Veris Industries H614 Datasheet User Manual

Vfd current switch auto calibration, Automatically learns load at initial power-up, H614

current monit

oring

VERIS INDUSTRIES

800.354.8556

+1 503.598.4564

www.veris.com

SPECIFICATIONS

Sensor Power

Induced from monitored conductor

Response Time

1 sec.

Learn Time

15 sec. learn period after frequency stabilizes

Frequency Range

12 to 115 Hz

Temperature Range

-15° to 60° C (5° to 140°F)

Humidity Range

10-90% RH non-condensing

Alarm Limits

±

20% of learned current in every 5 Hz freq. band

NORMAL-to-ALARM Status Output Delay

~7 second max.

ALARM-to-NORMAL Status Output Delay

1 sec. nominal*

Off Delay

<30 sec. nominal

Contact Ratings

30VAC/DC, 1A

Insulation Class

600VAC (UL); 300VAC RMS (CE)

Terminal Block Maximum Wire Size

14 AWG

Terminal Block Torque (nominal)

3.54 to 4.43 in-lbs (0.4 to 0.5 N-m)

Agency Approvals

UL508 open device, CE: EN61010-1:2001-02, CAT III, pollution degree 2

*If the H614 experiences a momentary loss of power, the Alarm-to-Normal output delay may exceed 1 sec.

Specification Note: For CE compliance, conductor shall be insulated according to IEC 61010-1:2001.

The product design provides for basic insulation only. Use wire with minimum 75°C rated insulation. Do not use the LED status indicators as evidence of applied voltage.

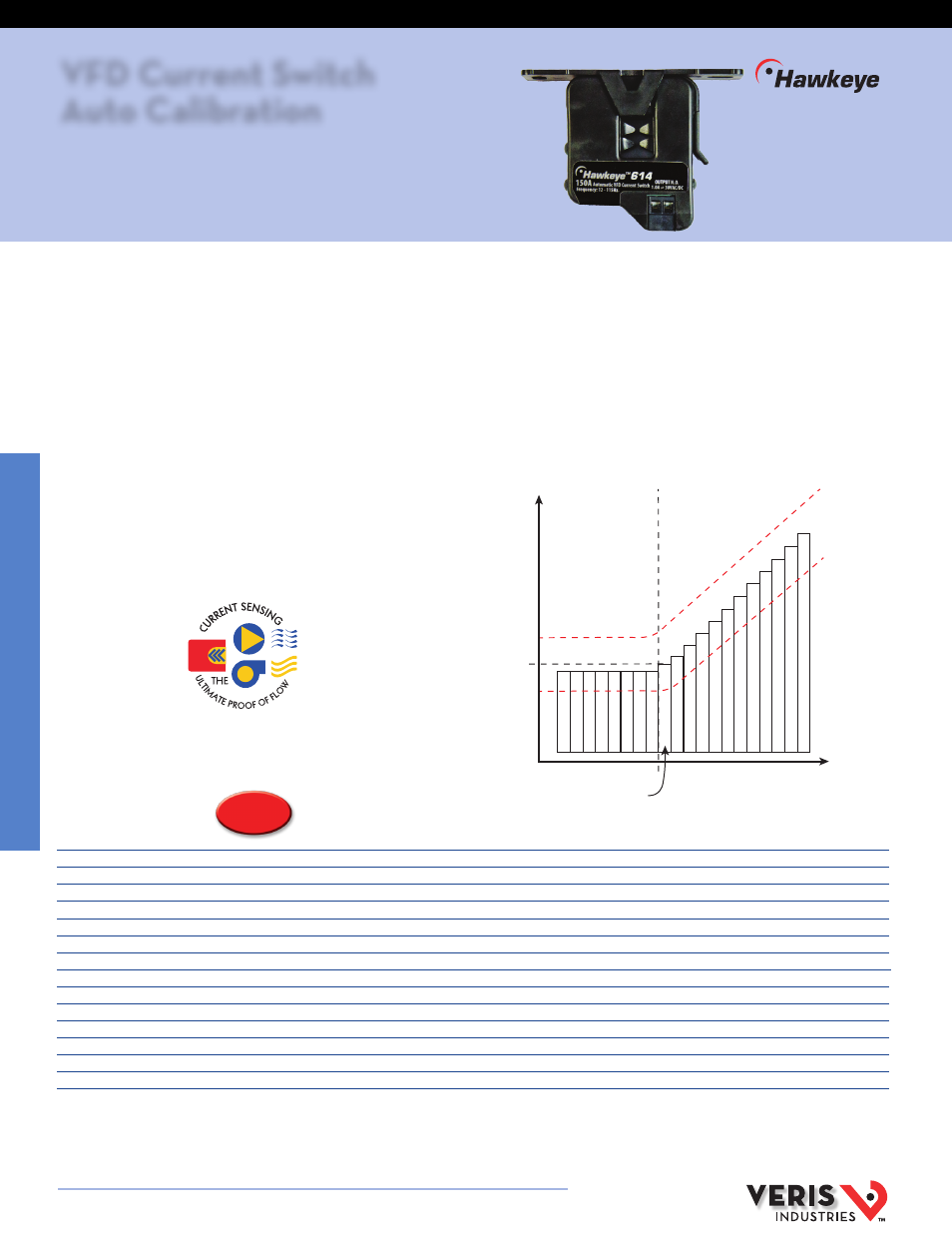

This sensor detects abnormal operation by looking for sudden changes in current across the entire frequency range. In Learn mode, the sensor calculates a margin 20% above and 20% below the learned frequency curve.

An abnormal condition in the circuit is one that falls outside this margin.

DESCRIPTION

The Hawkeye H614 is a microprocessor based, self-learning, self-calibrating current-

sensitive switching device designed for use with VFD systems. It is equipped with

an auto calibration feature that allows the device to distinguish between a reduced

amp draw due to normal changes in frequency (e.g., gradual filter restrictions) and

a sudden drop (e.g., belt loss or other mechanical failure). At initial power-up, the

H614 automatically learns the average current on the line with no action required

by the installer. Once a current is learned, the switch monitors for changes in current

greater than ±20% of the learned load.

APPLICATIONS

●

Detecting belt loss, coupling shear, and mechanical failure

●

HVAC fan/blower motor failure

●

Detecting unauthorized duct access

FEATURES

●

Microcontroller based learning technology...automatically learns load upon

initial power-up...eliminates labor associated with calibration

●

Automatic trip point (1.5 to 150 Amps, 12 to 115 Hz)...reduced errors

●

Monitors current for both under- and over-load in one package

●

Small size fits easily inside small starter enclosures...saves space

●

100% solid state...no moving parts to fail

●

Removable mounting bracket for installation flexibility

●

5-year warranty

Automatically Learns Load

At Initial Power-Up

VFD Current Switch

Auto Calibration

Maximize Reliability

Minimize Installed Cost

Year

Warranty

5

H614

PRODUCT FUNCTIONS

H614

HQ0002067.A 09121

Learned C

urr

en

t

Frequency

Band 1 Band 2 Band 3 Band 4 Band 5 Band 6 Band 7 Band 8 B

and 9 Band 10 B

and 11 Band 12 B

and 13 Band 14

Band 15 B

and 16 B

and 17 Band 18 B

and 19 Band 20

+20%

-20%

Constant Torque

Constant Power

Elbow

Current

Elbow

Band

TM