2 adjustment – VEGA VEGATOR 632 User Manual

Page 31

Mode

Level

Channel 1

Channel 2

Control lamps

Two-point

control -

min.

6

4

5

16

17

15

ye ye

gn rd

Level detection with one switching point - Fault signal with relay

output 2

Switching reaction of channel 1 see "CH 2 output separate".

l

Dry run protection (min.) or overfill protection (max.)

l

Channel 1 (switching relay) and channel 2 (fail safe relay) - (CH 1

with alarm)

8

.2 Adjustment

Standard adjustment for conductive liquids.

Specifications:

The probe is covered with medium.

1

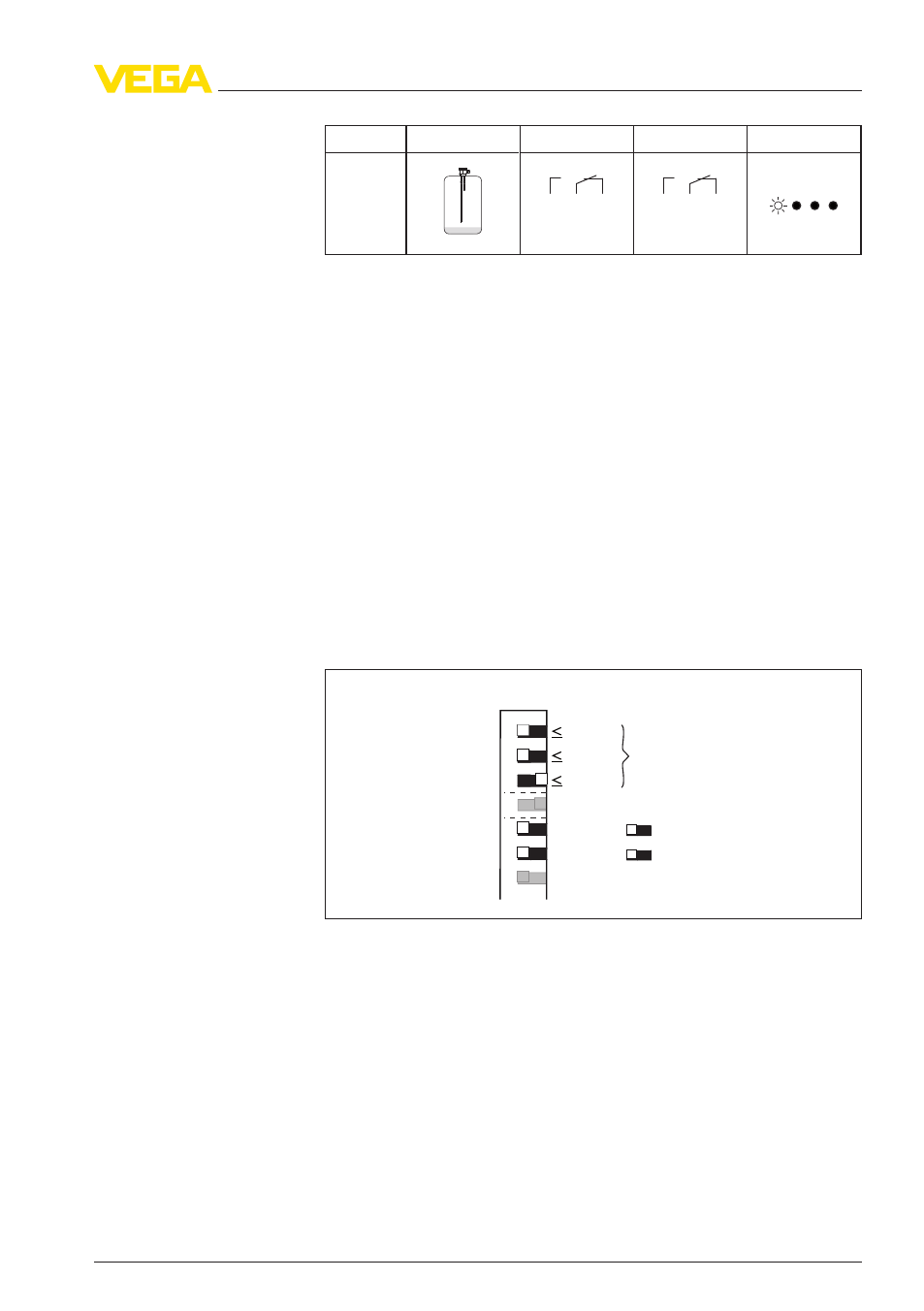

Set DIL switch 1 to 3 on the DIL switch block (A) according to the

following illustration

1 K

Ω

10 K

Ω

200 K

Ω

200 K

Ω

CH1

CH2

max.

max.

off on

1

2

3

4

5

6

7

Fig. 95: Conductive liquids up to 200 kΩ

2

Turn potentiometer (B) to complete left position

3

Turn potentiometer (B) slowly clockwise until the relay output

switches and the yellow control lamp changes condition

4

Turn the potentiometer approximately 15° in the same direction

5

If the relay output does not change, you have to switch to the next

range.

If the relay output has switched, empty the vessel until the electrode is

uncovered.

The relay output must now switch again.

CH 1 with alarm

Adjustment with con-

ductive liquids

VEGATOR

632 • Signal conditioning instrument

31

8 Set up - Two-point control Δs (pump control)

35243

-EN

-120228