Installation, Installation guide current monitoring h931, Caution – Veris Industries H931 Install User Manual

Page 2

Z201168-0E

Page 2 of 4

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected] 08131

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Installation Guide

Current Monitoring

H931

TM

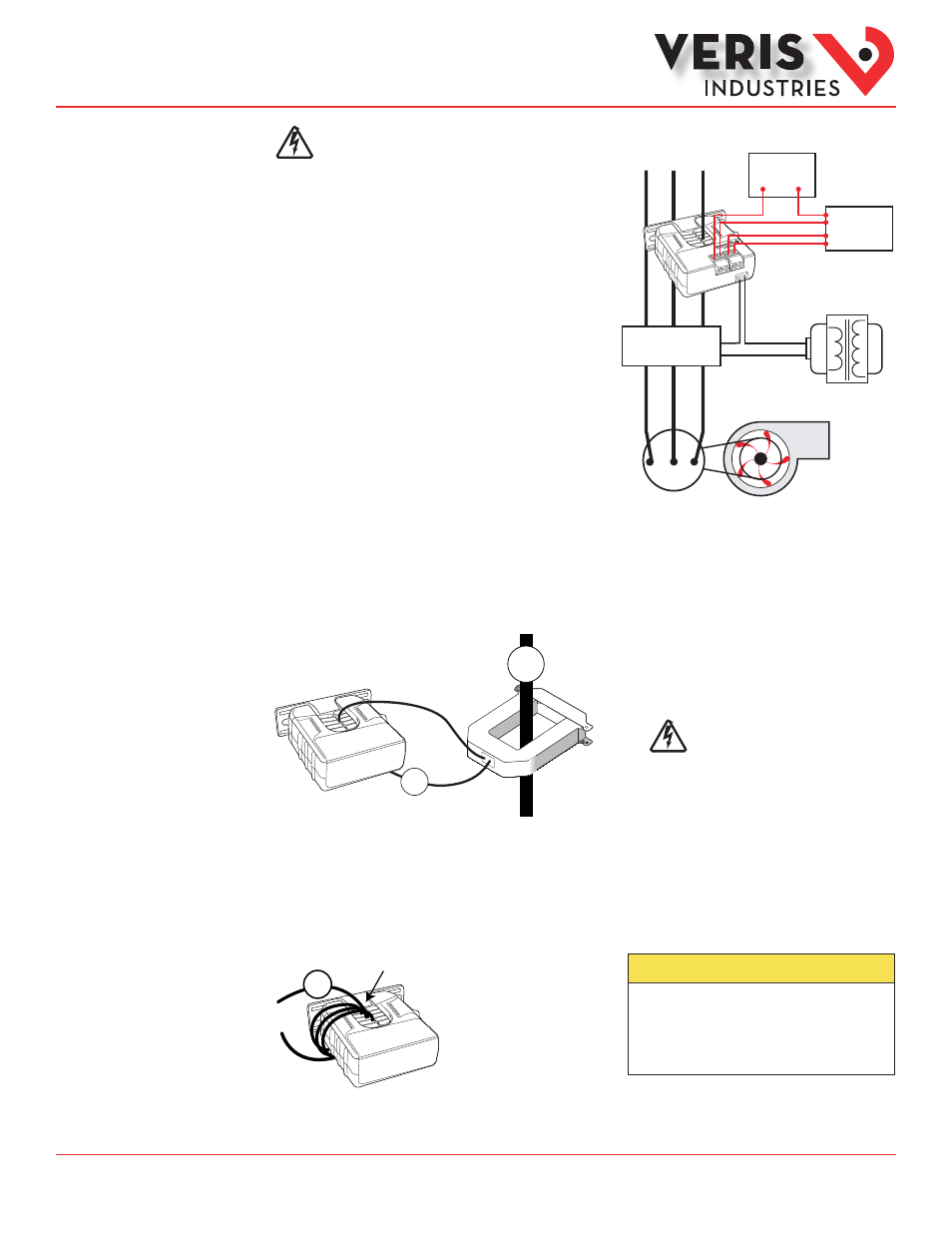

Disconnect and lock out power to the enclosure containing the conductor to be

monitored.

1. Locate a mounting surface for the removable mounting bracket

that will allow the monitored conductor to pass through the center

window when it is installed and that will keep the product at least

½” (13 mm) from any uninsulated conductors. Determine cable

routing for the controller connection, allowing wiring to reach the

mounting location. If using with a variable frequency drive, then

mount the sensor on the line side.

2. Drill holes to mount the bracket to the chosen surface using the

included screws.

3. Set the desired amperage range (30, 60, or 120 Amps).

4. Wire the output connections between the sensor and the controller

(4-20mA).

5. Snap the sensor over the wire to be monitored and clip the assembly

to the mounting bracket.

6. Scale the controller software to match the sensor’s output.

7. Secure the enclosure and reconnect power.

Installation

Fan or Pump

CONTROLLER

Motor

CONTACTOR

AI

(4-20mA)

DO

(Relay Coil)

CONTROL POWER

12-30 VDC

Power Source

Notes

For load currents greater than sensor maximum rating:

Use a 5 Amp (H68xx series) current transformer (CT) as shown. This technique can be combined with wrapping (see below) to add

range for a low current load on a high current source.

DANGER: 5A CTs can present

hazardous voltages. Install

CTs in accordance with

manufacturer's instructions.

Terminate the CT secondary

before applying current.

CAUTION

RISK OF EQUIPMENT DAMAGE

• Derate the product’s maximum current for the number of turns

through the sensing window using the following formula.

Rated Max. Amps ÷ Number of Turns = Max. monitored Amps

e.g. : 100A ÷ 4 Turns = 25 Amps max. in monitored conductor

• Failure to follow these instructions can result in overheating

and permanent equipment damage.

4x

1A

H68xx-5A CT

240A

300A:

5A

4A

>120 A (sensor max.)

< 1.5 A (Sensor Min.)

For load currents less than sensor minimum rating:

Wrap the monitored conductor through the center window and around the sensor body to produce multiple turns. This increases

the current measured by the transducer. Program the controller to account for the extra turns (e.g., if four turns pass through the

sensor (as shown), divide the normal reading by 4).