Calibration troubleshooting, Installation guide current monitoring h906 – Veris Industries H906 Install User Manual

Page 4

Z201573-0D

Page 4 of 4

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected] 07132

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Installation Guide

Current Monitoring

H906

TM

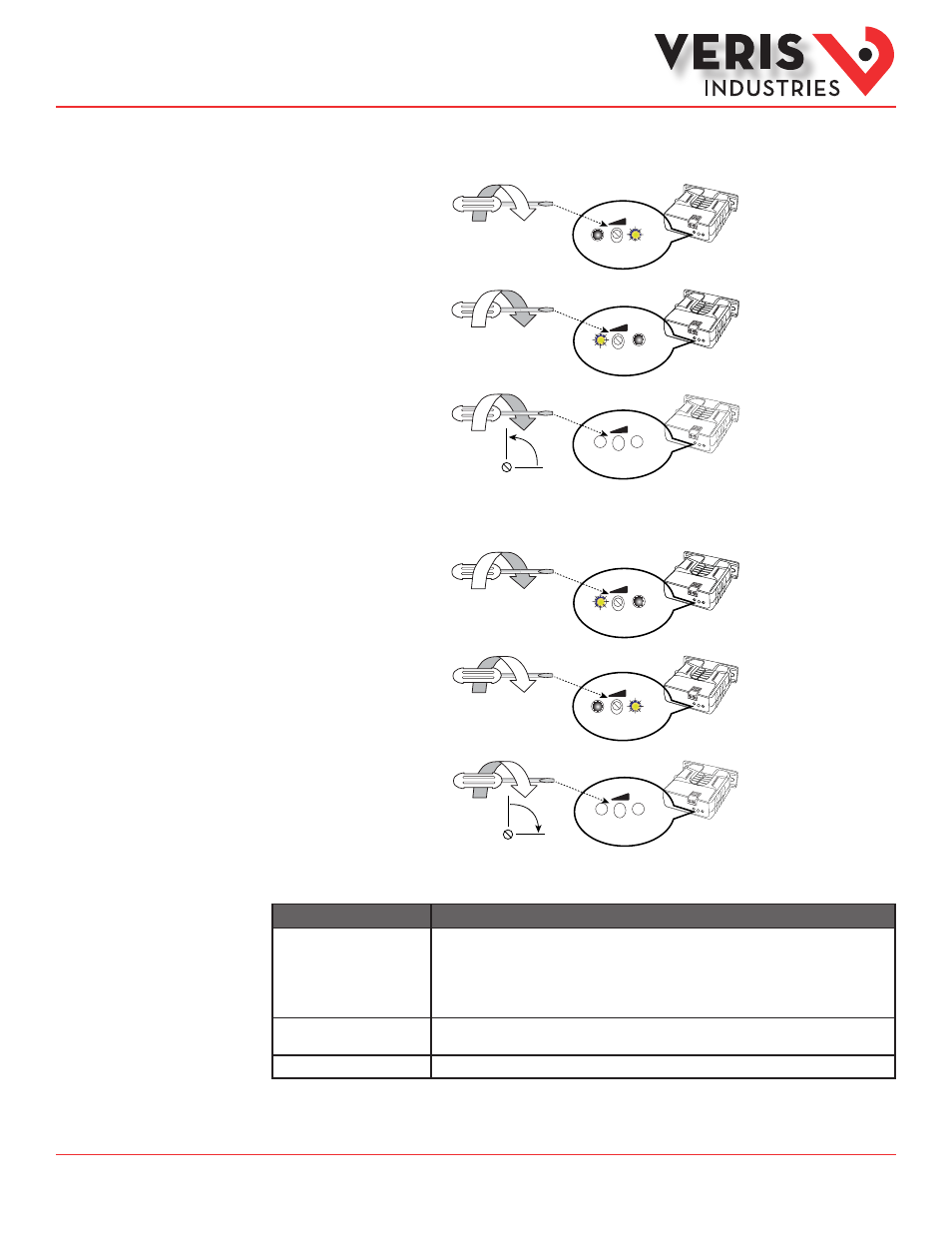

Before beginning calibration, establish normal load conditions. Then choose either A or B below.

A. To monitor under-current (belt loss, coupling shear, status)

1. Turn setpoint screw clockwise

until Status Open LED turns

on.

Status

Closed

Status

Open

Setpoint

2. Slowly turn the screw counter

clockwise until the Status

Closed LED turns on.

Status

Closed

Status

Open

Setpoint

3. Turn the screw an additional

¼ turn counter clockwise for

operational margin.

¼

Status

Closed

Status

Open

Setpoint

B. To monitor over-current (mechanical problems, seized impeller)

1. Turn setpoint screw counter

clockwise until Status Closed

LED turns on.

Status

Closed

Status

Open

Setpoint

2. Slowly turn the setpoint screw

clockwise until the Status

Open LED just turns on.

Status

Closed

Status

Open

Setpoint

3. Turn the setpoint screw an

additional ¼ turn clockwise

for operational margin.

¼

Status

Closed

Status

Open

Setpoint

Calibration

Troubleshooting

Problem

Solution

No Reading at Controller

• Check sensor calibration (see above)

• Check for control voltage at sensor (5VDC

• Verify correct polarity

• Assure that sensor core mating surfaces are clean and that the core clamp is completely closed

Setpoint screw has no stops

The setpoint screw has a slip-clutch at both ends of its travel to avoid damage. Twenty turns CCW will

reset the sensor to be most sensitive. Repeat calibration above.

Both LEDs are lit

Setpoint screw is too far clockwise. See solution above.