Veris Industries EP2 SERIES Install User Manual

Notice, Electropneumatic transducer, Installation guide

Z203044-0U

PAGE 1

©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

07121

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

EnvironmEntal SEnSorS

inStallation GUiDE

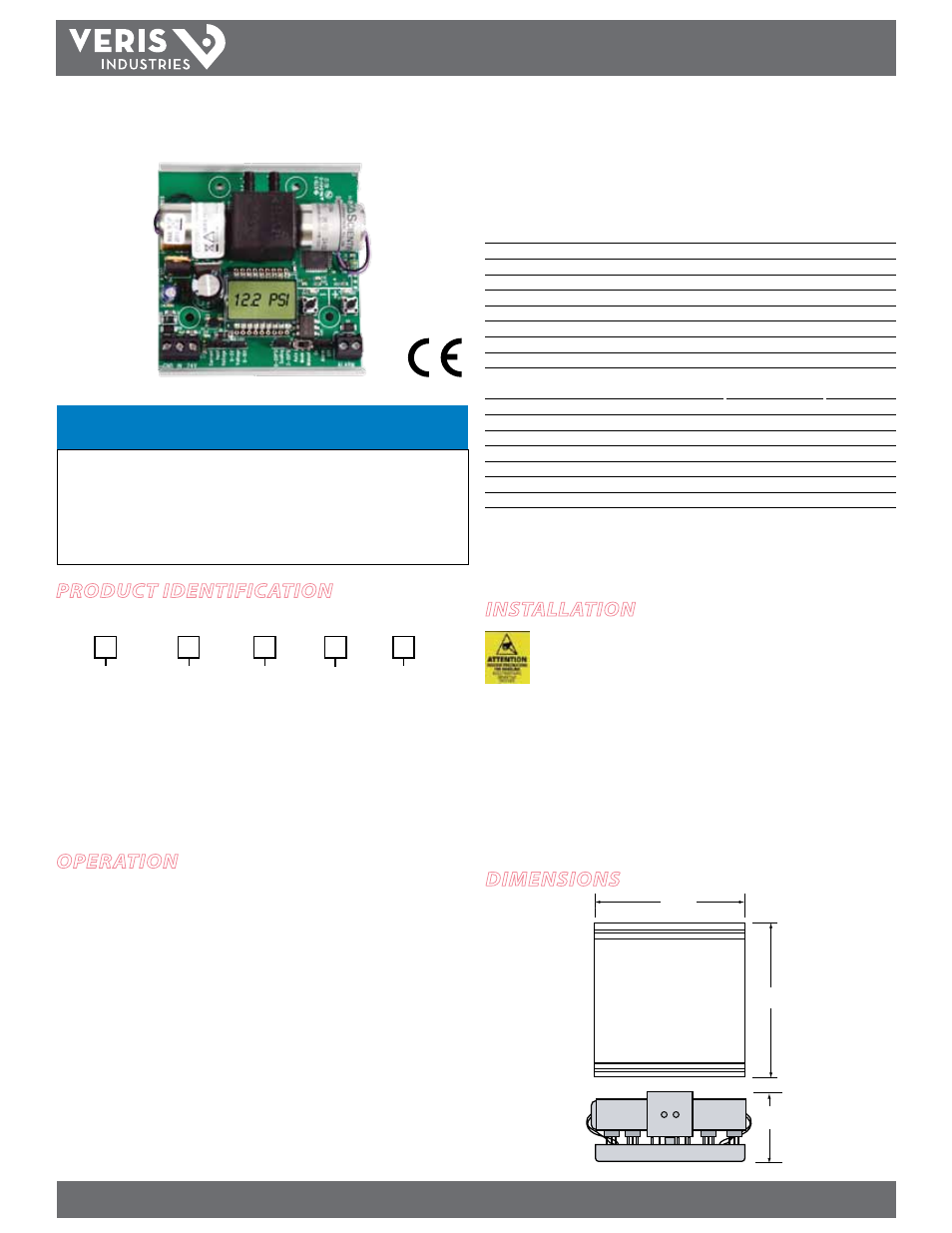

Electropneumatic Transducer

Installer’s Specifications

Power Supply

22-30VDC, 20-30VAC, 47-63 Hz, 150mA max.

Control Input

4-20mA, 0-10V, 0-5V; jumper selectable

Input Impedance

4-20mA, 250 Ω; 0-5/0-10V, 10 kΩ

Manual Override

Jumper selectable mode, digital pushbutton adjust

Alarm Contact

100mA@30VAC/DC (If equiped)

Accuracy

1% full scale; combined linearity, hysteresis, repeatability

Compensated Temperature Range

-4°C to 60°C (25° to 140°F)

Temp Coefficient ±0.05%/°C

Operating Environment

10-90% RH, non-condensing; -4°C to 60°C (25° to 140°F)

SCIM

523 in

3

/min.@45 psi; 8520 cm

3

/[email protected] kPA;

333

in

3

/min@20 psi; 5407 cm

3

/[email protected] kPA

Supply Pressure

45 psig max.

Control Range

0-20 psig or 3-15 psig jumper selectable

Pressure Differential

0.1 psig (supply to branch)

Pressure Indication

Electronic, 3-1/2 digit LCD

Minimum Tubing Length

15 feet

Port Connection

1/8” i.d. poly tubing

Media Connection

Clean dry air or inert gas. Not for use with oxygen service

EMC Conformance: EN 61000-6-3:2007 and A1:2011 Class B, EN 61000-6-1:2007

EMC Special Note: Connect this product to a DC distribution network or an AC/DC power adaptor

with proper surge protection (EN 61000-6-1:2007 specification requirements)

EP2

EP2

Dimensions

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

ProDuct iDentification

installation

Observe precautions for handling static sensitive

devices to avoid damage to the circuitry that

is not covered under the factory warranty.

1. Mount the transducer using the screws provided. Avoid damaging the electronic

components.

2. Wire the transducer and configure the jumpers for desired operation as shown in

the Wiring and Configuration section on the following page.

4. Attach pressure tubing to the hose barbs. Observe MAIN and BRANCH port labels.

Use flexible ¼” O.D. poly tubing for the main and branch pneumatic connections.

Main supply pressure must not exceed 45 psig.

1.9"

(48 mm)

3.3"

(84 mm)

3.5"

(89 mm)

Output

= Selectable

3-15/0-20 psi

US or EU

S = Standard

C = CE (in-

cludes cover

plate.)

Feedback

0 = None

1 = Pressure

Loss Alarm

2 = Manual

Mode Alarm

EP2

Failsafe

0 = None

1 = Vent on

Power Fail

Option

Blank = none

1 = Slide Switch/

Auto/Manual

2 = EP Cover Plate

3 = Slide Switch/

Auto Manual plus

EP cover plate

1

available

oPeration

The EP2 electropneumatic pressure transducer uses micro-controlled poppet valve

technology for highly accurate pressure sensing. The poppet valves consume no air,

eliminating unnecessary air losses in the system and allowing for stable and reliable

operation. The EP2 is comes installed on standard SnapTrack, and an optional cover

is available to protect from dust and other environmental factors. An LCD display and

LED indicators make it easy to read system status at a glance.