Veris Industries Badger 228 SERIES Install User Manual

Page 7

7

Calibration

Badger Meter sensors use unique K

and Offset numbers for calibration.

These numbers are derived from

calibration runs using NIST trace-

able instruments. Using both a K and

an Offset number provides higher

accuracy than using a K (pulse/gal)

factor alone. K and Offset numbers for

each tee configuration are listed in the

following tables.

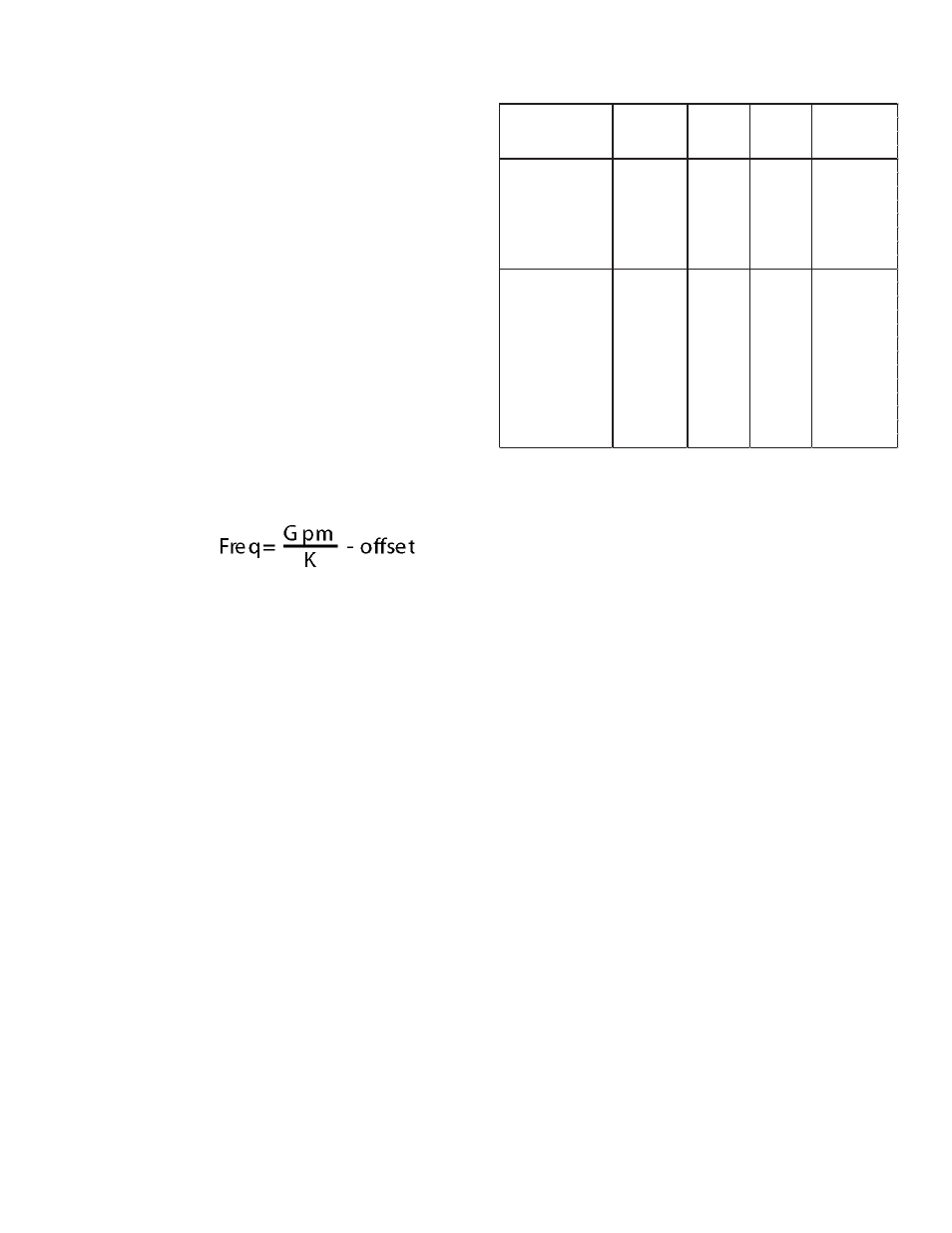

Calibration Tables

The table on page 9 provides cali-

bration and operation data for Data

Industrial Metal Tee Sensors 0.5” to

2.5”.

