Wheel bearing adjustment, Maintenance / adjustment, Periodic service – Spicer Drive Axles Service Manual Single Axles 2-Speed & Double Reduction User Manual

Page 9

Wheel Bearing Adjustment

Wheel bearings should be adjusted at

regular intervals using the following

procedure:

PREPARATION: Provide means to capture

lubricant that will escape when axle shafts

are removed. Remove axle shafts. Jack the

wheel to be adjusted clear of the ground.

After securely blocking the vehicle to prevent

rolling, release the parking brake, allowing

the wheel to rotate freely.

1.

Remove outer adjusting nut and doweled

(or tanged) washer.

2

. Visually inspect spindle for damage or

wear. Inspect the nut and spindle threads for

damage. Make certain that the nut turns

without binding by cleaning the threads and

applying a light coat of oil prior to adjusting

the wheel bearings. Inspect tanged washer

(if used). Replace washer if tangs are broken

or badly misshaped.

3

. Torque inner nut to 200 lbs.-ft.(272 N.m)

while

rotating the wheel. Loosen the nut

one full turn.

-

Re-torque to 50 Ibs.-ft.

(68 N.m). Back off nut 1/4 of a full turn.

4

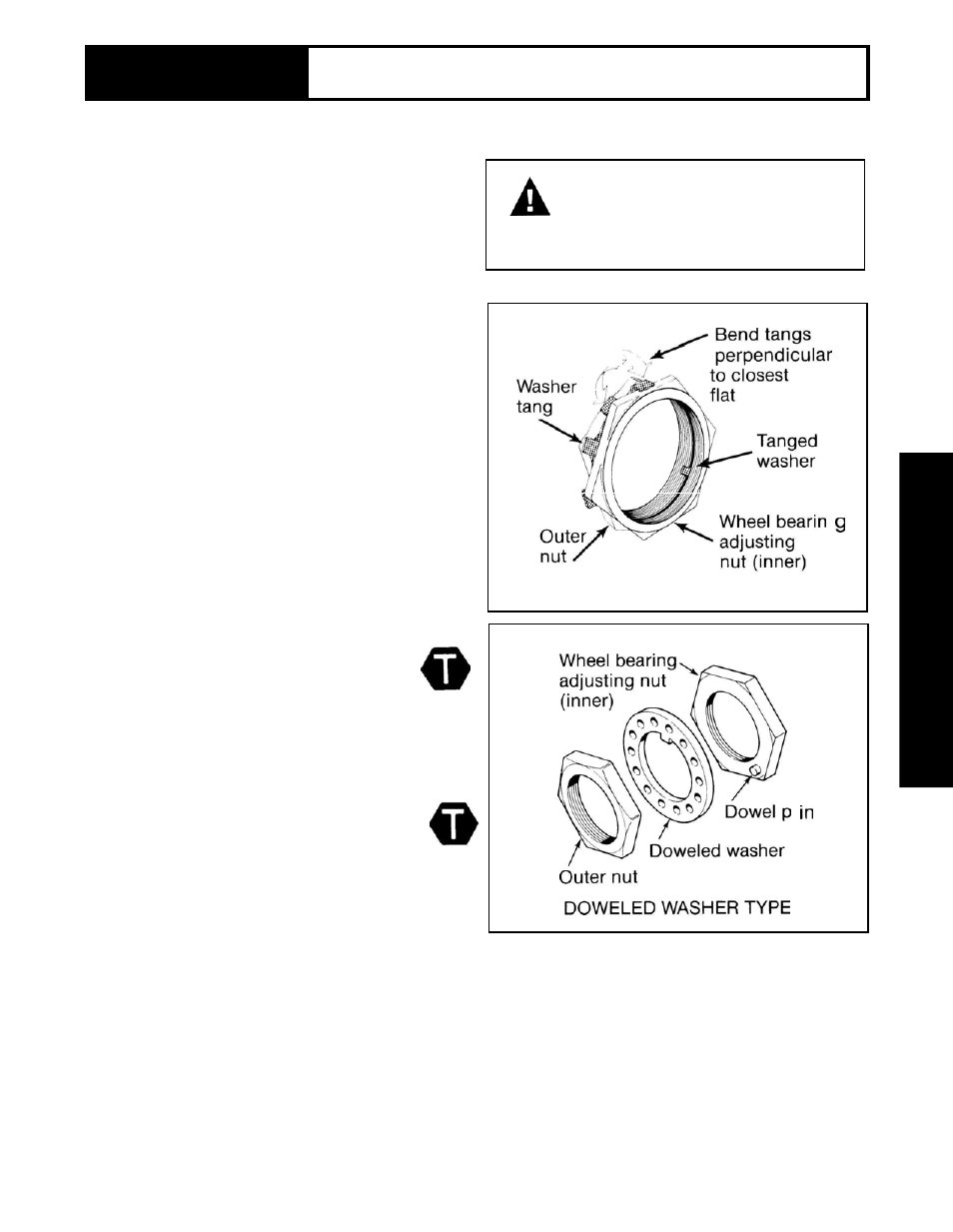

. Install doweled (or tanged) washer. If the

dowel pin and washer (or washer tang and

nut flat) are not aligned, remove washer, turn

it over and reinstall. For further alignment,

loosen the inner nut slightly.

5

. install outer nut and torque as follows:

l

Doweled washer type lock - 300 Ibs.-ft.

(408 N.m)

l

Tanged washer type lock - 250 Ibs.-ft.

(339 N.m)

This adjustment procedure should allow

TANGED WASHER TYPE

wheel to turn freely within .001" to .005"

6

. If using the tanged washer type lock,

(0.025 to 0.125 mm) end-play.

secure adjusting nuts by bending one wheel

NOTE:

The end-play should be measured

nut washer tang over each nut. Bend tangs

using a dial indicator. If the tires and wheels

over the closest flat perpendicular to the tang

are on the hub, prying the wheel end before

(see illustration).

making the end-play measurement will

7

. Reinstall axle shaft. Refill axle to proper

produce a more accurate reading.

lube level.

MAINTENANCE / ADJUSTMENT

Periodic

Service

Section

2

WARNING:

Never work under a

vehicle supported only by a jack.

Insure that the vehicle will not roll

before releasing brakes.

9