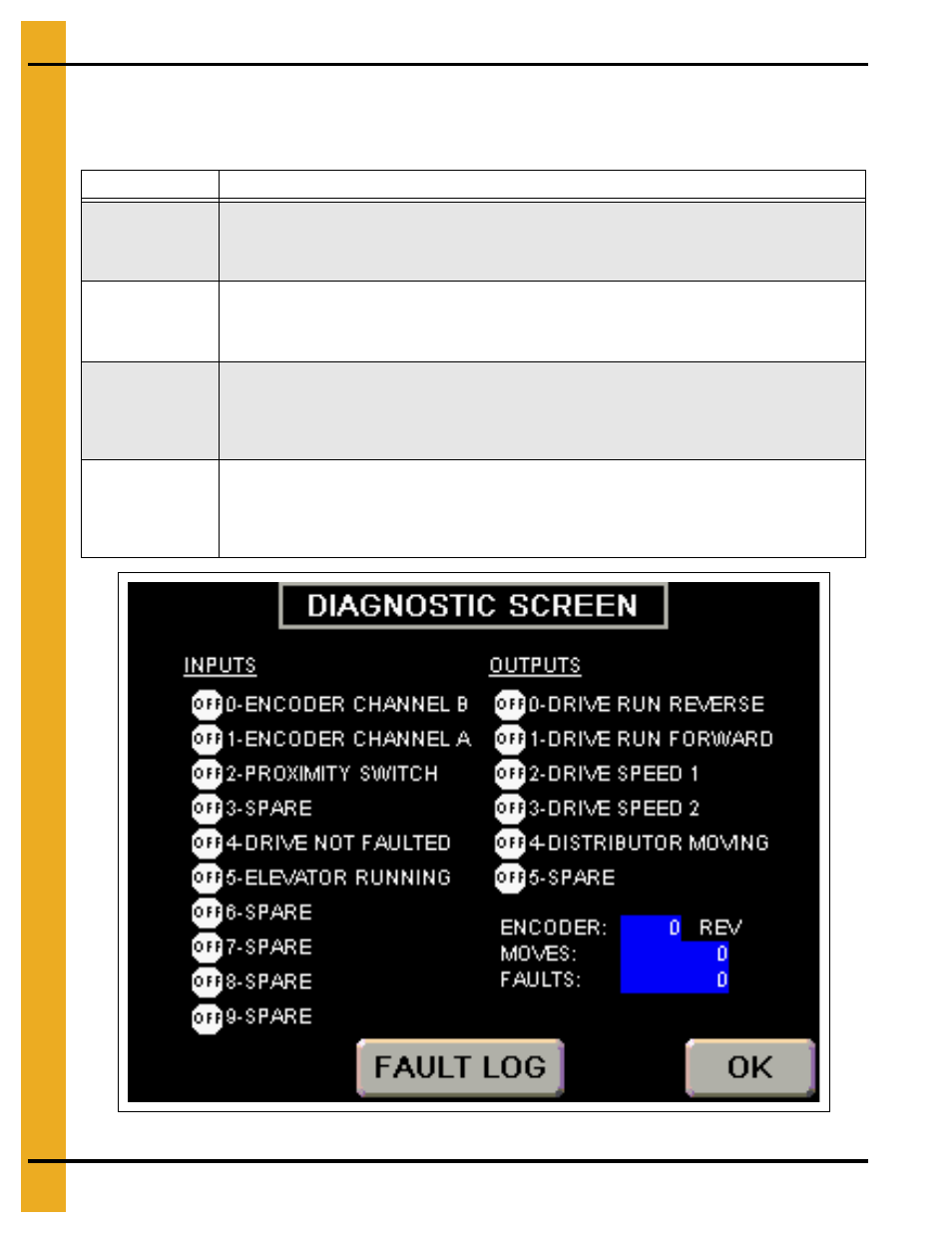

Press “Diagnostic Screen” button to enter diagnostic menu to complete the following checklist:

Figure 4B Diagnostic Screen

Check

Procedure

Motor Direction

Insert key into key switch override on front of control panel. Rotate switch to forward “FWD” position

for 4 seconds. Verify that “DIRECTION” in bottom right hand corner reads “FORWARD” during this.

If “REVERSE” is displayed after 4 seconds, reverse any two (2) motor leads on motor or VFD to

correct rotation direction.

Encoder Function

Using key switch, rotate switch to reverse “REV” position for 4 seconds. Verify that inputs 0 and 1.

(Labeled ENCODER CHANNEL A and ENCODER CHANNEL B in top left hand corner of screen.)

Toggle ON and OFF while switch is held in reverse position. If either channel fails to toggle ON or OFF,

verify that encoder is wired correctly.

Home Prox Test

Using a second person as a spotter, use key switch to rotate spout in reverse direction until the “flag”

welded to the drive shaft is positioned over the top of the “home” proximity switch. (Located on side of

sensor mounting plate labeled “RED”.) Verify that when flag is positioned above proximity switch, input

2 labeled “HOME PROX SWITCH” turns green and shows “ON” on diagnostic screen. If input does not

show “ON”, check that gap between switch and flag is 0.050" ± 0.010".

Overtravel Test

Using a second person as a spotter, use key switch to rotate spout in forward direction until the “flag”

welded to the drive shaft is positioned over the top of the “overtravel” proximity switch. (Located on

side of sensor mounting plate labeled “GREY”.) Verify that when flag is positioned above proximity

switch, input 2 labeled “OVERTRAVEL PROX” turns green and shows “ON” on diagnostic screen.

If input does not show “ON”, check that gap between switch and flag is 0.050" ± 0.010".