Spicer Single Speed Axle - Service Manual User Manual

Page 15

On the button end of each pinion, there is etched

a plus (+) number, a minus (-) number, or a zero (0)

which indicates the best running position for each par-

ticular gear set. This dimension is controlled by the

shimming behind the inner pinion bearing cup.

For example: If a pinion is etched a plus +3 (m+8),

this pinion would require .003 (.08 mm) less shims

than a pinion etched “0”. This means by removing

shims, the mounting distance of the pinion is in-

creased to 3.503 (88.98 mm), which is just what a +3

(m+8) indicates. Or if a pinion is etched -3 (m-8), we

would want to add .003" (.08 mm) more shims than

would be required if the pinion were etched “0”. By

adding .003 (08 mm) shims, the mounting distance

of the pinion was decreased to 3.497 inches (88.82

mm) which is just what a -3 (m-8) indicates.

If the old ring and pinion set is to be reused, mea-

sure the old shim pack and build a new shim pack to

this same dimension. If a baffle is used in the axle

assembly, it is considered as part of the shim pack.

To change the pinion adjustments, use different

combination of the pinion shims which come in

different thicknesses.

NOTE

If baffle or slinger is bent or mutilated, it should be

replaced.

Measure each shim separately with a microme-

ter and add together to get total shim pack thickness

from the original build-up.

If a new gear set is being used, notice the (+) or

(-) etching on both the old and new pinion and adjust

the thickness of the new shim pack to compensate

for the differences of these two figures.

For example: If the old pinion reads +2 (m+5) and

the new pinion is -2 (m-5), add .004" (. 10 mm) shims

to the original shim pack.

Figure 3-19 (Pinion Setting Chart - English U.S.

Standard)

Figure 3-20 (Pinion Setting Chart - Metric)

If metric, pinion will be etched (m+ some num-

ber). Example (m+5). Use these charts as a guideline

to set pinion.

ESTABLISHING PINION GEAR

DEPTH USING SERVICE TOOL

GAGES.

