Assembly of differential – Spicer Single Speed Axle - Service Manual User Manual

Page 20

3-11

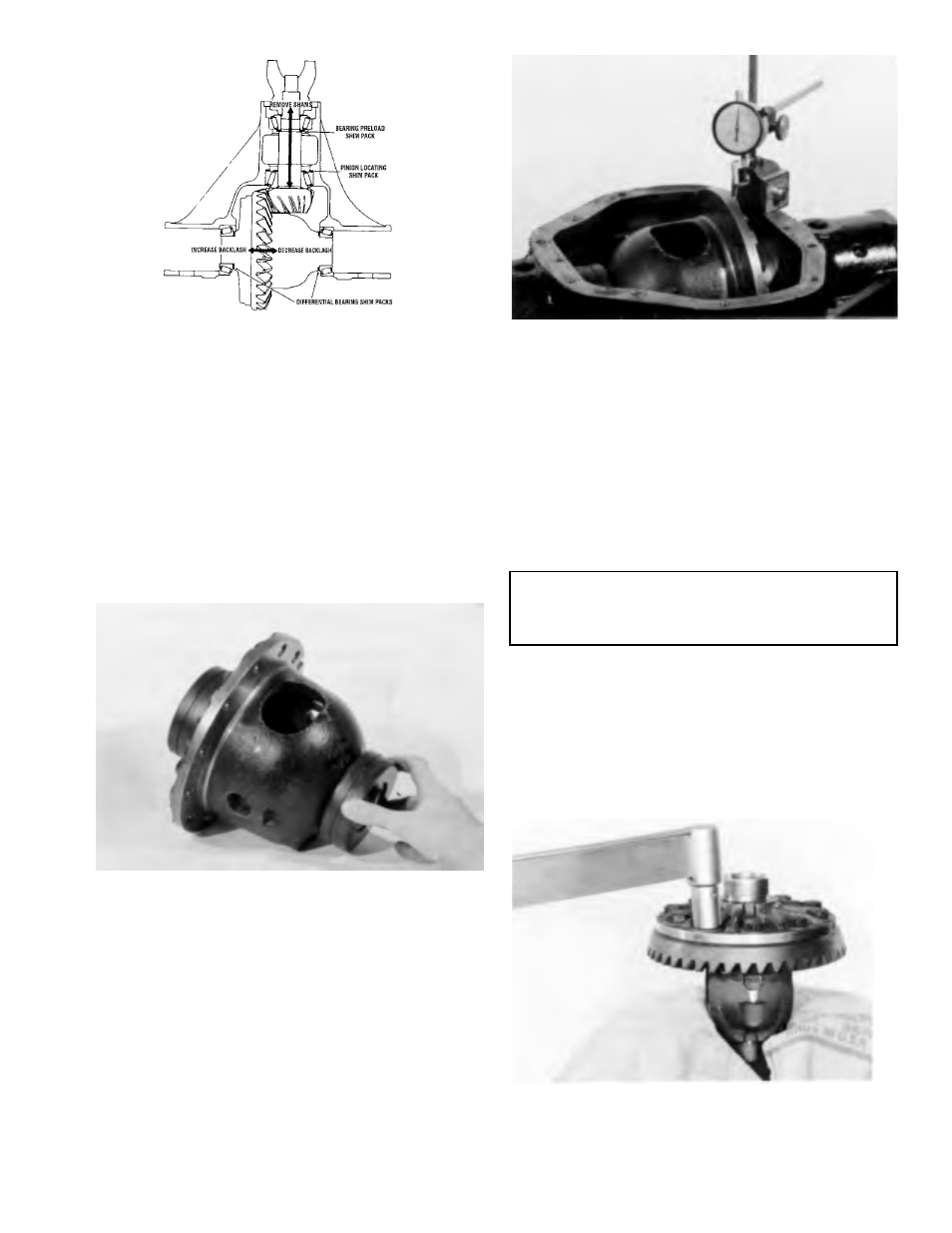

Figure 3-38

The illustration in figure 338 shows the arrow in the pinion

pointing in two directions. The direction pointing towards

the end yoke indicates that by removing pinion position

shims, the distance from the centerline of the axle to the

pinion button is increased giving a plus reading. The preload

shim pack does not effect the pinion depth setting. Arrows

on the ring gear illustrate the method to increase or

decrease backlash and differential bearing preload.

ASSEMBLY OF DIFFERENTIAL

Figure 3-39

Step (40) Assemble master differential bearings onto case.

Remove all nicks, burrs, dirt etc., from hubs to allow master

bearings to rotate freely.

TOOL: 6776 Dummy Differential Bearing Set

Figure 3-40

Step (41) Assemble the differential bearing outboard

spacers into the carrier housing, as removed in step 5,

figure 34.

Assemble differential case into carrier (less ring gear).

Mount dial indicator with a magnetic base as shown. Locate

tip of indicator on flat surface of case. Force differential

assembly as far as possible in the direction towards the

indicator. With force still applied, set indicator at zero (0).

TOOL: C-3339 Dial Indicator Set

NOTE

Dial indicator should have a minimum travel capability

of .200 (5.08 mm).

Force the differential assembly as far as it will go in

the opposite direction. Repeat these steps until you have

obtained the same reading. Record the reading of the

indicator on the worksheet, page 313. This reading will be

measurement “A”. After making sure the readings are

correct, remove indicator and differential assembly from

housing. Remove master bearings from hubs and set aside.

Figure 3-41

Step (42) Place case assembly in a vise. Be sure flange