Caution, Installation guide, Operation – Veris Industries H614 Install User Manual

Page 2: Status leds, Troubleshooting, Dimensions, H614, For load currents less than sensor minimum rating

Z206036-0A

PAGE 2

©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

09121

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

H614

OPERATION

The H614 is a current-sensitive switching device designed for use with VFD systems.

It is equipped with an auto calibration feature that allows the device to distinguish

between a reduced amp draw due to normal changes in frequency and an abnormal

drop due to belt loss or other mechanical failures.

The H614 is designed for HVAC fan and blower systems, as well as some pumping

systems involving consistent viscosity liquids. If an H614 is installed on one phase of

the VFD, it detects changes in that phase that result from the VFD compensating for

changes elsewhere in the system. Alternatively, for increased sensitivity, H614s can

be used on all three phases for immediate detection of amperage changes anywhere

in the system.

A change from the normal amperage and frequency profile in the monitored

conductor will cause the resistance of the FET status output to change state, similar

to the action of a mechanical switch. The status output is suitable for connection to

building controllers or other appropriate data acquisition equipment operating at up

to 30 volts. The H614 requires no external power supply to generate its output.

Performance of the H614 can be optimized through an optional step. When the H614

is first powered and is in Learn Mode, manually cycle through each 5 Hz frequency

band, allowing the VFD to remain at each band for 15 seconds.

NOTES

CAUTION

RISK OF EQUIPMENT DAMAGE

• Derate the product’s maximum current for the number of turns

through the sensing window using the following formula.

Rated Max. Amps ÷ Number of Turns = Max. monitored Amps

e.g. : 100A ÷ 4 Turns = 25 Amps max. in monitored conductor

• Failure to follow these instructions can result in overheating

and permanent equipment damage.

For load currents less than sensor minimum

rating:

Wrap the monitored conductor through the

center window and around the sensor body to

produce multiple turns. This increases the current

measured by the transducer.

4x

0.5A

VERIS INDUSTRIES

Portland, Oregon 97223

1-800-354-85

56

Hawkeye

®

< 1.5 A (Sensor Min.)

