Spicer Single Speed Axle - Service Manual User Manual

Page 23

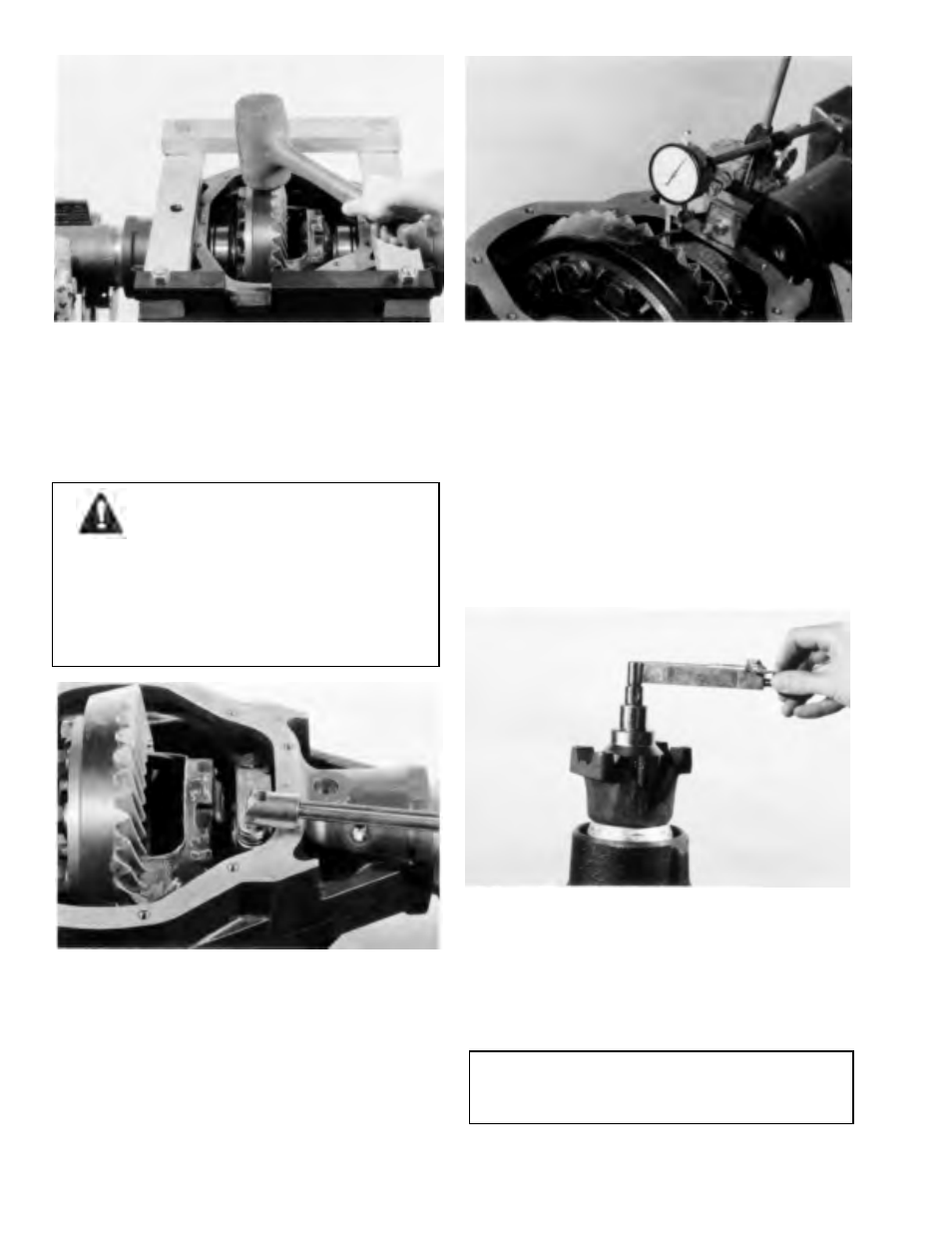

Figure 3-46

Step (47) Assemble differential bearing cups to differential

bearing cones. Install differential assembly into carrier. Use

a rawhide or plastic hammer to seat differential assembly

into cross bores of carrier. Care should be taken to avoid

nicking the teeth of the ring gear and pinion during

assembly. Remove spreader.

WARNING: When differential assembly is

installed into carrier, use care to avoid

pinching hand or fingers between

differential bearing cup and carrier

housing.

Gear teeth may have sharp edges. When

handling gear, use care to avoid cutting

hands.

Figure 3-47

Step (48) Install bearing caps. Make sure the letters

stamped on the caps correspond with those on the carrier.

Torque bearing cap screws to specification.

TOOL: Torque Wrench

3-14

Figure 3-48

Step (49) Check ring gear and pinion backlash in three

equally spaced points with dial indicator as shown.

Backlash should be within specification and cannot vary

more than .002 (-05 mm) between points checked.

TOOL: C-3339 Dial Indicator Set

High backlash is corrected by moving the ring

gear closer to the pinion.

Low backlash is corrected by moving the ring gear

away from the pinion.

These corrections are made by switching shims

from one side of the differential case to the other.

Figure 3-49

Step (50) Using an in. lb. torque e wrench as shown, rotate

pinion and differential assembly, Torque reading should

be within specifi ication. If preload is to high, remove an

equal amount of shims from both sides of the differential

case hubs. If preload is to low, add an equal amount of

shims to both sides of differential case hubs.

NOTE

If shims are added to one side only, it will affect

backlash reading.