Ring gear removal, Servicing standard differential case assembly, Case disassembly – Spicer Single Speed Axle - Service Manual User Manual

Page 11

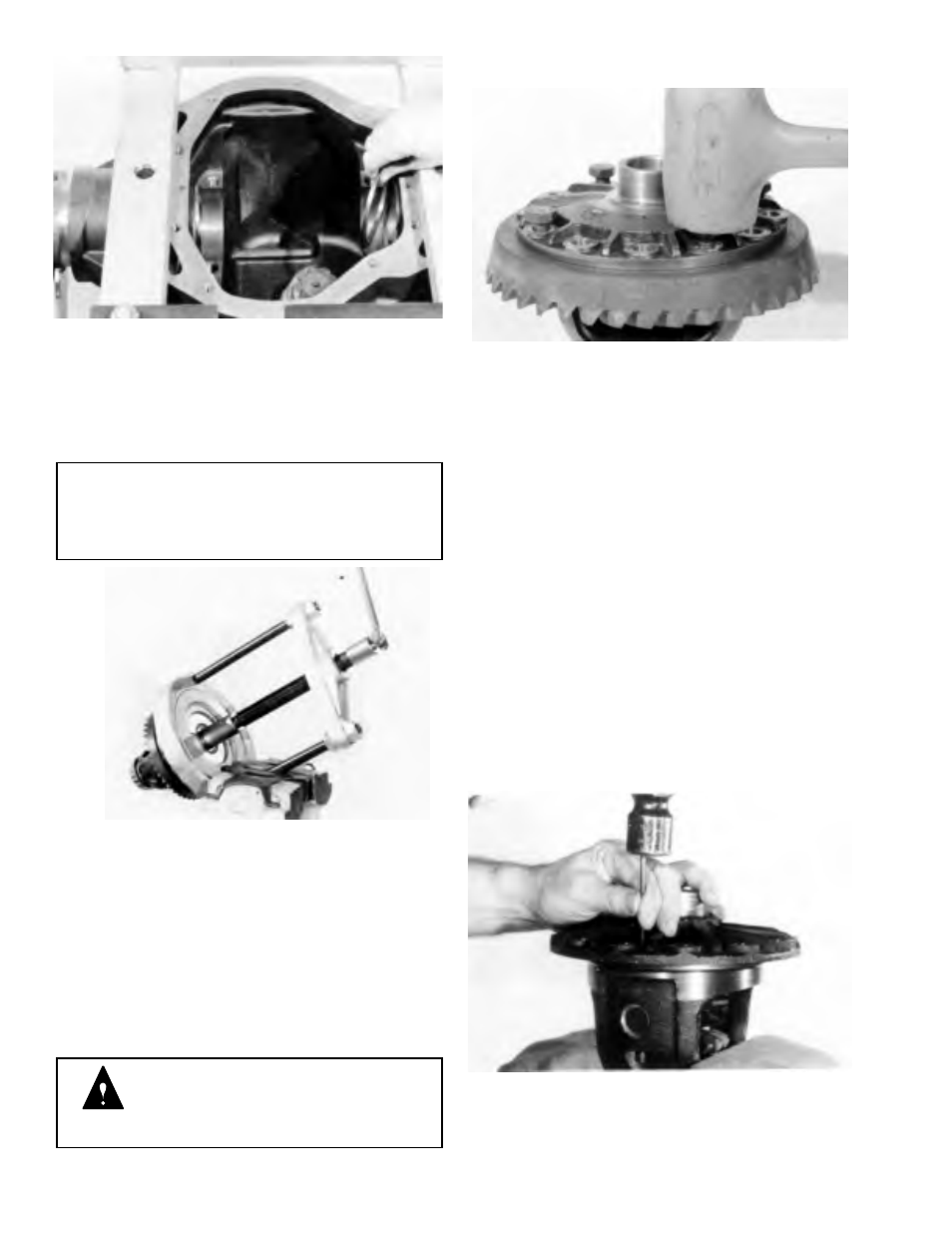

Figure 3-4

Step (5) Note the differential bearing outboard spacers

located on each side of the differential bearing bore.

Remove and tag which side they were removed from. Ring

gear side or opposite side. They will be reused during

assembly, unless damaged or worn.

NOTE

Check outboard spacers for damage. (e.g. caused

by worn bearings). If damaged, they should be

replaced with new ones at time of reassembly.

Figure 3-5

Step (6) Remove differential bearing cones with a puller

as shown. Tag cones indicating from which side they were

removed from.

TOOL:

DD-914 Press

DD-914-99 Adapters

DD-914-8 Adapter Ring

DD-914-7 Extension

DD-914-42 Button

WARNING: When pulling bearings, do

not allow differential assembly to fall. It

can strike legs or feet and may cause

serious injury.

RING GEAR REMOVAL

Figure 3-6

Step (7) Place differential case in vise or suitable holding

fixture. Remove ring gear screws. Leave 4 screws loosely

assembled 90 degrees apart. Place assembly on a solid

bench. Tap screws alternately and evenly to free ring gear

from differential case. Remove screws and ring gear.

Discard ring gear screws. Ring gear screws are to be

replaced with new ones at time of reassembly.

SERVICING STANDARD

DIFFERENTIAL CASE ASSEMBLY

The differential assembly may be serviced at this time, if

required. If differential case, side gears and pinion mate

gears are useable and do not require servicing, proceed to

DRIVE PINION REMOVAL.

CASE DISASSEMBLY

Figure 3-7

Step (8) Remove roll pin with a small drift.

3-2