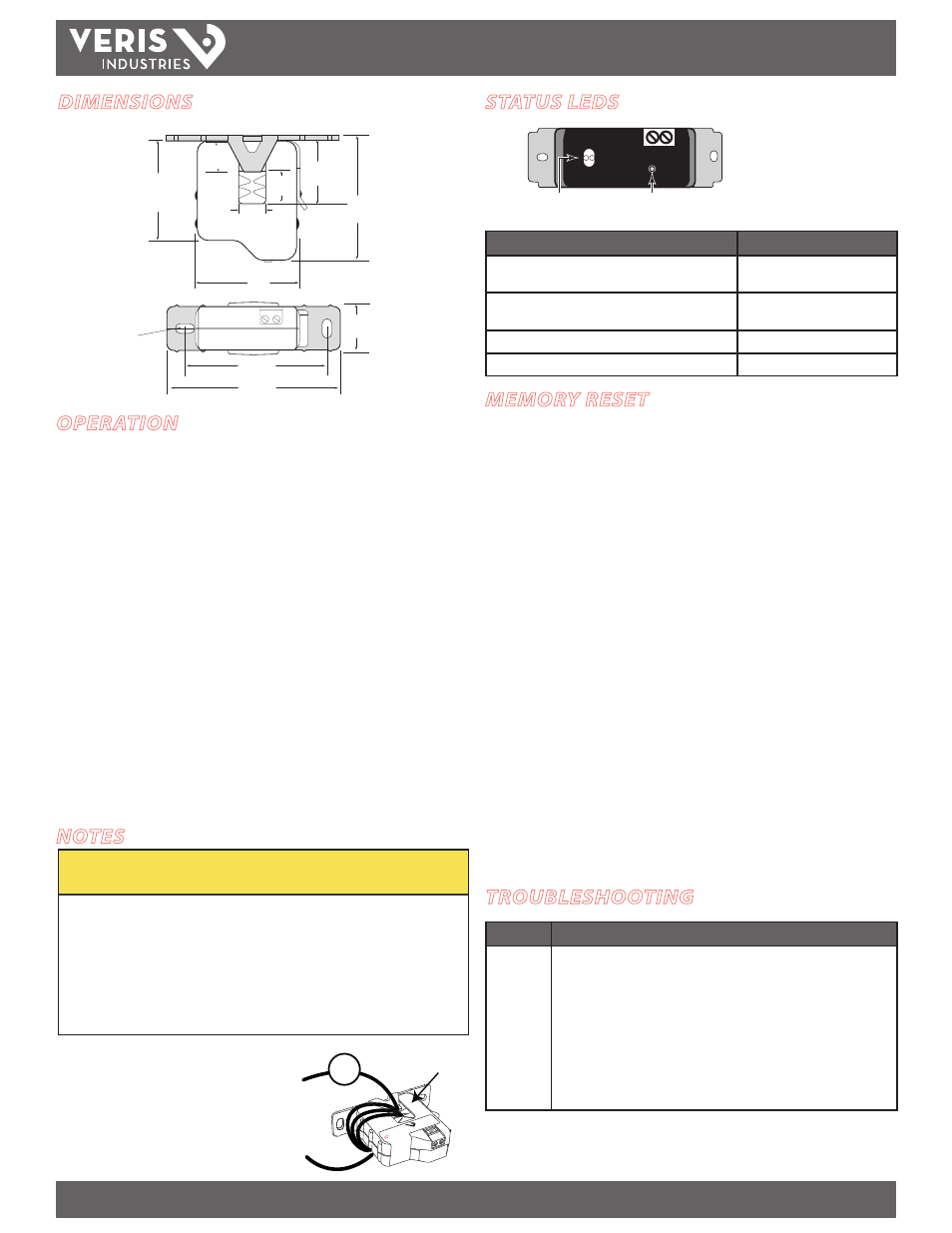

STATUS LEDS

STATUS

RESET

Memory Reset Button

(can be used whether unit is powered or unpowered)

Status LEDs

(left LED = Green; right LED = Red)

Sensor Mode

Status LED Blink Pattern

Learning Mode (first 15 sec of operation after frequency

stabilizes)

Alternating Red/Green (1 per sec.)

On/Off Status only; Learn mode incomplete. VFD system

does not meet abnormal condition detection criteria

Green blink (5 times per sec. after

15 sec of stable frequency)

Status OK

Green blink (1 per sec.)

Alarm

Red blink (1 per sec.)

MEMORY RESET

During setup, the H614 automatically determines the normal amperage and

frequency profile and stores it in nonvolatile memory. The H614 requires a Memory

Reset to clear the nonvolatile memory if any of the following conditions occur:

• The sensor is reinstalled on a different motor.

• The motor is re-sheaved.

• The system is air balanced or air duct restrictions change

• The motor load changes significantly.

To reset the H614:

1. Establish normal operating conditions for the monitored conductor (e.g. clean air

filters, close duct access doors).

2. The Reset switching button has two positions, in and out. Push the button until

there is a noticable click to change the position of this switch. This causes a change

of state, which triggers the Reset function. The nonvolatile memory is erased and

the H614 will enter the Learning mode (LEDs blink red/green) to learn the new

amperage profile of the monitored conductor.

Note: The Reset function can be performed even if the H614 is not

installed on a conductor. Pushing the button (changing the state) will

clear the nonvolatile memory at the next power-up.

Note: For normal operation, this button can be in either in or out

position.

TROUBLESHOOTING

Problem

Solution

No LED or

Incomplete

Learn mode

• Check for amperage in monitored conductor (>1.5 A).

• Check that amperage in the monitored conductor does not exceed sensor

max (150 A).

• Ensure that no more than 30 VAC/DC or 1.0A has passed through the contact.

Voltages or currents above these levels will damage the unit.

• Ensure that sensor core mating surfaces are clean and that the core clamp is

completely closed.

• Ensure that the sensor is operating within specified temperature range.

• Ensure that the sensor has completed Learn mode. If it has not, check circuit

parameters and compliance.

DIMENSIONS

2.5" *

(64 mm)

2.1"

(54 mm)

3.5"

(89 mm)

2.9"

(74 mm)

0.4” x 0.2”

(10 mm x 5 mm)

Slot (2x)

1.2"

(31 mm)

Removable Mounting Bracket

0.7"

(18 mm)

0.5"

(13 mm)

2.1"

(54 mm)

1.0" *

(26 mm)

0.6"

(16 mm)