Spicer Single Speed Axle - Service Manual User Manual

Page 21

3-12

face of the case is free of nicks or burrs. Assemble ring

gear to case. Line up holes of the ring gear with those of

the case. Use new ring gear screws. Draw up screws

alternately and evenly. Torque ring gear screws to

specification.

TOOL: Torque Wrench

Figure 3-42

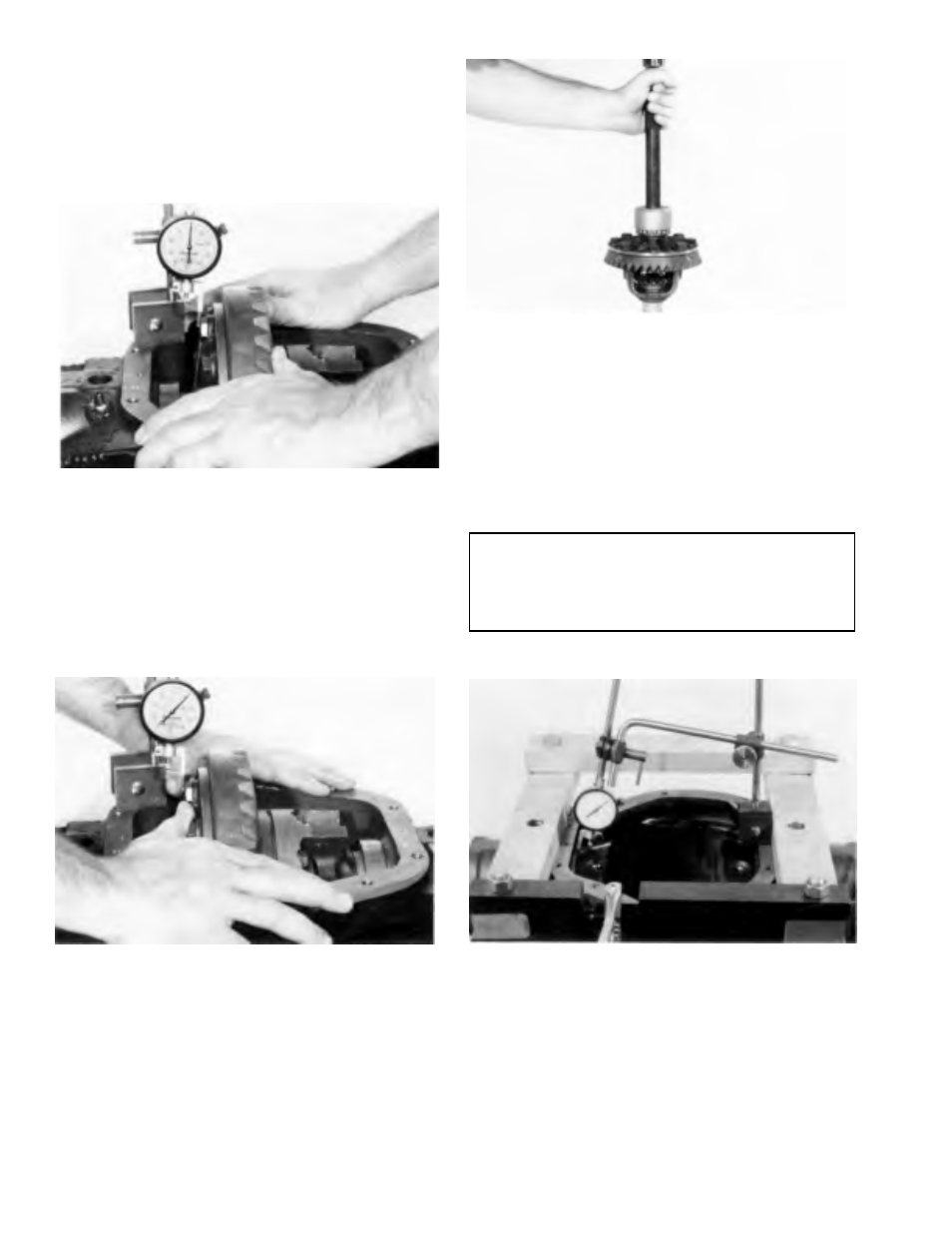

Step (43) Assemble master differential bearings onto case

hubs. Place differential assembly into housing. Set up dial

indicator as shown. Locate tip of indicator on flat surface

of one of the ring gear screws. Force the differential case

assembly (ring gear) away from the pinion gear. With force

still applied to the differential case, set indicator at zero

“0”.

TOOL: C-3339 Dial Indicator Set

Figure 3-43

Step (44) Force the differential case assembly and ring

gear into mesh with the pinion gear. Rock ring gear to allow

the teeth of the gear to mesh. Repeat until the same reading

is obtained each time. Record this reading on the

worksheet, page 313. This reading will be measurement

“B”. Remove indicator and differential case assembly from

the carrier. Remove master differential bearings from the

differential case. Refer to the worksheet for calculating

ring gear backlash and differential bearing preload shims,

page 3-13.

Figure 3-44

Step (45) Assemble the required amount of shims onto

hub (ring gear side) and opposite side as determined using

the worksheet. Place bearing cone on hub of case. Use

bearing installer to seat bearing cone as shown.

TOOL:

C- 1490 Installer

C-4171 Handle

DD-914-42 Button

NOTE

Button is used to raise case from bench to protect

bearing cone cage from being damaged when

installing opposite bearing cone.

Figure 3-45

Step (46) Install spreader and indicator as shown. DO NOT

SPREAD CARRIER OVER .015 (.38 mm). Remove indicator.

TOOL: W- 129 B Differential Spreader

C-3339 Dial Indicator Set