Column 1

Tee Model Number

Column 2

Apparent I.D. - For use with the Series

900 and the Series 1000

Columns 3 and 4 The K value and Offset values to use

in our frequency equation:

This equation describes the frequency

of the output signal of all Badger

Meter flow sensors. By substituting

the appropriate K and Offset values

from the table, the sensor’s output

frequency can be calculated for each

pipe size. This information is required

when calibrating an output board or

when using the raw sensor data as

direct output to interface with a device

that is not a Badger Meter product.

Column 5

This column indicates the suggested

flow range of each tee sensor. Badger

Meter sensors will operate both

above and below the indicated flow

rates. However, good design practice

dictates the use of this range for best

performance.

Sensors should be sized for flow

rather than pipe size. To prevent

disturbances to the flow profile always

connect the sensor tee to pipe nipples

measuring at least 10 pipe diameters

in length on the up stream (supply)

side and at least 5 pipe diameters in

length on the downstream (delivery)

side before making the transition in

pipe size.

Calibration Table for

Series 228BR, 228CB, 250BR, 228CS, 228SS

Apparent I.D.

Suggested

Model

for Series

K

Offset

Operating

1000, 900

Value

Range

(GPM)

228BR20xx-xxxx

1.99

2.747

0

10-100

228BR25xx-xxxx

2.52

3.741

0.386

16-160

228CB20xx-xxxx

2.07

2.809

0.276

12-120

150 PSI Tee

2.07

400 PSI Tee

2.1

2.604

0.25

12-120

228CB25xx-xxxx

2.51

3.74

0.277

16-160

228CS20xx-xxxx

2.07

2.809

0.276

12-120

228SS20xx-xxxx

1.99

2.747

0

10-100

250BR05xx-xxxx

sch40 PVC

none

0.337379

0.097041

0.8-8

sch80 PVC

none

0.338073

0.134854

0.8-8

sch40 steel

none

0.356212

0.075729

0.8-8

Type L

none

0.350899

-0.321666

0.8-8

250BR07xx-xxxx

sch40 PVC

none

0.436827

0.567915

1-10

sch80 PVC

none

0.43983

0.692372

1-10

sch40 steel

none

0.434836

0.766196

1-10

Type L

none

0.432127

0.619813

1-10

250BR10xx-xxxx

1.05

0.397368

0.261768

2-40

250BR12xx-xxxx

1.38

0.76447

0.16489

3-60

250BR15xx-xxxx

1.61

1.06526

0.0892

4-80

Impeller Assembly and Shaft Replacement

If you are replacing an existing Badger Meter impeller or

shaft and have already calibrated your flow monitor/trans-

mitter, no calibration changes are necessary. For instal-

lation of a new flow monitor or for relocation of a sensor

in a new pipe size, please refer to the calibration instruc-

tions in flow monitor manual.

1) Depressurize pipe from which sensor is to be re-

moved.

2) If insert style (Models 228xx) remove the three lock

nuts that secure the positioning collar to the threaded

rods of metal sensor.

nOTE: Before removing lock nuts, record the dimen-

sion from top of 2” NPT adapter to the bottom of the

positioning collar. This dimension will be required

later to reinstall. For Series 250BR style remove the

clevis pin.

3) Remove the sensor from the hex adapter or the tee.

4) Note the impeller blade orientation relative to flow ar-

rows and the alignment hole in metal sensors beside

one of the sight holes. In order to maintain proper

calibration, the impeller will have to be reinstalled in

the same manner with the impeller blades pointing

toward the small alignment hole, and into the flow

direction as indicated by the flow arrows.

5) To remove the old impeller blade assembly, push the

old shaft out of the sleeve with the new shaft (or small

diameter rod) just far enough to grab the end with a

pair of pliers and pull the shaft completely out. The

impeller assembly will now be free, and will drop out.

6) Inspect the shaft and bearings for wear, and replace

as necessary.

7) Refer to Figure 1. To reinstall, position the impeller in

the cavity oriented as in Step 4 so that the impeller

blades point into the flow direction and toward the

small alignment hole located beside one of the sight-