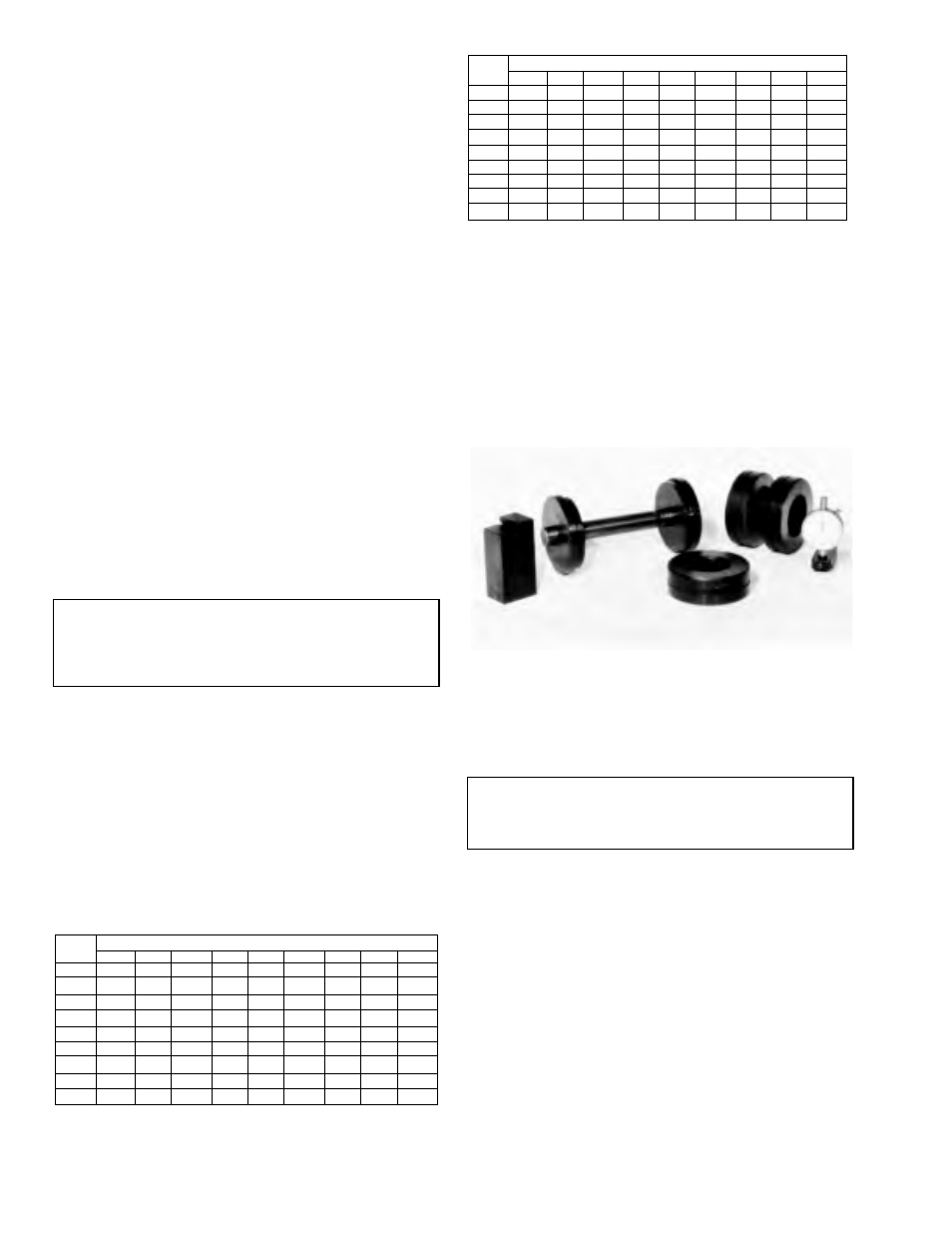

Figure 3-21

View of master pinion bearing, pinion height

block, scooter gage, cross arbor, arbor discs and

master differential bearings.

NOTE

Make sure that all carrier bores are free from all

nicks, dirt or any other contamination.

3-6

-10

-8

-5

-3

0

+3

+5

+8

+10

+10

+.20

+.18

+.15

+.13

+.10

+.08

+.05

+.03

0

+8

+.18

+.15

+.13

+.10

+.08

+.05

+.03

0

-.03

+5

+.15

+.13

+.10

+.08

+.05

+.03

0

-.03

-.05

+3

+.13

+.10

+.08

+.05

+.03

0

-.03

-.05

-.08

0

+.10

+.08

+.05

+.03

0

-.03

-.05

-.08

-.10

-3

+.08

+.05

+.03

0

-.03

-.05

-.08

-.10

-.13

-5

+.05

+.03

0

-.03

-.05

-.08

-.10

-.13

-.15

-5

+.03

0

-.03

-.05

-.08

-.10

-.13

-.15

-.18

-10

0

-.03

-.05

-.08

-.10

-.13

-.15

-.18

-.20

New Pinion Marking

Old Pinion

Marking

-4

-3

-2

-1

0

+1

+2

+3

+4

+4

+0.008

+0.007

+0.006

+0.005

+0.004

+0.003

+0.002

+0.001

0

+3

+0.007

+0.006

+0.005

+0.004

+0.003

+0.002

+0.001

0

-.0.001

+2

+0.006

+0.005

+0.004

+0.003

+0.002

+0.001

0

-.0.001

-0.002

+1

+0.005

+0.004

+0.003

+0.002

+0.001

0

-.0.001

-0.002

-0.003

0

+0.004

+0.003

+0.002

+0.001

0

-.0.001

-0.002

-0.003

-0.004

-1

+0.003

+0.002

+0.001

0

-.0.001

-0.002

-0.003

-0.004

-0.005

-2

+0.002

+0.001

0

-.0.001

-0.002

-0.003

-0.004

-0.005

-0.006

-3

+0.001

0

-.0.001

-0.002

-0.003

-0.004

-0.005

-0.006

-0.007

-4

0

-.0.001

-0.002

-0.003

-0.004

-0.005

-0.006

-0.007

-0.008

New Pinion Marking

Old Pinion

Marking