Ring & pinion gear assembly theory – Spicer Single Speed Axle - Service Manual User Manual

Page 14

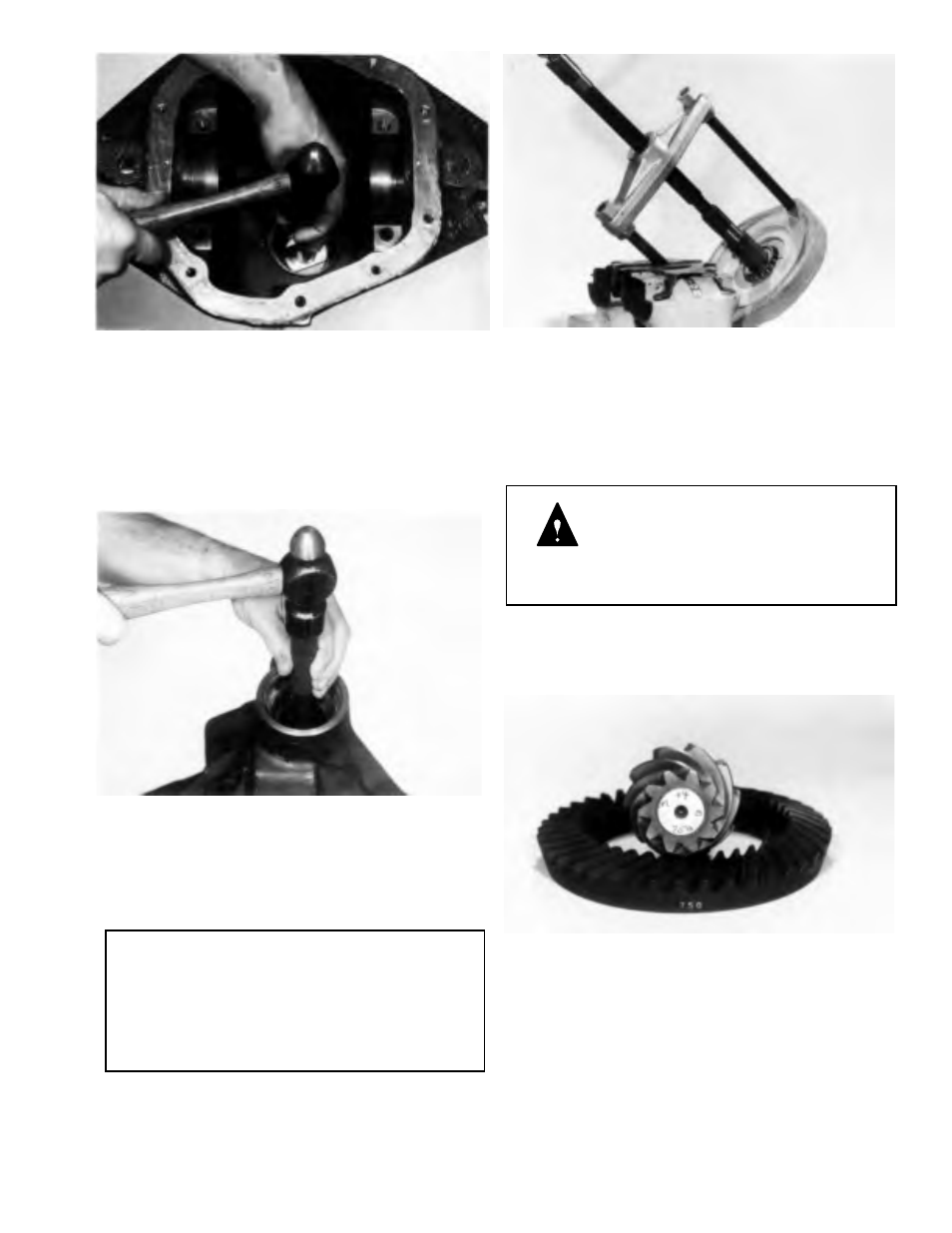

Figure 3-15

Step (20) Turn nose of carrier down. Remove outer pinion

bearing cup. Locate driver on back edge of cup; drive cup

out of carrier. CAUTION: DO NOT NICK CARRIER BORE.

TOOL:

D-159 Pinion Bearing Cup Remover

C-4171 Handle

Figure 3-16

Step (21) Remove the inner bearing cup with tools as shown.

TOOL:

C-4307 Bearing Cup Remover

C-4171 Handle

NOTE:

Shims are located between the bearing cup and

carrier bore and may also include an oil baffle,

depending upon the application. If shims and baffle

are bent or nicked, they should be replaced at time

of assembly.

Figure 3-1 7

Step (22) Remove pinion bearing with tools as shown.

TOOL:

DD-914-P Press

DD-914-8 Adapter Ring

DD-914-95 Adapters

WARNING: Do not allow gear to fall. It can

strike legs or feet and may cause serious

injury. Gear teeth may have sharp edges.

When handling, use care to avoid cutting

hands.

RING & PINION GEAR

ASSEMBLY THEORY

Figure 3-18 (View of ring 81 pinion set)

Step (23) Ring gears and pinions are supplied in matched

sets only. Matching numbers on both the pinion and ring

gear are etched for verification. If a new gear set is being

used, verify the numbers of each pinion and ring gear before

proceeding with assembly.

The nominal distance from the centerline of the ring

gear to the button end of the pinion for the Model 80 axle

is 3.500 (88.9 mm).

3-5